How A Front Derailleur Works

In order to service and fine-tune the front derailleur, we need to understand how it works. This article helps give a basic understanding of how front derailleurs work to aid you as you work on servicing your own front derailleur.

Derailleur Attachment

The front derailleur is the mechanism that shifts the chain on bike with more than one front chainring. There are many different makes and models, but they all share the same basic design and functionality. Front derailleurs are attached to the bike with either a clamp or bracket.

Clamp mounted derailleur

Bracket mounted derailleur

Derailleur Mechanics

The derailleur has a cage that forms a box around the chain. The cage is attached to a linkage system called the parallelogram, similar to a rear derailleur. For mechanical-type derailleurs, the linkage is held and moved by a cable. A wound spring in the linkage moves the cage in the opposite direction when the cable is released. An electric derailleur uses a small motor to move the cage.

Linkage system on a front derailleur, called a parallelogram

Wound spring inside mechanical front derailleur

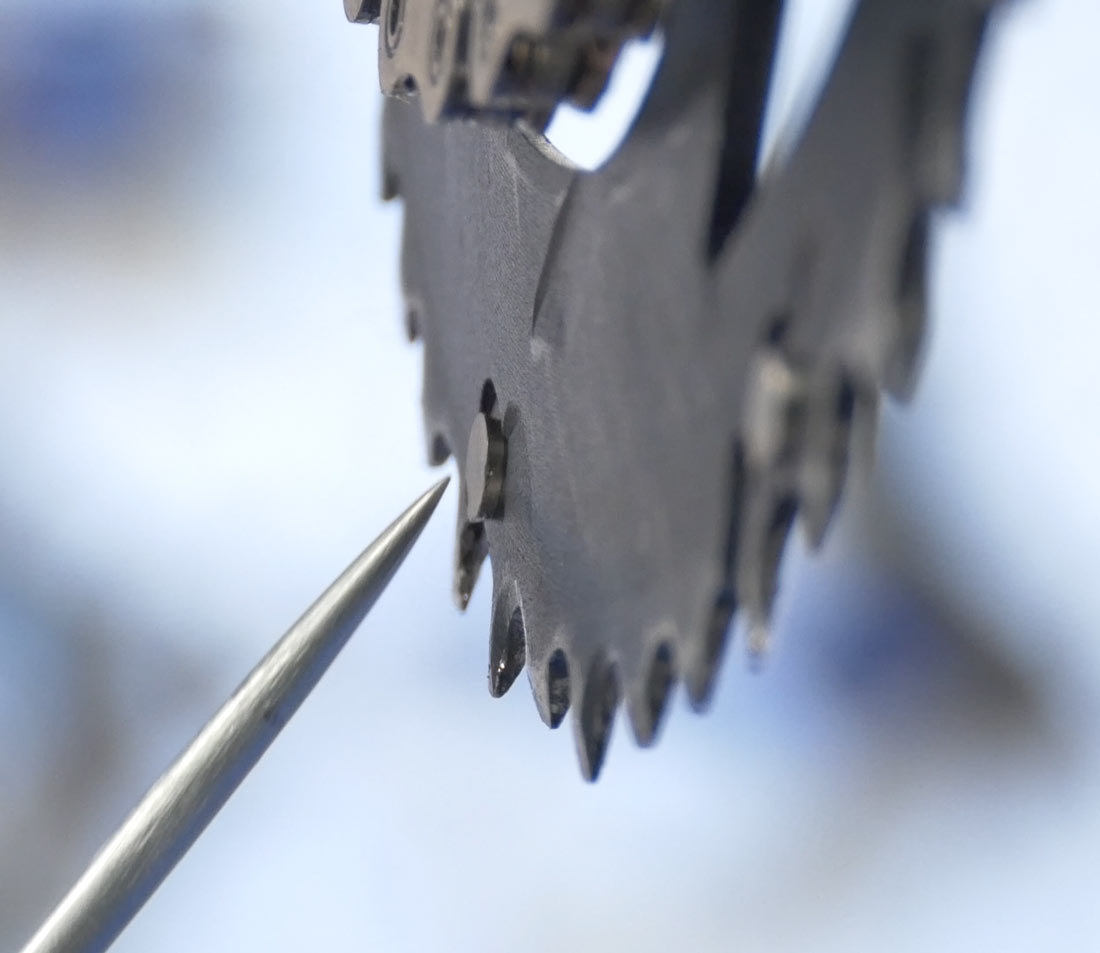

Shifting only occurs if the rider is pedaling. When shifting outward, the chain is flexed to the right and begins to rise up from the pedaling action. Modern chainrings are designed with shift ramps and features to help pick up the chain as it moves outward. Inward shifts occur in a similar manner. The cage pushes the chain from behind, where it is engaged on the ring. The cage continues to push inward until the chain begins to fall off the larger ring. The smaller ring catches and engages the chain.

Limit Screws

Like a rear derailleur, the front derailleur will have limit screws marked ‘H’ and ‘L’. These screws are used to stop the cage at the extreme ends of travel. The end of the limit screw strikes the linkage, and this stops cage travel. The ‘L’ screws determines the amount of innermost cage travel. Tightening the ‘L’ screw will restrict the limit on the left side. The ‘H’ screw determines the outermost cage travel. Tightening the ‘H’ screw will restrict the limit on the right side.

Front derailleur H and L limit screws

Limit screw striking linkage

Height & Rotation

Some derailleur designs allow for adjustment to the height of the cage. The outer cage should clear the largest chainring by 2 to 3 millimeters. Another adjustment for certain designs is cage rotation. Generally, the cage is set parallel to the rings. However, direct-mount systems do not allow for rotation.

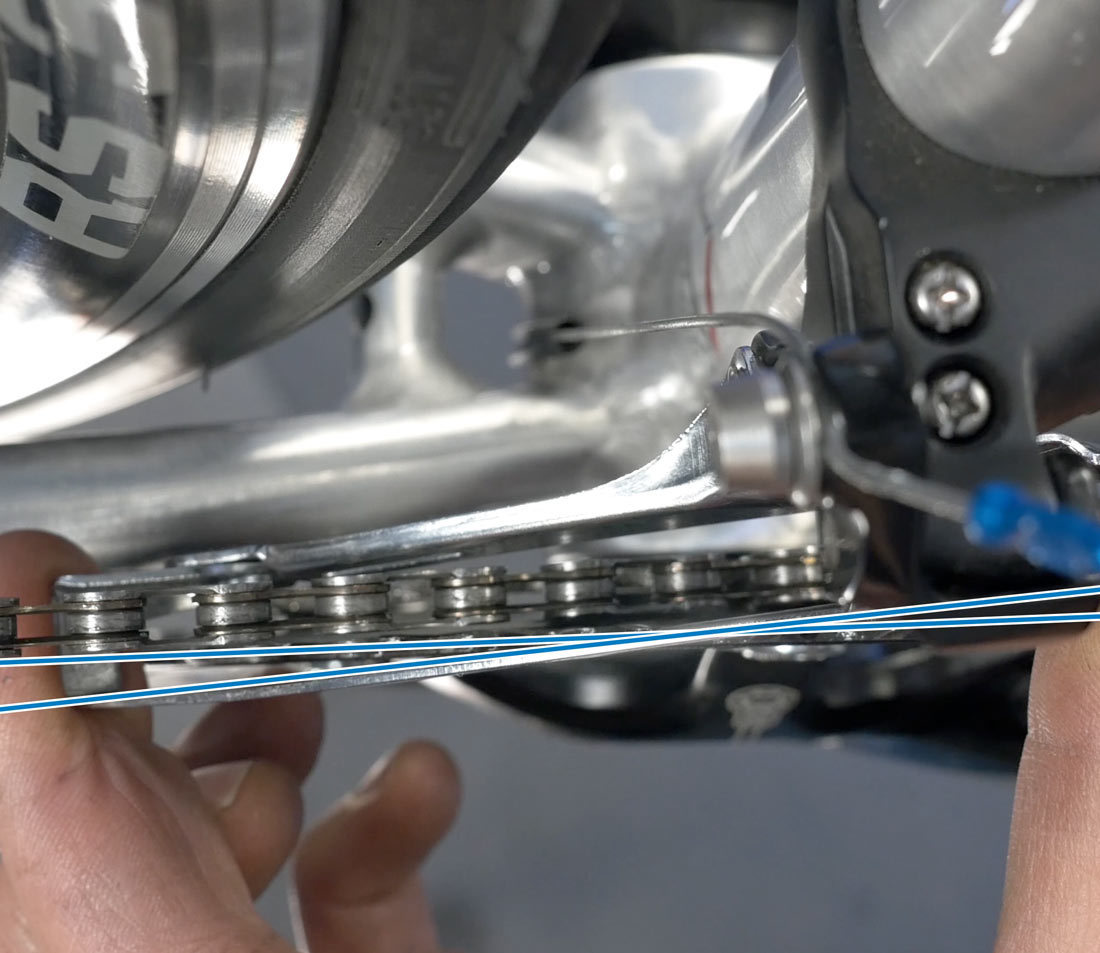

Poor derailleur rotation

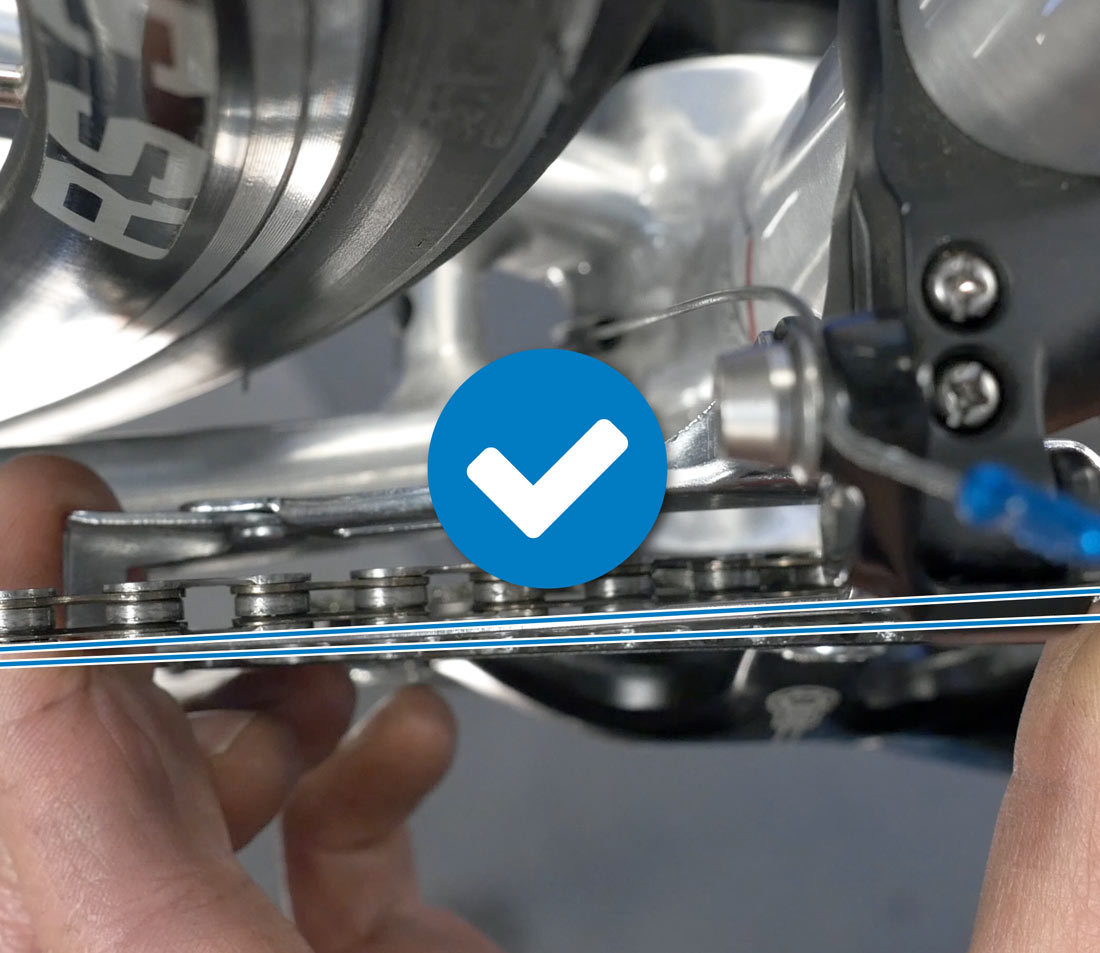

Correct derailleur rotation

Indexing

Front shifting systems can use indexing similar to the rear derailleur. The movement of the cage is correlated to the movement of the cable. Shift levers designed for indexing move the cable in small pre-determined increments. Similar to the rear derailleur, a barrel adjuster is used to control the cable length. Turning the barrel adjuster counter-clockwise effectively shortens the housing, moving the cage to the right. Turning the barrel adjuster clockwise effectively lengthens the housing, moving the cage to the left.

These are the basics of the front derailleur.