Handlebar Tape Installation (Drop Bars)

This article will address wrapping drop style handlebars. For installation of flat handlebar grips see Flat Bar Grip Installation.

Preparation

Wrapping drop handlebars is a skill that requires practice and patience. The finished job should look tidy and clean for the user. Wrapping also provides a good time to replace cables and housing. Additionally, with the bar tape off, it is an opportune time to move the levers up or down the bars as desired. If you are using white or light colored tape, wash hands thoroughly or wear MG-2 gloves to keep the tape clean.

When re-wrapping bars, begin with an inspection. Adhesive padded tapes may leave lumps as they are removed, and these should be cleaned off. Housing and cables are often routed under the tape. Use thin adhesive tape such as electrical tape or narrow strips of fiber tape to hold the housing in place.

Handlebar tape can be made of cloth, cork, padded vinyl or other synthetic materials. Tape brands will vary both in how it stretches and in its strength when pulled in tension over the bar. If you are unfamiliar with the brand and type of tape, grab at the end and pull on a short section to get a sense of the tensile strength. This may help prevent inadvertent breaking while in the middle of a wrap.

Arrange the work area so tools and parts are close at hand. Besides the bar tape, you will need scissors or a sharp knife, tape to hold the housing to the bars, finishing tape such as electrical tape for the end and the bar end plugs. Pre-cut the finishing tape about 8 to 10″ long (20 to 25cm) and stick the ends to the top tube. Lastly, pull back on each hood to expose the lever body.

Wrapping should begin at the end of the handle bars and work upward. Starting at the top of the bars and working downward will result in rolling the edge of the tape down as the user presses on it during riding.

Before starting the wrap, consider where to end the tape. Some handlebars are made with an obvious sleeve in the middle and this can be used as end of the taping. Some bars have a long taper and lack a clear place to end. In these cases, decide where to end by how much tape is needed for comfort and by the look of the finished result.

Wrapping Procedure

During stressful riding, the rider’s hands tend to apply a torque to the bars. Matching the direction of wrap helps minimize loosening of the tape. As seen from the back (the rider’s point of view), the stress is outward on each side of the drops. Consequently, the right side should be wrapped in a clockwise direction while the left side should be counter-clockwise.

However, when riding on the tops of the bars, it is the habit of many cyclists to pull back on their hands while under stress. To match this torque, the direction of wrap will need to be reversed above the levers.

Start the tape at the bottom side of the bar end. Extend one wrap past the end. Pull with tension and wrap three or four times as you move forward on the bar. Tuck the extra tape into the bar end and insert the bar end plug. Inspect that the plug is tight and the tape looks tidy. Correct as needed before proceeding.

If the tape you are installing uses an adhesive strip, it will be in the middle of the tape. Pull with tension and overlap as you proceed so the adhesive is on the bare handlebar just past the previous wrap of tape. For non-adhesive tapes, overlap so approximately half the tape is on bar.

Continue to maintain tension on the tape by pulling as you wrap, using care not to apply too much force, breaking the tape. Cloth tape especially may need to be worked smooth, pulling and backing up until it lies down nicely on the bar, especially at the corners. Inspect as you wrap and avoid leaving a gap in the tape.

The tape wrap must pass the lever body. The simplest and easiest method at the brake levers is simply to extend the wrap as you reach the body. This leaves a small visual gap in the wrap. However, this technique will result in a less desirable rotation direction of the wrap along the top of the bars.

Alternatively, use the lever to reverse the direction of wrap. By wrapping over the inside of the body, and then continuing up the bar, the tape is now going the opposite rotation. It will be wrapped from front to back, matching the direction of stress by the rider when on the top.

An additional technique is to use a small piece of bar tape to cover the bar at the lever strap. These extra pieces are sometimes included with the tape. The hood should be pulled forward to expose the lever body. When the tape is close to the body, place the end-piece over the back of the lever.

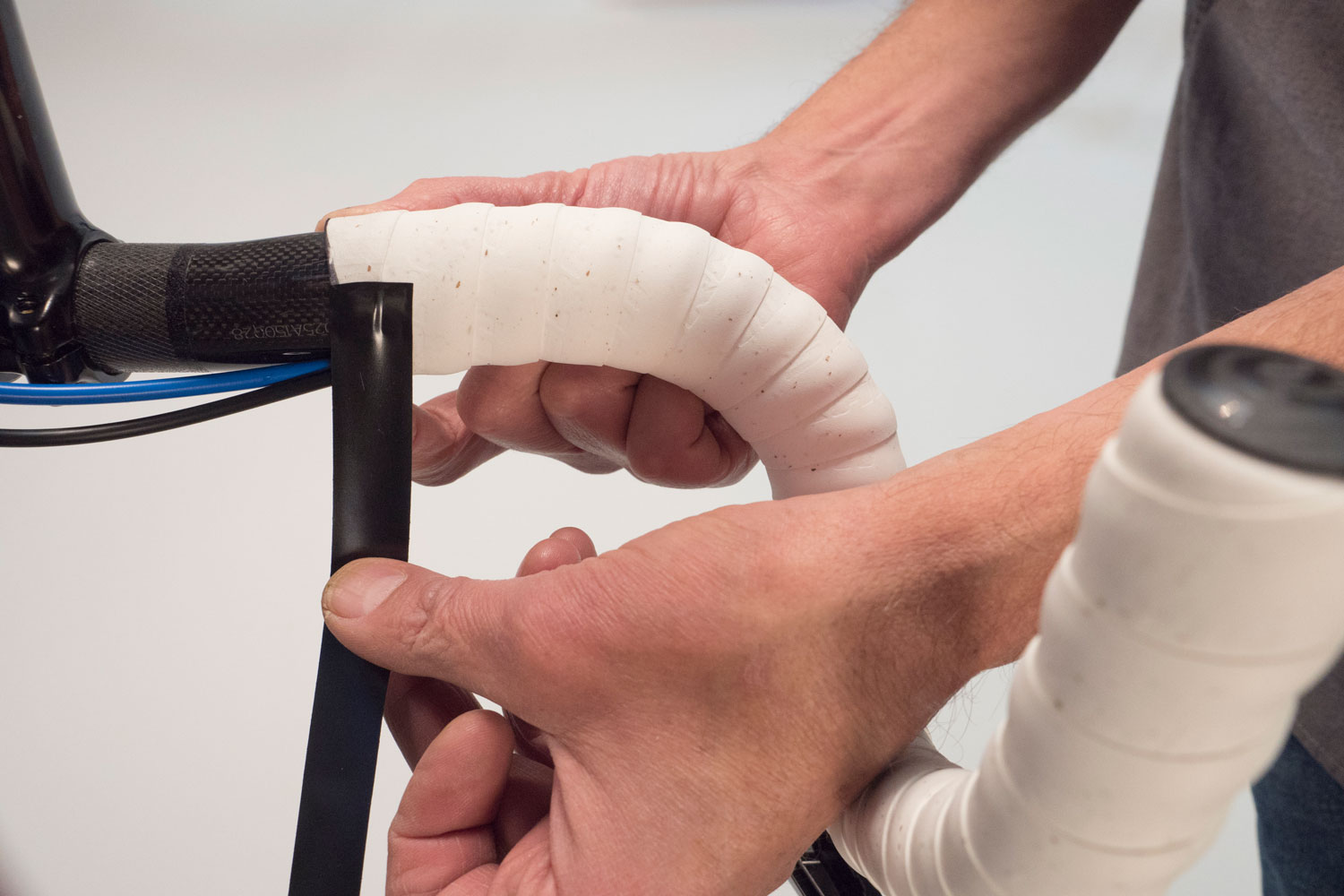

Continue to wrap up and around the small piece and the lever, plus one or two additional wraps past the lever. Fold the hoods back and inspect the tape for gaps. Correct any errors now by unwrapping the tape and working the area again.

Still another technique comes from a time when bar tape was relatively thin.The tape is wrapped up and around the lever, then back below the lever, making a “figure 8.” This extra wrapping will take more tape length, and can leave a large bulbous mass at the lever.

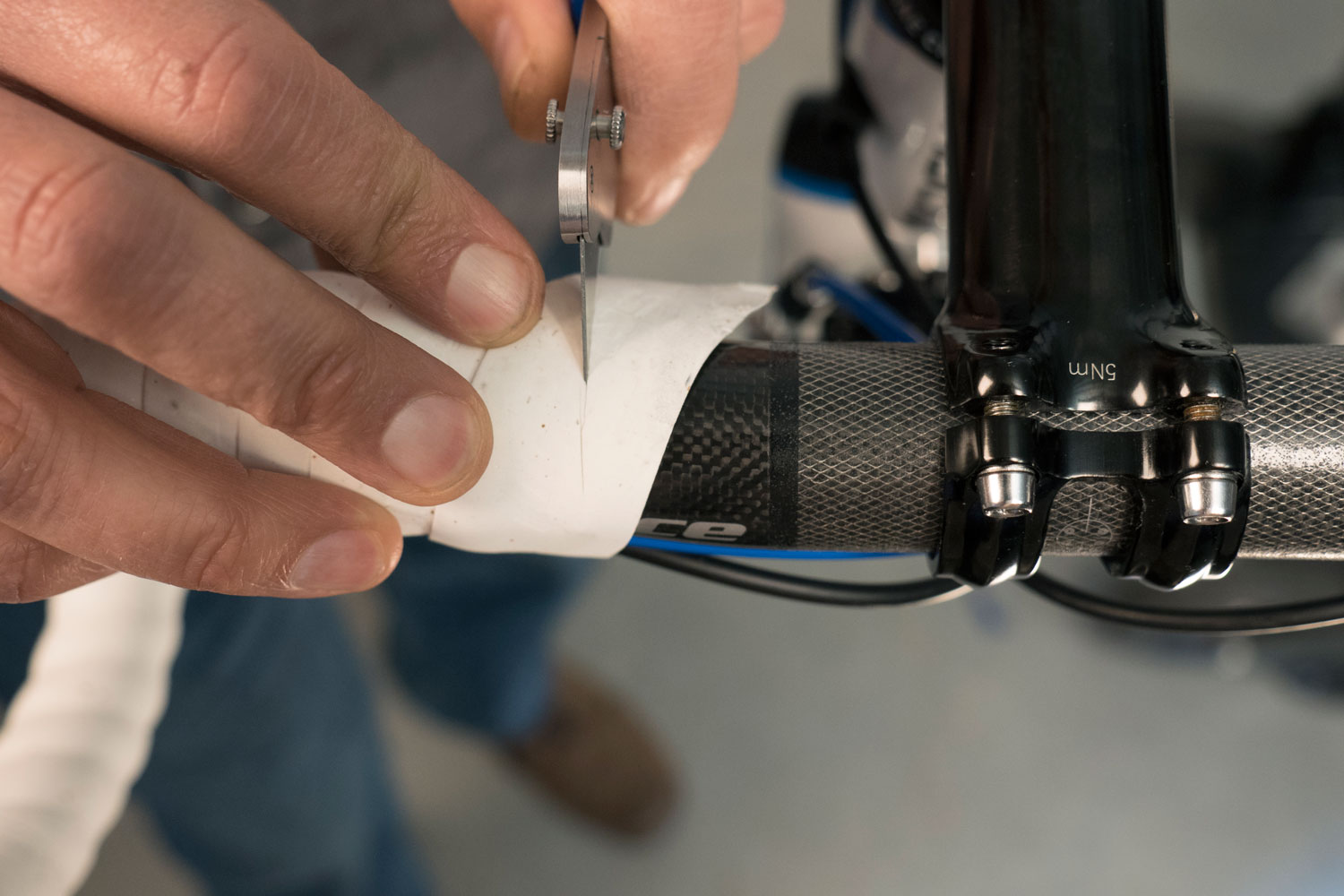

Keep wrapping toward the bar center. Maintain a consistent amount of wrap and wrap past your ending point at least two wraps. Use scissors or a sharp knife held square to the bars and score or mark the tape along the line where it should be ending.

NOTE: Use caution when working on carbon fiber handlebars. Do not make deep cuts into the fibers of carbon tubing.

Back tape off two wraps and find your scoring or cut mark. Use scissors to extend the cut all the way through the tape. Maintain the line and angle shown by the cut and cut tape cleanly and evenly. Wrap the tape on to the bar again. Trim the tape end so that it will finish at the bottom of the handlebar.

Use your piece of finishing tape to hold and cover the tape, wrapping in the same direction as the tape. Start the finish tape at the bottom of the bar. Wrap with tension using care to maintain a straight wrap, laying the tape down without wrinkles. Wrap two or three times around the bar and cut finish tape end so it will also end at the bottom of the bar.

Wrap the other bar as a mirror image. Remember—the starting direction on the lower drops should correspond to the direction of stress by the rider.

Additional Techniques

Here are some advanced techniques possible when wrapping a bar. It is often necessary to practice different techniques and see what works best for you and your customer.

A useful technique—especially for competitive cyclist—will help should the tape become torn or ripped, as can happen in a crash. Use either a strong double-sided sticky tape (such as carpet tape), or to turn some electrician’s tape inside out for the lower few inches of the bar. This is the area where bar tape tend to become damaged from falls and abrasion. Wrap over this with normal technique.

Some bar end plugs expand inside the ends to hold secure. It can make a cleaner tape beginning to first install these plugs, and then begin the wrap. Cut a taper at the end of tape. This allows the tape a smooth and even beginning, rather than a lump from the extra tape.

Using white tape when finishing with black electricians tape can leave a white edge showing. Use a black permanent marker to color the tape edge for a nicer look.

Finishing tape can, with time, begin to pull up. Use a soldering iron or a heated spoke end to “weld” the finish tape to help prevent loosening. Just two or three “tacks” with heat under the bar where the tape is ended is all that is needed.

Tack weld the finishing to prevent loosening