How A Rear Derailleur Works

In order to service and fine-tune the rear derailleur, we must first understand how it works. This article helps give a basic understanding of how rear derailleurs work to aid you as you work on servicing your own rear derailleur.

Derailleur Mechanics

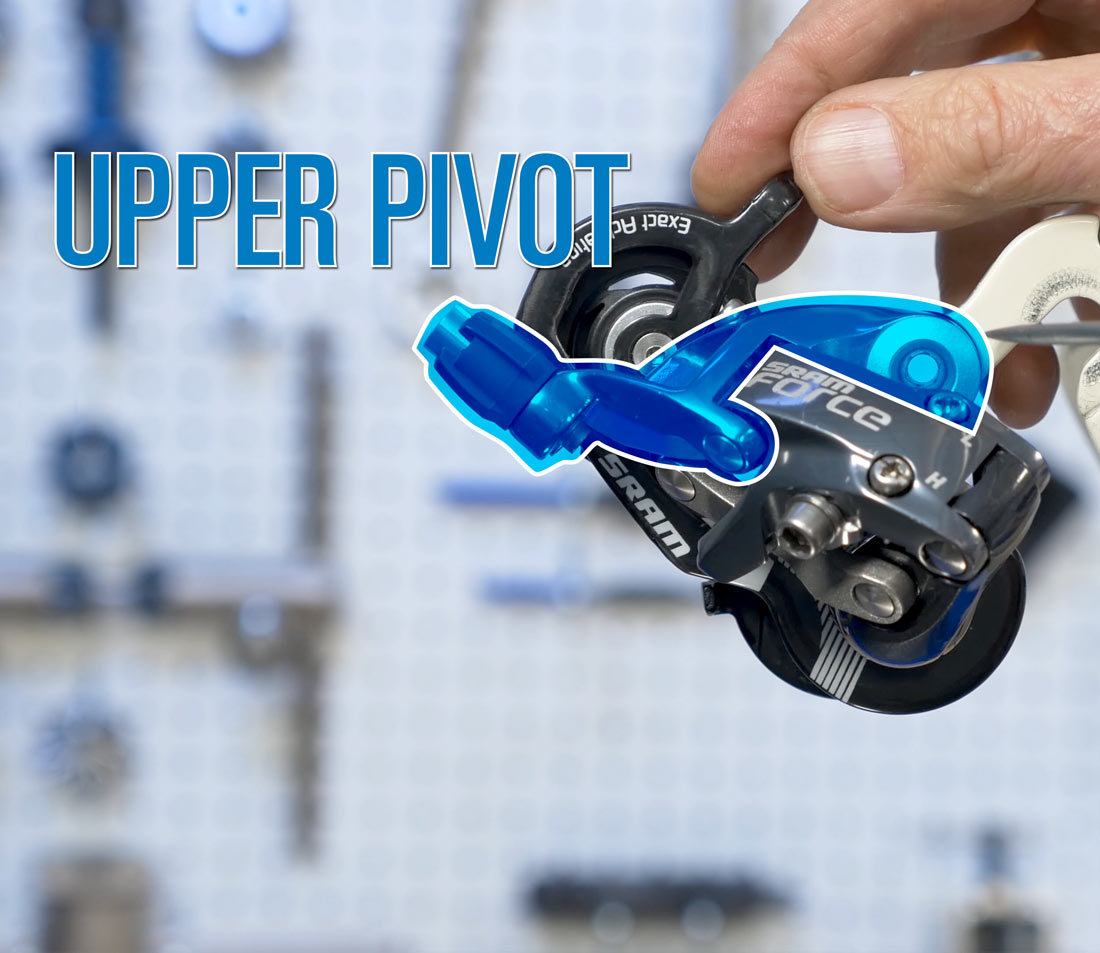

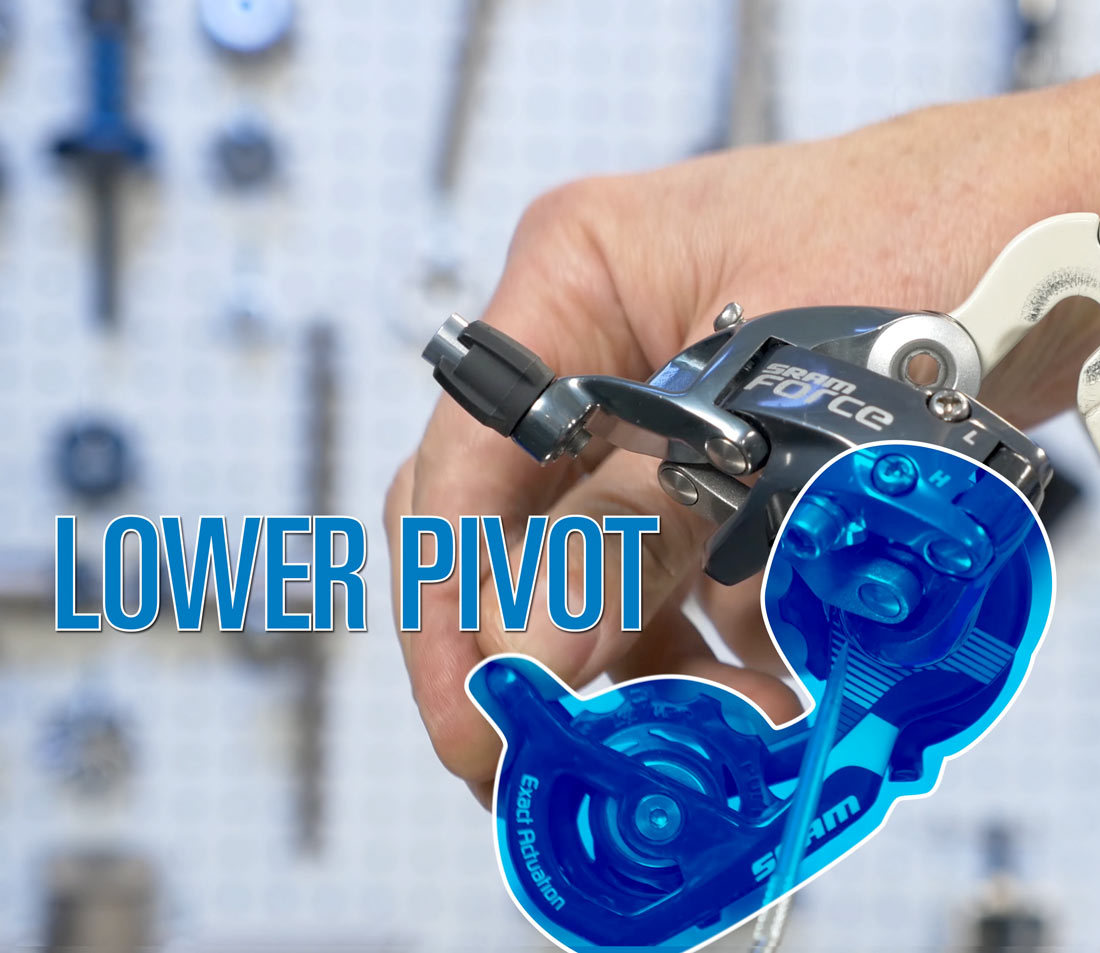

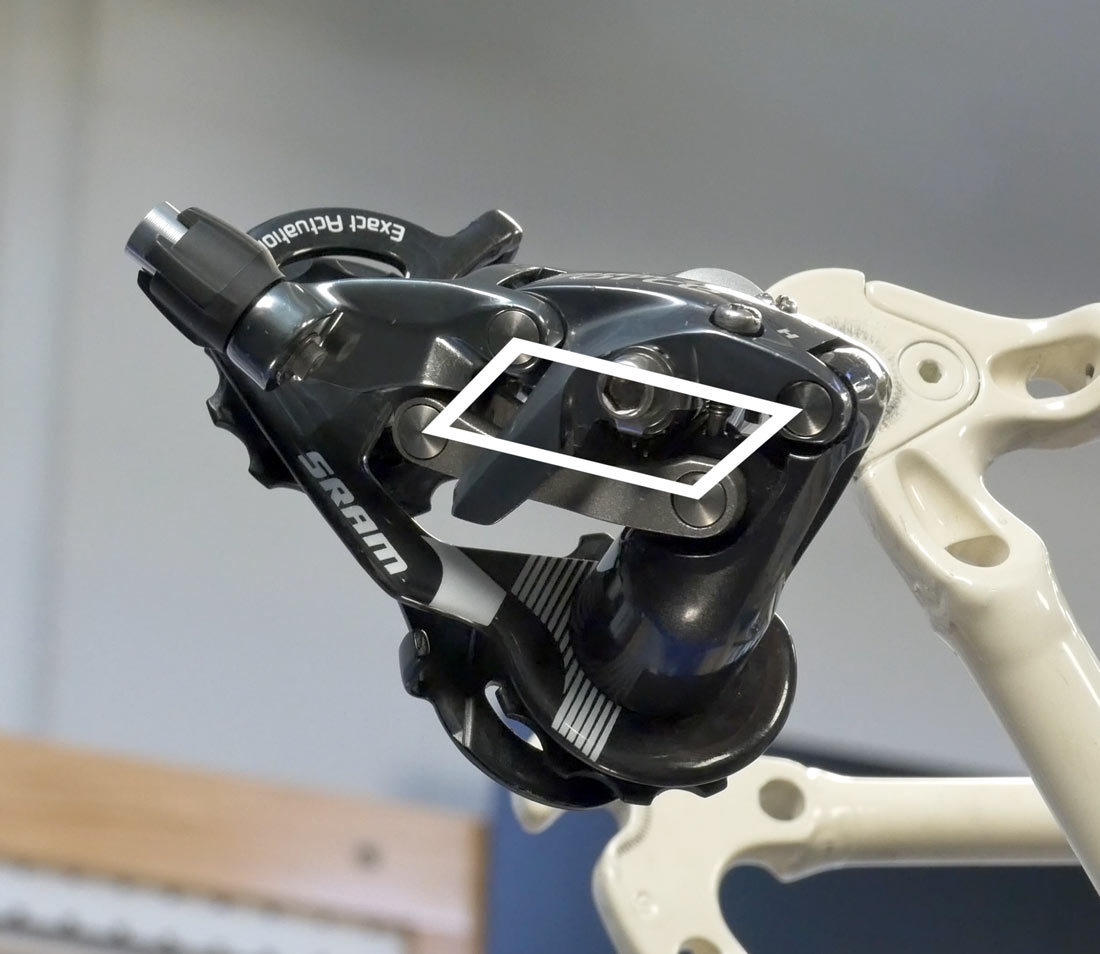

The rear derailleur is the mechanism that shifts the chain at the rear sprockets. There are many different models but they all share the same basic design and functionality. Derailleurs are secured to the bike with a mounting bolt to the frame’s derailleur hanger. The upper pivot to the derailleur is connected to the lower pivot by a linkage system that forms a parallelogram (0:52).

Derailleur upper pivot

Derailleur lower pivot

Rear derailleurs use a cage fitted with two pulleys. The lower pulley pulls backwards to give tension to the lower section of chain. It is called the tension pulley, or ‘T’ pulley for short. The upper pulley guides the chain to the sprockets. It is called the guide pulley, or ‘G’ pulley for short.

On mechanical-type derailleurs, a cable is secured at a pinch bolt. The cable is pulled to move the cage inward. A return spring in the linkage will move the derailleur the opposite direction when the cable is released. Electrical systems use an electrical signal to trigger a motor to move the linkage.

Derailleur cable secured by pinch bolt

Wound spring in derailleur linkage

Indexing

The derailleur is connected to a shift lever with a cable passing through housing. Bikes commonly use an index shifter that moves the cable a small predetermined amount with each click. Barrel adjusters can be located at the derailleur body or the shift lever. They are used to correctly adjust the shifting between cogs. Unthreading, or turning the barrel adjuster counter-clockwise at the shifter or derailleur takes up cable slack, or effectively shortens the housing. This will move the G-pulley slightly inward. Turning the barrel adjuster clockwise will give the cable more slack, effectively lengthening the housing. This moves the G-pulley slightly outward.

Limit Screws

Derailleurs are fitted with limit screws which are adjusted to stop the derailleur from shifting too far inward or too far outward. The end of the limit screw strikes the linkage, and this stops pulley travel (2:51). The ‘L’ screw determines the limit of innermost cage travel. Tightening the L-screw will restrict travel on the left side. The ‘H’ screw determines the limit of outermost cage travel. Tightening the ‘H’ limit screw will restrict travel on the right side.

It is common to find another adjustment screw on the derailleur body called the ‘B’ screw. This screw controls the size of the gap between the guide pulley and sprockets. Tightening the B-screw will increase the size of this gap while loosening the B-screw will shrink this gap.

And those are the basics of the rear derailleur.