Stem Removal & Installation: Threadless

This article covers the full process of how to replace threadless stems, including choosing compatible components, proper spacer orientation, and final centering and headset adjustment.

Getting Started

- Tape measure

- Appropriately sized hex or Torx®-compatible wrenches

- Torque wrench or torque driver with appropriate bits

- Grease or threadlocker for stem bolts

- Assembly compound for carbon bars

- Toe straps/zip ties

- Rags

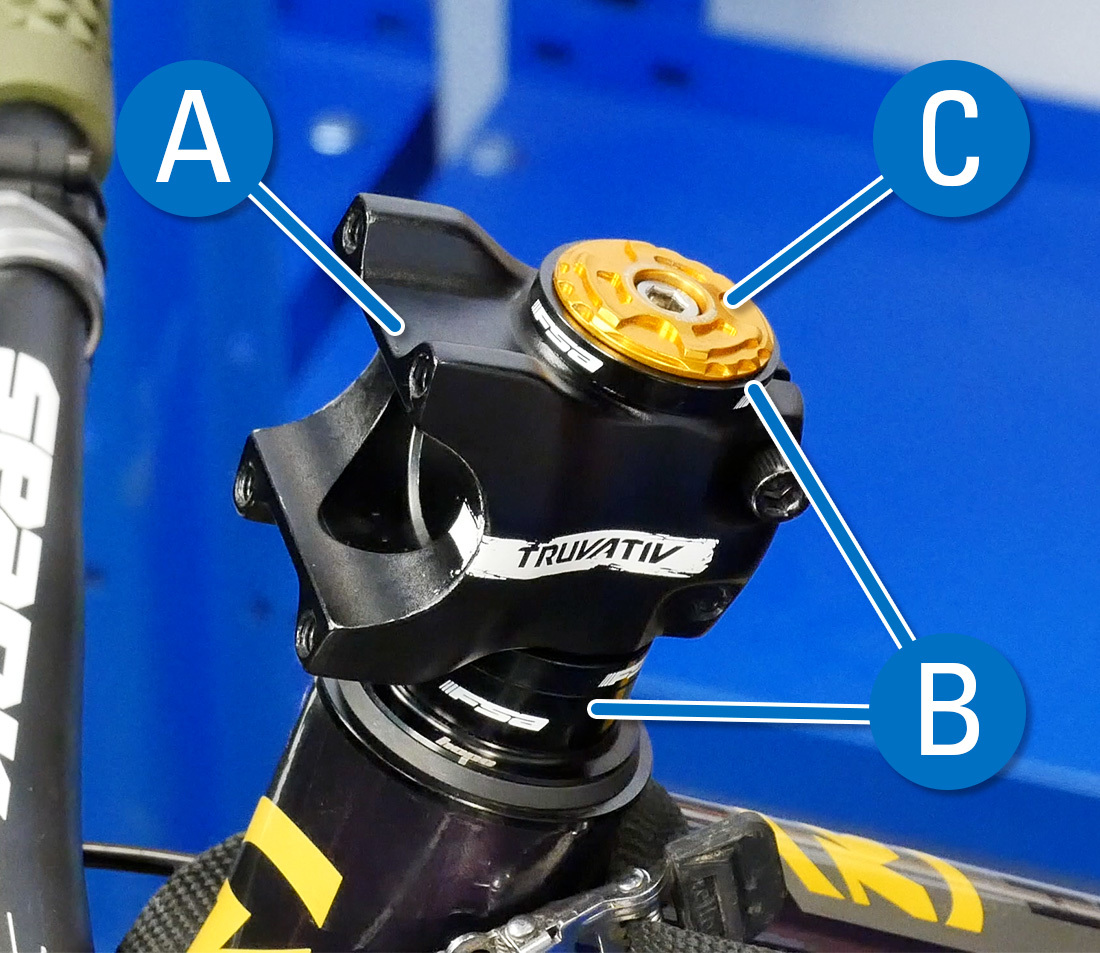

A “threadless” stem refers to a system where a fork with a non-threaded steerer tube extends through the head tube. A stem (A) then clamps around the outside of the steerer tube along with spacers (B) if necessary. Finally, a top cap (C) keeps everything in place and acts as a headset adjustment.

Many older bikes and some lower-end bikes have threaded steerer tubes. The stems used with these systems are referred to as “quill stems”. For more information, see Stem Removal & Installation: Quill Stems

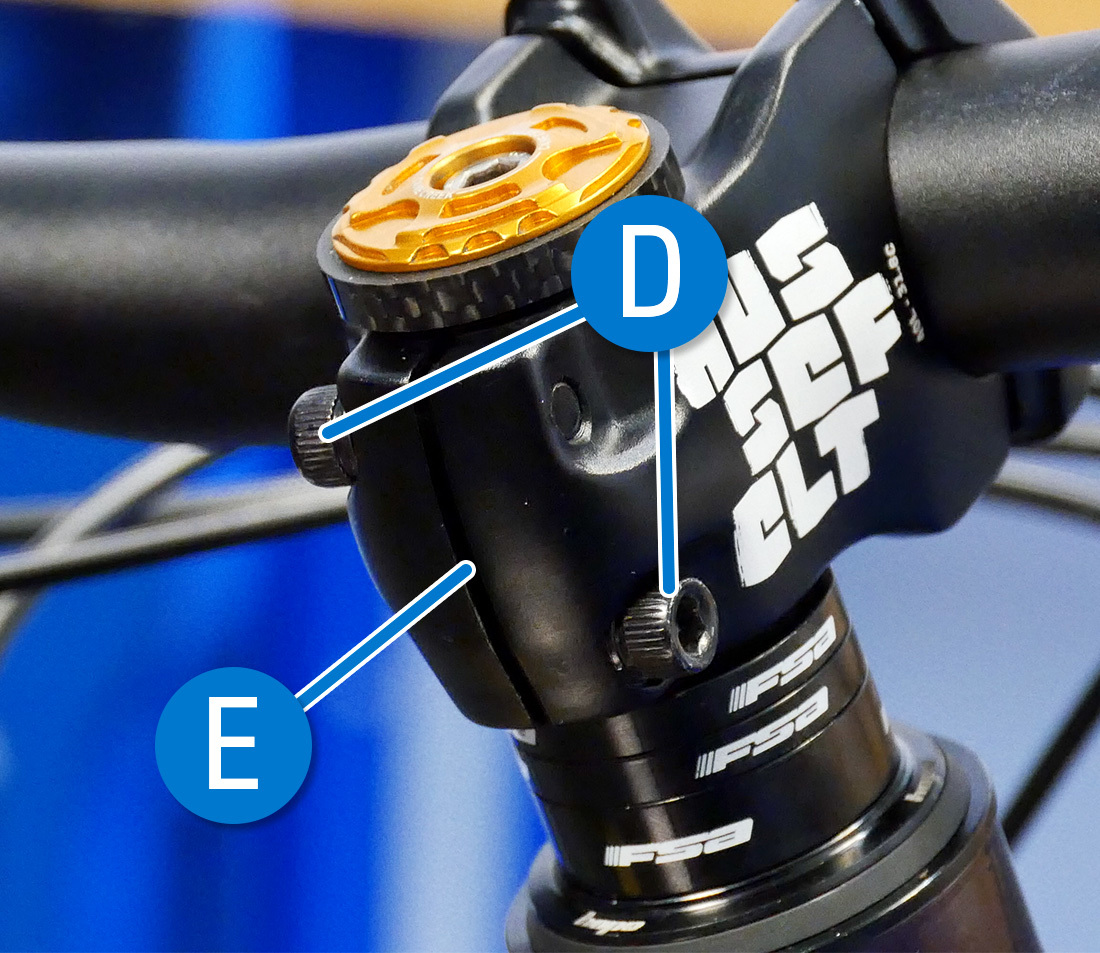

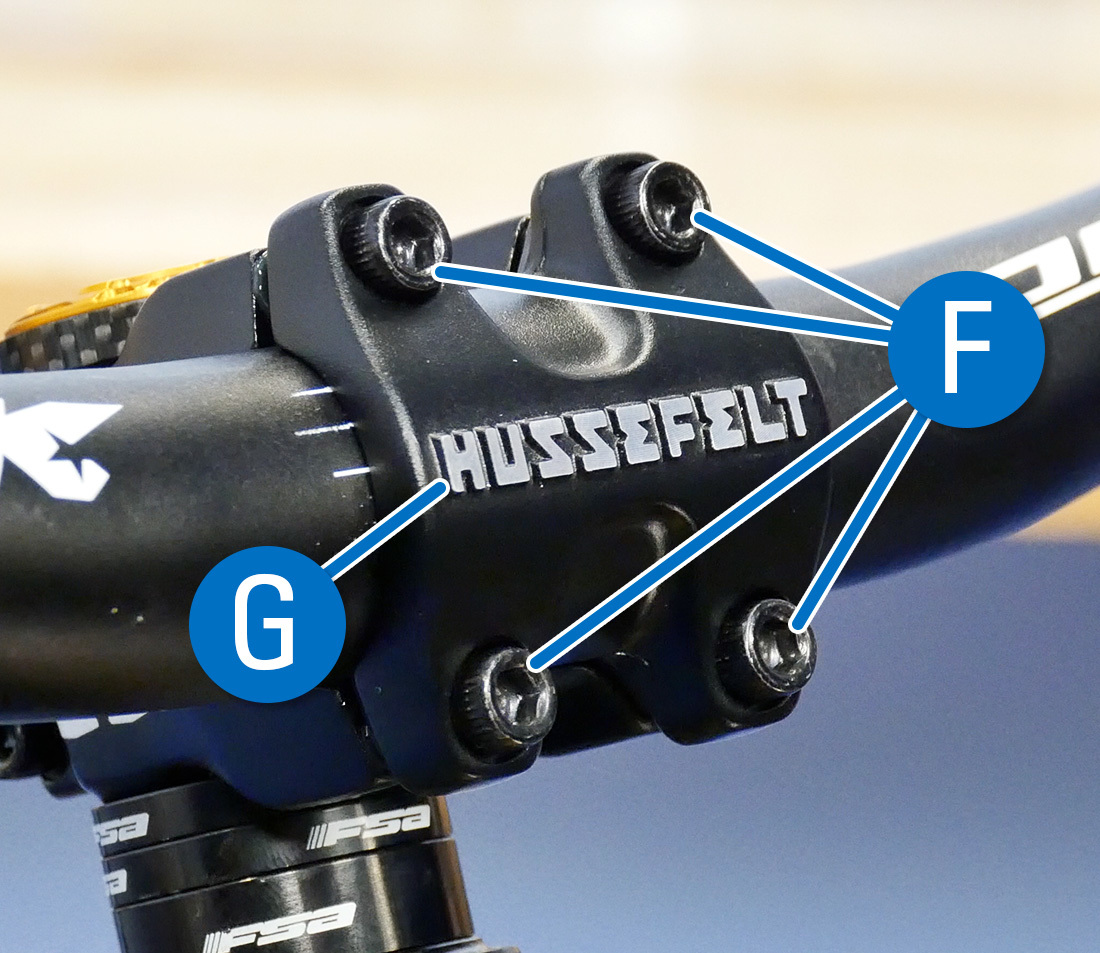

Threadless stems will typically have 1–3 pinch bolts (D) used in conjunction with a compression slot (E) to hold the stem to the steerer tube. They will also have 2–6 bolts (F) securing the faceplate (G), although in some cases they hook on with one side and bolt on with the other.

Pinch bolts (D) and Compression Slot (E)

Faceplate Bolts (F) and Faceplate (G)

Stems come in different steerer tube and handlebar sizes. It is wise to measure your components to ensure that you are installing or ordering the correct stem. Some common handlebar diameters are 22.2, 25.4, 26.0, 31.8, and 35mm. There are some outliers on some older bikes. Common steertube diameters are 1″, 1 ⅛”, 1 ¼” and 1 ½”.

To determine the diameters of the steerer tube and bar, measure right where the stem will clamp using a metric caliper. Be sure to be accurate as some clamp diameters are within fractions of a millimeter of each other and are not cross-compatible.

It is difficult to determine the clamp diameter of the stem by measuring it. The clamp diameter is typically engraved or labeled on the stem, but sometimes it is not. Incompatible components can be a safety hazard, so always double-check with the manufacturer for specifications and compatibility information.

Measure the center of the bar

Stem size is often labeled on the stem

Stems also come in different lengths — measured from the center of the steerer tube to the bar center — and angles — typically between 0 and 20 degrees. These measurements are generally marked somewhere on the stem or its packaging. Stems can be installed in an up or down position to adjust the bar height without changing spacer orientation. This is often referred to as positive and negative rise. When making drastic changes to the angle or length of the stem, changes to housing length may be required.

Stems are usually accompanied on the steerer tube by spacers. These spacers come in a multitude of different thicknesses, colors, and materials. They allow for height adjustment, and they also play a role in headset adjustment.

When installing a new stem it is important to pay attention to the height of the stem and the amount of spacers that you were running before. If you’d like to match the height of the original stem, measure from the top of the tire to the center of the handlebars and write it down for later reference. Note that a new stem may have a shorter or taller stack, which you will then need to account for with more, fewer, or different spacers.

Steering column spacers can be moved above or below the stem to change bar height.

This procedure can be done with the bike in a repair stand with the front wheel removed, or on the ground. It can be helpful to straddle the bike for stability.

Stem Removal

Begin by removing the old stem. Remove the faceplate bolts while holding the faceplate in place.

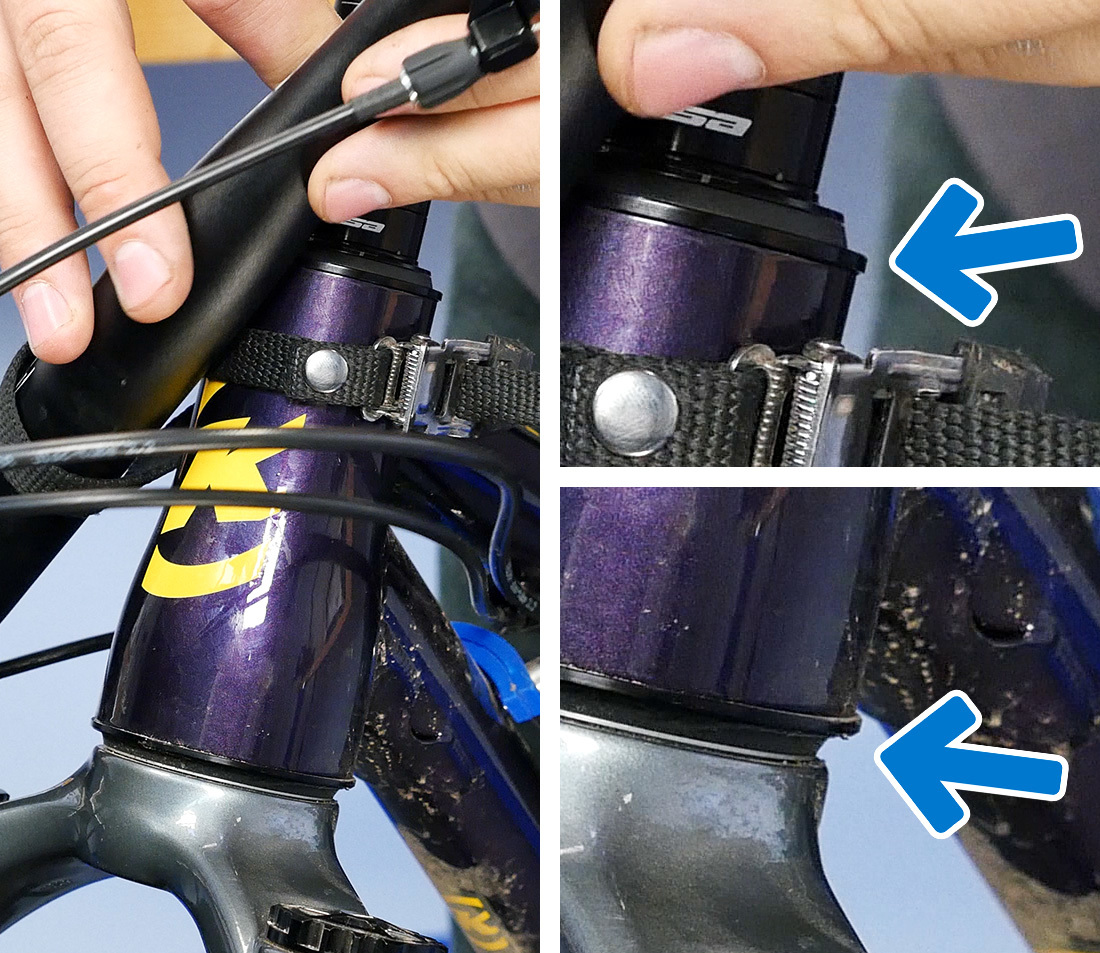

Once you have the faceplate off, the bars will be hanging free. It is good practice to use a toe strap or something similar to suspend the bars and keep the cable and housing from kinking.

Loosen the pinch bolts at the steerer tube. One full turn is more than likely enough.

Next we will remove the top cap, but before we do: note that it is currently the only thing keeping the fork from falling out of the bike. If you are working on the bike in a repair stand, use another toe strap or zip tie to keep the fork in place.

Loosen both pinch bolts

Second toe strap to keep fork in frame

Now loosen the top cap bolt, and remove the top cap. You should then be able to pull the stem free of the steerer tube.

Stem Installation

Install the new stem and spacers. Set the bike on the ground and ensure that all components are fully seated, with no gaps.

Configure the stem and spacers to the desired stem height. Compare to earlier measurement if so desired. If the new stem has a different stack height than the old one, you will need to rearrange spacers accordingly.

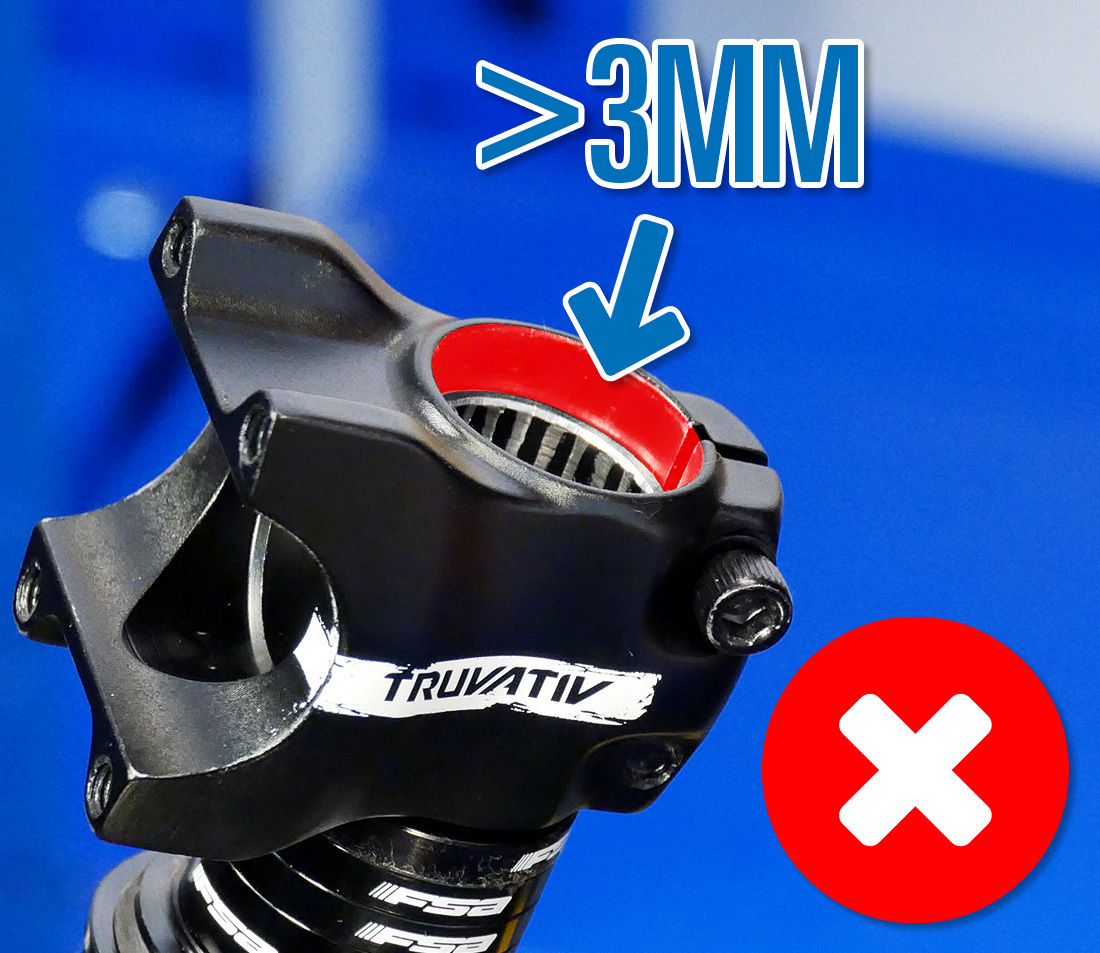

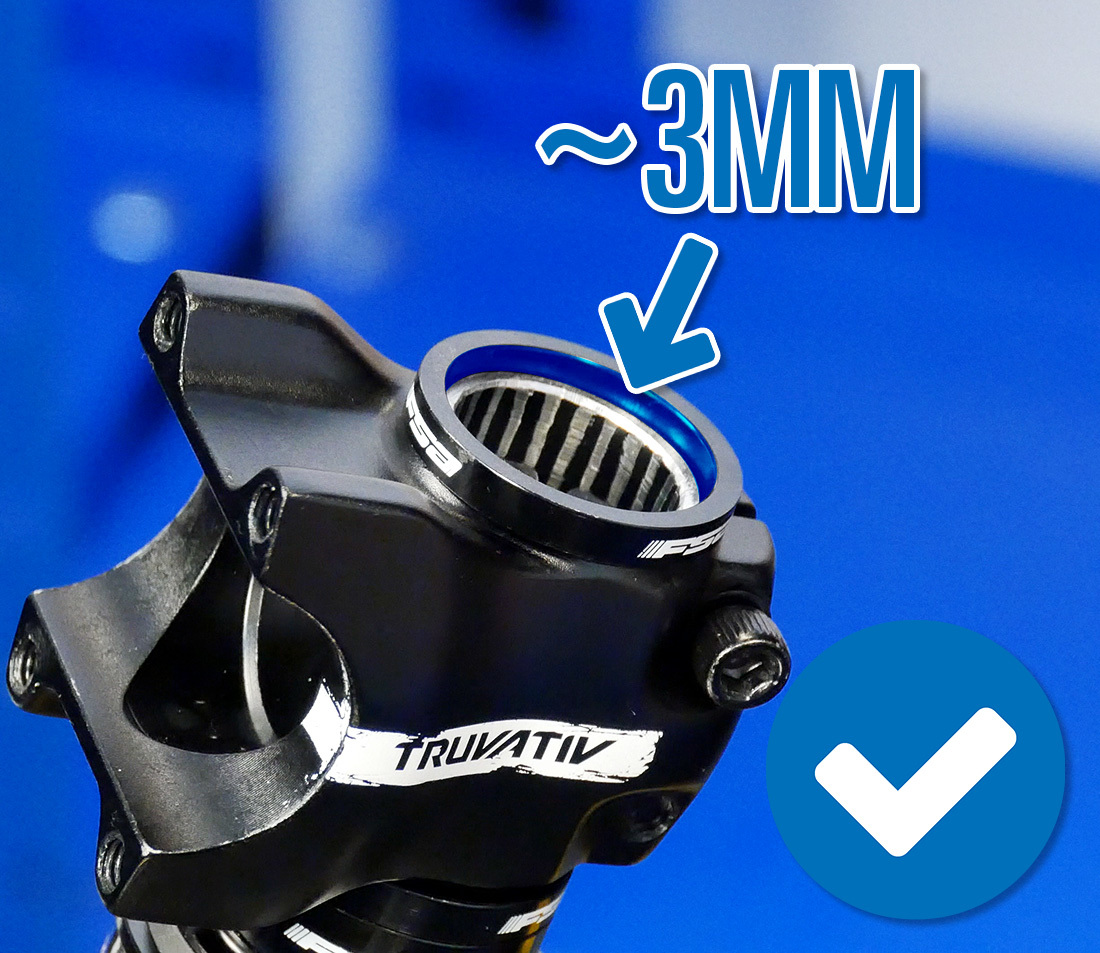

The stem or spacers should be slightly above the top of the steerer tube (approximately 3mm). If they are flush with or below the steerer tube, headset adjustment will be impossible. Acquire additional or differently-sized spacers to reach the appropriate height. It is also possible that the new stem is taller which may require you to remove a spacer.

Stack is too high — remove spacers

Stack is too low — add spacers

Proper spacer setup with stem on top of stack

Proper spacer setup with spacer on top of stack

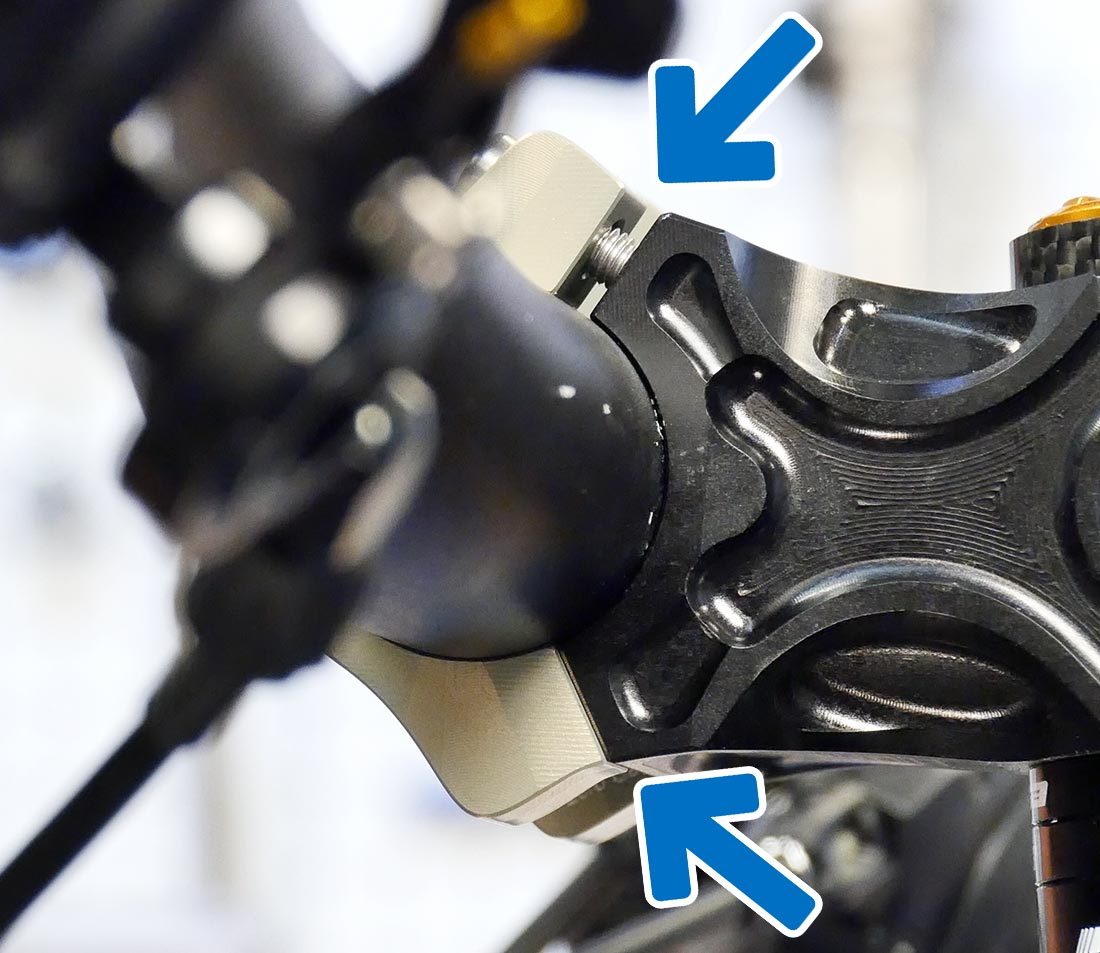

When dealing with a carbon steerer tube, it is critical to have the steerer tube go all the way through the stem, in order to reduce stress on the end of the steerer tube. It is then necessary to have a spacer on top of the stem.

Apply grease to the top cap bolt and install the top cap. The top cap sets the headset adjustment. Slightly snug this bolt for now — we will fine-tune this adjustment near the end of the process.

If you are installing a carbon bar, it is wise to apply an assembly compound such as Park Tool SAC-2 where the bar meets the stem. This will help create the needed friction between the bar and the stem to resist rotation. It will also act as a barrier between the bar and stem materials.

Tighten the top cap until you meet resistance

Spread the assembly compound over the area that is covered by the stem

Apply grease or threadlocker to the faceplate bolts. Place the faceplate over the front of the bars and thread in the bolts, but do not tighten them fully.

These bolts should be tightened evenly and the gap between the stem and the face plate should typically be even on the top and bottom. This reduces stress on the bolt heads.

There are a few stem designs that require that the top or bottom bolts to be fully tightened before the other side. This style of stem is often labeled accordingly. Inquire with the manufacturer for more info.

Typical stem designs require even threading of the faceplate bolts

Some designs require the top or bottom to be threaded in completely

Before fully tightening the bolts, stand over the bike to set the bar roll to your preference. You will also want to make sure the bars are centered in the stem at this point.

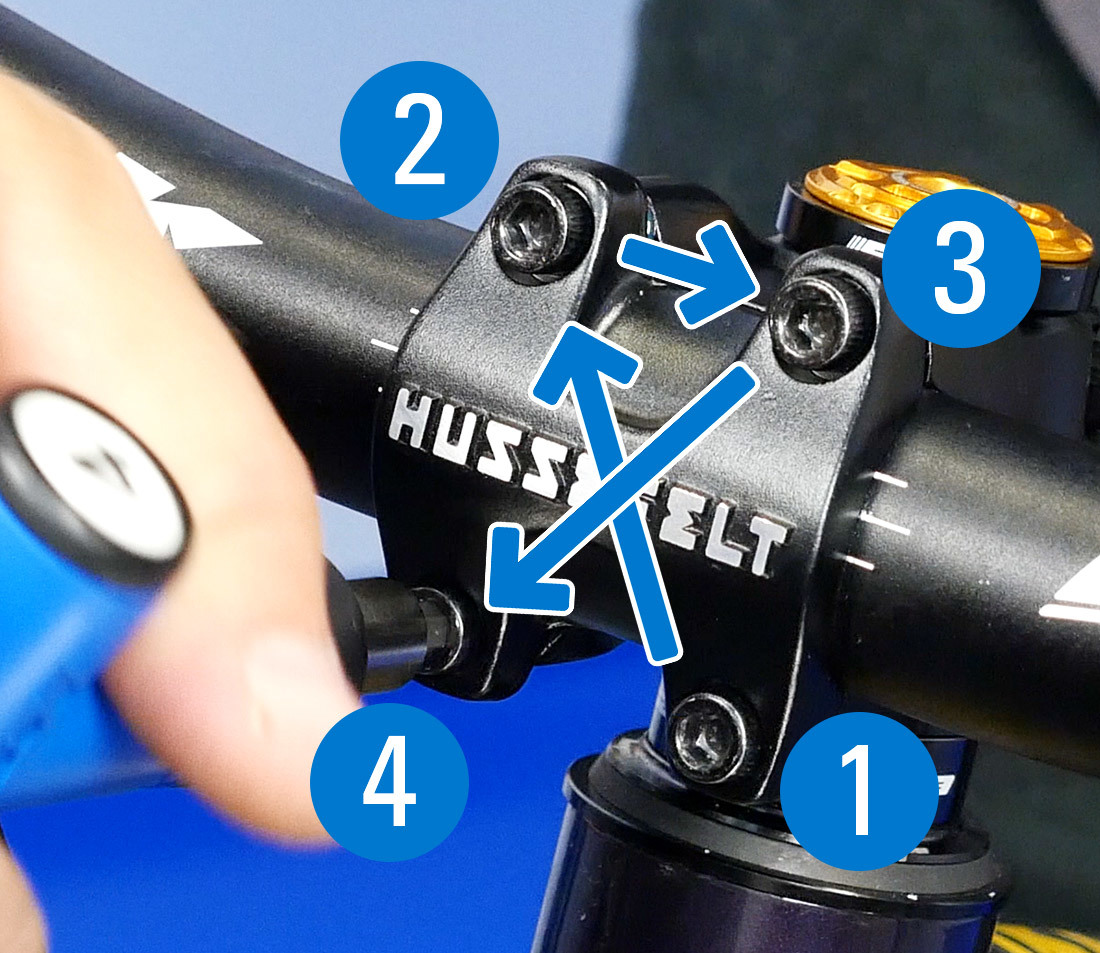

Fully tighten and torque the face plate bolts in an X pattern. A typical torque spec is 4–6Nm.

Many bars have markings to aid in centering

Tighten and torque in an "X" pattern

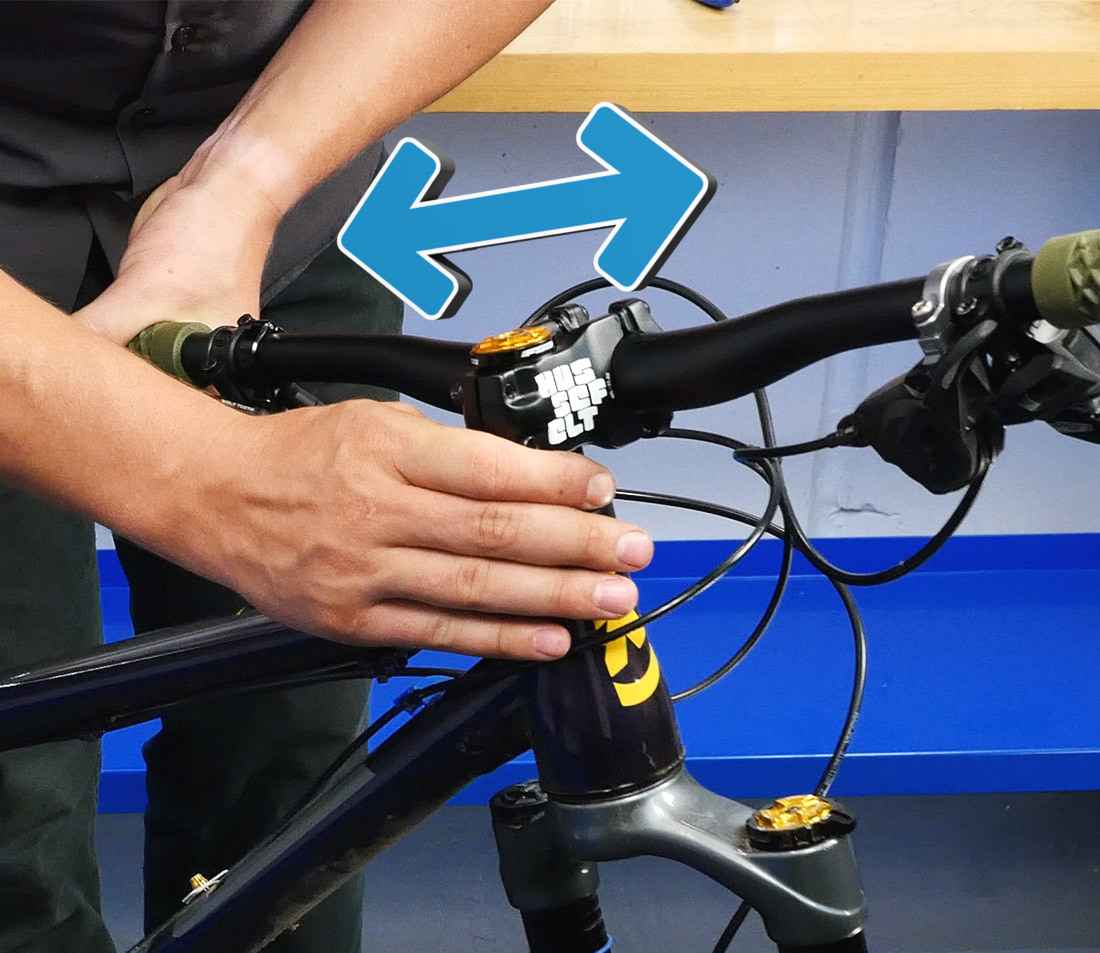

Snug the top cap down until there is slight resistance. Test the headset adjustment by lifting the bike and pushing the bars back and forth — the bars should turn freely with very little resistance. If the motion of the bars feels sticky or hesitant, loosen the top cap 1/8th of a turn and test again.

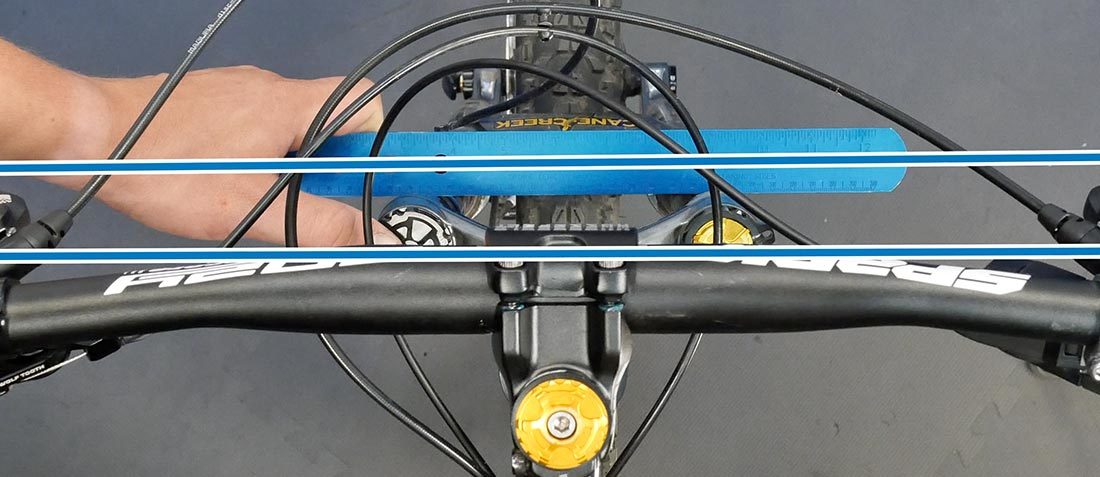

Next, straighten the handlebars. It can be helpful to use a ruler or other long object against the fork legs as a reference point.

Snug the pinch bolts. Test the headset adjustment by holding the front brake firmly and rock the bike back and forth. Put your fingers on the top bearing cover of the headset and the top cup of the headset and feel for play, which can be felt as a slight knock. It may also help to turn the handlebars 90 degrees — this isolates fork play.

If you feel play, loosen the pinch bolts, tighten the top cap another 1/8th turn, re-tighten the pinch bolts, and check again. continue until the play is gone. Verify that the bars still turn freely with little resistance.

Torque the pinch bolts. A typical torque spec is 4–6 Nm.