Cutter Selection Guide for Reaming, Tapping & Facing

This article contains an array of tables to assist in choosing the correct tools, cutters and spacers when reaming, tapping, or facing bicycle frames. The products referenced in this article can be found under the Frame & Fork Tools category.

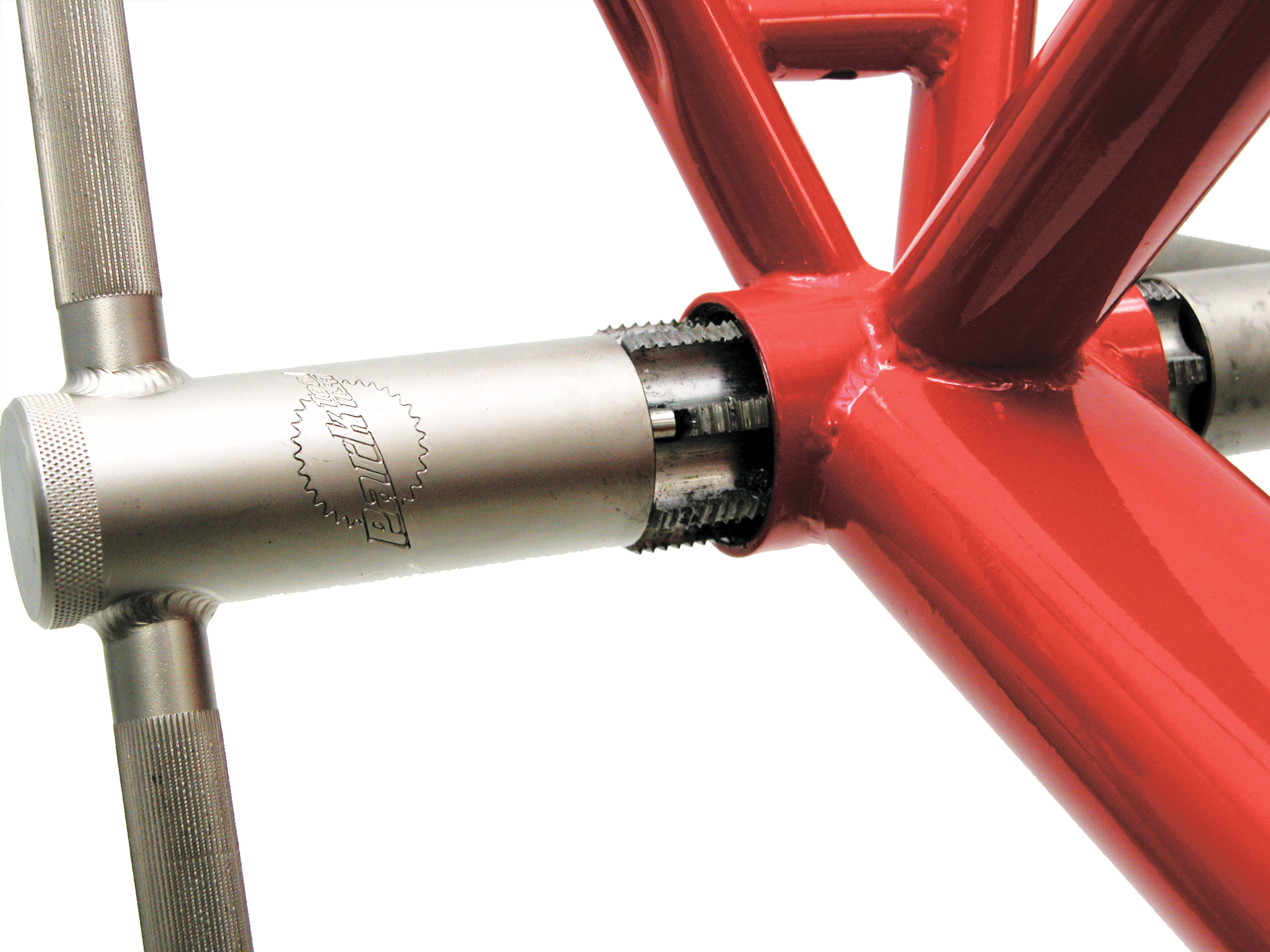

Bottom Bracket Shell Machining

Tools Required for Tapping and Facing:

The BTS-1 is capable of tapping and facing threaded bottom bracket shells, and includes the #691 & #692 taps and #690 facer.

The BFS-1 is purpose-built specifically for facing threaded bottom bracket shells, with a tension spring system for added pressure to the facer. It includes the #690 facer and #681 & 682 bushings.

| BB Standard | Shell Dim. | Tap & Face | Face Only |

|---|---|---|---|

| Threaded English | 33.7 mm ID | BTS-1, 690, 691, 692 | BFS-1 or BTS-1, 690, 681, 682 |

| Threaded Italian | 35 mm ID | BTS-1, 690, 693 (2 required) | BFS-1 or BTS-1, 690, 688 (2 required) |

| Threaded T47 | 46 mm ID | BTS-1, 690-XL, 647L, 647R | BFS-1 or BTS-1, 690-XL, 648L, 648R |

Tools Required for Reaming and Facing:

Threadless bottom bracket shells can be machined with various racers, facers, pilots and centering cone adapters. All options require the use of either the HTR-1, HTR-1B and HTR-HS.

| BB Standard | Shell Dim. | Ream & Face | Ream Only | Face Only |

|---|---|---|---|---|

| BB30, PF42 | 42 mm ID | 750.2, 690-XL, 752 | 750.2, 752 | 750.2, 690-XL, 764 |

| PF30, PF46 | 46 mm ID | 750.2, 690-XL, 791 | 750.2, 687, 791 | 750.2, 690-XL, 791P |

| BBright Direct Fit | 42 mm ID | 750.2, 690-XL, 752 | 752, 750.2 | — |

| BBright Press Fit | 46 mm ID | 750.2, 690-XL, 791 | 750.2, 687, 791 | 750.2, 690-XL, 791P |

| 386 Evo | 46 mm ID | 750.2, 690-XL, 791 | 750.2, 687, 791 | 750.2, 690-XL, 791P |

| BB86/92, PF41, PF24 | 41 mm ID | 750.2, 690-XL, 744 | 750.2, 687, 744 | 750.2, 690-XL, 764 |

Head Tube Machining

Tools Required for Reaming and Facing:

All options require the use of either the HTR-1, HTR-1B and HTR-HS plus correct accessory.

| Headset Std. | Headset Cup Dim. | Head Tube Dim. | Ream & Face | Face Only |

|---|---|---|---|---|

| 1″ External Cup (EC29) | 30.00–30.10 mm OD | 29.85–29.90 mm ID | — | 762, 690 |

| 1″ External Cup (EC30) | 30.20–30.30 mm OD | 30.05–30.10 mm ID | 751.2, 690 | 763, 690 |

| 1⅛″ External Cup (EC34) | 34.05–34.15 mm OD | 33.90–33.95 mm ID | 754.2, 690 | 765, 690 |

| 1¼″ External Cup (EC37) | 37.05–37.15 mm OD | 36.90–36.95 mm ID | — | 766, 690 |

| 1.5″ External Cup (EC49) | 49.70–49.75 mm OD | 49.57–49.61 mm ID | 758.2, 750.2 | 767, 690-XL, 750.2 |

| 1⅛″ Internal Cup (ZS44) | 44.05–44.10 mm OD | 43.95–44.00 mm ID | 788, 690-XL, 750.2 | 768, 690-XL, 750.2 |

| 1.5″ Internal Cup (ZS56) | 55.99–56.04 mm OD | 55.90–55.95 mm ID | 789, 690-XXL, 750.2 | 790, 690-XL, 750.2 |

| 1⅛″ Integrated Upper (IS41) |

no cup | 41.10–41.20 mm ID, 3.1–3.2 mm Depth |

756S.2, 690-XL, 750.2 | — |

| 1⅛″ Integrated Lower (IS41) |

no cup | 41.10–41.20 mm ID, 6.9–7.0 mm Depth |

756S.2, 690-XL, 750.2 | — |

| 1⅛″ Integrated (IS42) | no cup | 41.95–42.05 mm ID, 2.8–3.0 mm Depth |

761S.2, 690-XL, 750.2 | — |

| 1⅛″ Integrated (IS42) | no cup | 41.95–42.05 mm ID, 6.6–6.8 mm Depth |

761S.2, 690-XL, 750.2 | — |

| 1¼″ Integrated (IS47) | no cup | 47.05–47.10 mm ID | 799, 690-XL, 750.2 | — |

| 1.5″ Integrated (IS52) | no cup | 52 mm ID | 738, 690-XL, 750.2 | — |

Fork Threading

Tools Required for Fork Threading:

The FTS-1 Fork Threading Set includes parts #606 and #610 for threading 1″ x 24 tpi forks. Dies and guides for the 1⅛″ x 26 tpi and 1¼″ x 26 tpi standards are available separately.

| Fork Thread | Required Die | Required Guide |

|---|---|---|

| 1″ x 24 tpi | 606 | 610 |

| 1⅛″ x 26 tpi | 607 | 611 |

| 1¼″ x 26 tpi | 608 | 612 |

Fork Crown Race Cutting

Tools required for Fork Crown Race Cutting:

The CRC-1 is designed to machine fork crown race seats. It includes the necessary bushings and cutters for 1″ and 1⅛″ forks.

The CRC-15 is used in conjunction with the CRC-1 to machine crown race seats on forks with a 1⅛″-to-1½″ taper.

| Fork Size | Crown Race Seat | Required Tools |

|---|---|---|

| 1″ | 26.5 mm | CRC-1 |

| 1″ | 27.1 mm | CRC-1 |

| 1⅛″ | 30.1 mm | CRC-1 |

| 1⅛″-to-1.5″ Tapered* |

30.1 mm | CRC-1, CRC-15 |

*Maximum taper length is 4.25 inches.

Misc. Tapping Applications

Tools Required for Tapping:

Park Tool offers a full line of taps for crank arms and various frame applications, as well as tap handles for ease of use. The TH-1 and TH-2 fit most common bicycle taps, including the Park Tool taps in the table below.

| Application | Thread | Required Tap |

|---|---|---|

| Pedal tap | 1/2″ x 20 tpi | TAP-3 (set of 2) |

| Pedal tap | 9/16″ x 20 tpi | TAP-6 (set of 2) |

| Rear wheel dropout alignment screws |

M3 x 0.5 | TAP-7 |

| Water bottle, toe clips, fender and rack bosses |

M5 x 0.8 | TAP-8 |

| Cantilever brakes, large fender bosses |

M6 x 1 | TAP-9 |

| Derailleur hanger | M10 x 1 | TAP-10 |

NOTE: The standards listed in these tables are for the components that can be machined using Park Tool products. This page is not an exhaustive list of standards used in the bicycle industry. Parts should always be accurately measured to ensure the correct tools are used.