Pedal Bushing Repair Kit Procedure

This article will review the repair of stripped pedal crank threads using the pedal bushing repair kits. NOTE: Park Tool does not make or sell a pedal bushing repair kit. These kits are expensive and in most cases arm replacement in the best option. This article is offered only as an explanation of the process.

Getting Started

Bicycle cranks are typically aluminum. If the pedals threads are over tightened, the threads in the crank may fail or “strip” (figure 1). It may also occur that if the pedal was under tightened, and the bike is used, the pedal axle will wiggle and move in the threads. This can also ruin the crank threads as the pedal works its way out of the crank and falls off. One repair option is of course to replace the crank. However for some cranks it possible to use a pedal bushing thread repair system. NOTE: This repair works best with cranks make of solid aluminum. This repair is not recommended for hollow arms or carbon fibers cranks.

The bushing thread repair systems consist of a kit (figure 2). There will be two special oversized taps plus bushings that are left-hand and right-hand threading. The taps include a long pilot section that acts as a reamer to remove any remaining thread inside the crank and to size the hole correctly for the larger threading.

When thread standards are described, it is from the outside diameter of the thread, which is the external thread. Bicycle pedals are commonly a 9/16″ x 20 threads per inch. The inside diameter of the internal thread (the “nut”) must be smaller. Measured in millimeters, the OD of the pedal is typically 14.2mm. For cranks the internal thread is nominally 13mm. This allows overlap of the thread. Failed internal threads will look flattened and have a larger inside diameter (figure 3).

The pedal bushing repair kit taps will increase the size of the crank thread to accept a bushing of 5/8″ x 20 TPI threading. The inside of this pedal bushing is sized to accept the 9/16″ x 20 TPI bicycle pedal thread standard. This can be a good repair when done correctly. However, the pedal should not be over torqued even with the bushing in place. The stress of tightening is ultimately still on the aluminum threads of the arm.

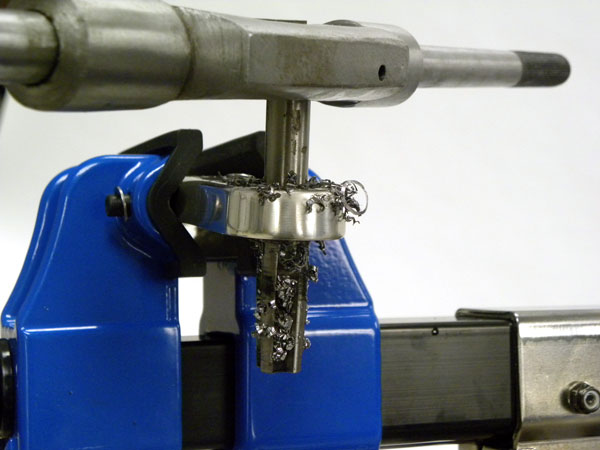

The crank must be firmly head for tapping. Many modern arms have tapered and odd shapes and are difficult to hold in a bench vise. It can be more useful to the the repair clamp to hold the arm for work.

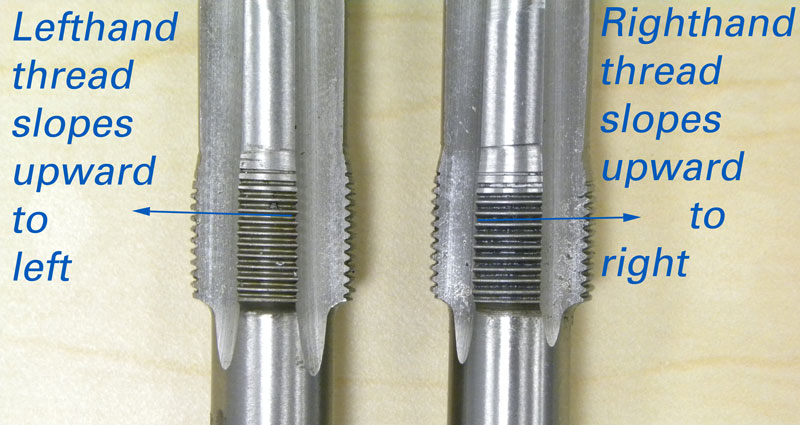

Bicycle pedals threads come in a RIGHT and LEFT hand threading. The right side, as seen from the riders point of view, is a right-hand thread and will cut clockwise. The left side is a left-hand thread and will cut counter-clockwise. The taps are usually marked but use care to correctly identify the cutting direction and confirm which crank should get which tap (figure 4).

Repair Procedure

Mount the tap in a tap handle. Tap handles allow even pressure to applied during the cut. Do not attempt this repair using an adjustable wrench.

The reamer section of the tap is tapered (figure 5). Use copious amounts of cutting fluid such as CF-2 Cutting Fluid from Park Tool. Rotate reamer the correct direction and apply pressure. It will take some work to remove old threads and allow successful tapping up to the 5/8″ size.

Cut slowly and stop often to apply more cutting fluid. Pass the tap completely through the arm, do not reverse the tap back up the thread (figure 6).

Clean all chips from tap and arm. Clean threads in arm using acetone or alcohol. Arm is now ready for bushing.

Select correct bushing. Use a pedal to act as an installation tool (figure 7). Apply a strong thread locker to outside of bushing. Apply a strong thread locker to outside of bushing.

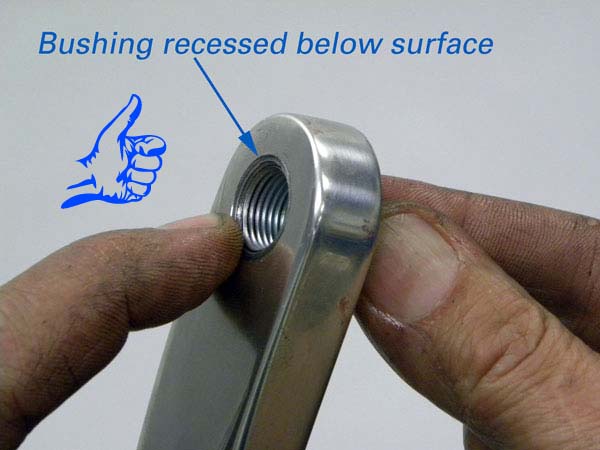

Thread bushing into arm (figure 8). Remove pedal from bushing immediately and fine tune bushing positioning.

It is important the bushing be correctly adjusted in the arm (figure 9). The head of the pedal shaft must press against the crank surface. The bushing must not stick past the outside surface of the crank. The bushing should be slightly recessed.

Continue to rotate bushing until no bushing shows on outer face (figure 10). The head of the pedal axle must press on the crank outer face, just as with normal cranks. The pedal threads pull against the bushing, which transfers the load to the 5/8″ threads in the aluminum arm.

The bushings are typically longer than the thickness of the crank. The excess bushing width will stick out on the crank inner face (figure 11). It is typically best to simply leave this excess. However always check for any interference on the bike. It is possible to power sand or grind the bushing a little shorter. However, work with care as it is difficult to do cleanly and not mar the crank.

Allow thread locker to set up and dry before greasing and installing the pedals. This will take several hours.