Brake Bleeding for SRAM® Bleeding Edge Hydraulic Brakes

This article will review the bleeding procedure for SRAM® hydraulic brakes with Bleeding Edge, while using the Park Tool BKD-1.2 or BKD-1 Bleed Kit.

Preliminary Info

- BKD-1.2 Hydraulic Brake Bleed Kit (DOT)

- PP-1.2 Hydraulic Brake Piston Press

- Hex & Torx®-Compatible Wrenches

- NP-6 Needle Nose Pliers

- Zip ties

- Torque wrench

- Isopropyl alcohol

- Rags

This bleeding procedure will work on SRAM drop bar and flat bar brakes that feature Bleeding Edge. See this article for the non-Bleeding Edge procedure.

Brake bleeding is considered an advanced service procedure, and requires a thorough technical knowledge of the braking system. If in doubt, or if this procedure is not working, contact the brake manufacturer for model-specific information.

It is important to always use the appropriate brake fluid for the brake being serviced. Never use mineral oil in brakes designed for DOT brake fluid, or vice versa. Never share bleed kits between DOT fluid and mineral oil systems. Mixing fluids can cause damage to components and lead to brake failure, which is dangerous.

DOT fluid is corrosive, and it can irritate the skin and eyes, and damage paint and other finishes - so it is important to take care. Wear gloves and eye protection during this procedure. Have plenty of rags handy for wiping up spills as quick as possible. Isopropyl alchohol is a good cleaner to help clean and neutralize the DOT fluid, if spilled. You may want to also cover your work area to avoid getting fluid on the floor.Dispose of any spent fluid in accordance with your local waste disposal authorities

Bicycle Prep

- Install the bike in a repair stand if available.

- Begin by prepping the lever.

Flat Bars:

- If your flat bar lever is equipped with a contact adjuster, turn it opposite the arrow until it stops.

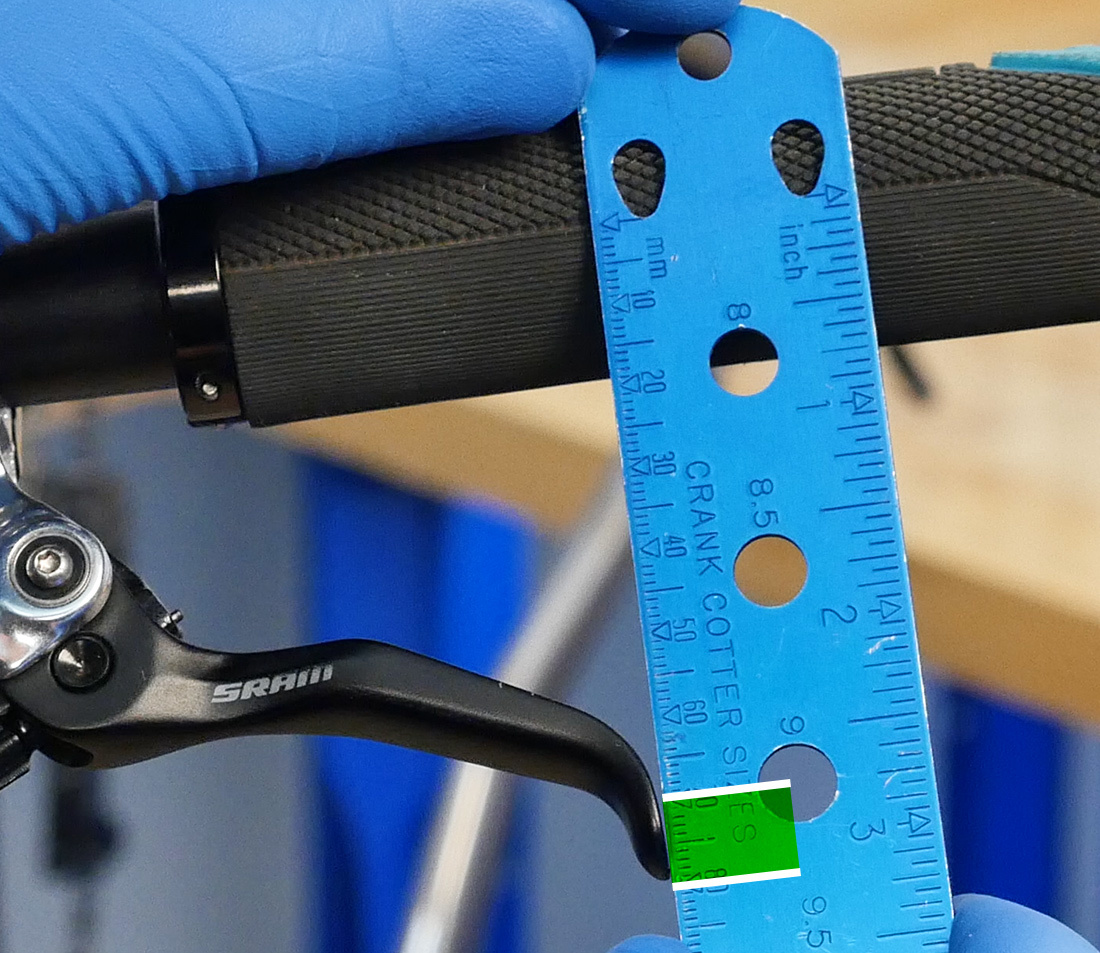

- Measure the amount of reach from the centerline of the handlebar to the tip of the brake lever. To bleed it needs to be between 75mm and 80mm. if not, make note of your current adjustment and then adjust to between 75mm and 80mm. On some models, this is a tool-free adjustment, while other models require a hex wrench.

Turn contact adjuster until clicking stops

Tip of lever should fall between 75-80mm from center of handlebar

Drop bars:

- For drop bars with a contact adjustment, pull back the cover and use a 5mm hex to turn the adjustment counter clockwise till it stops.

- Tie a rag around the lever to catch any spills.

- Remove the wheel.

- Use a pad spreader such as the PP-1.2 to push the pads back to allow for the bleed blocks once the pads are removed.

Lever prepped with rag

spread pads to allow for bleed blocks

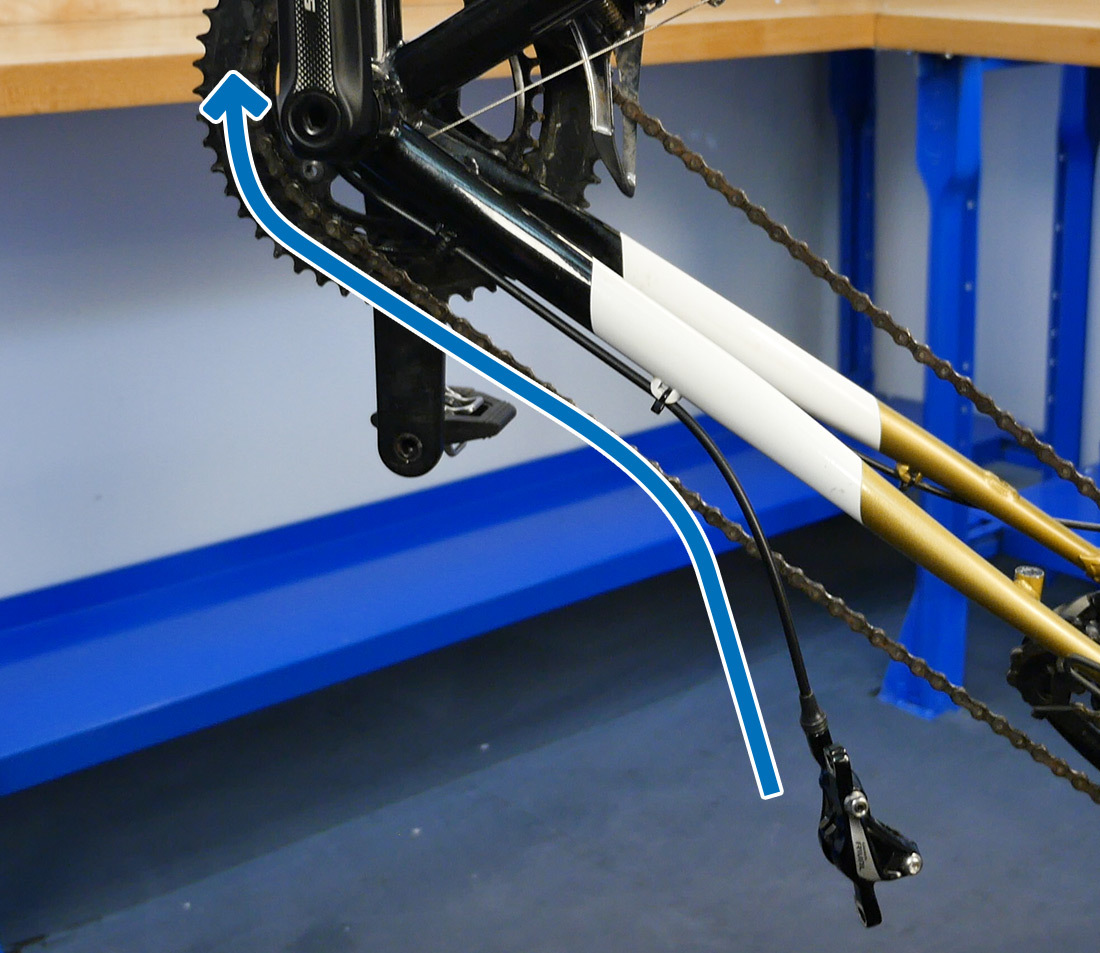

- Angle the bike in the stand so that the path of the hose from the caliper to the lever is consistently traveling upwards. It can also help to remove the caliper and let it hang, especially for rear calipers. This makes the path for air bubbles as easy as possible to follow.

- The pads are removed to prevent any contamination.

- Remove the pad pin clip with a needlenose pliers, and unthread the pad pin with a 2.5mm hex wrench.

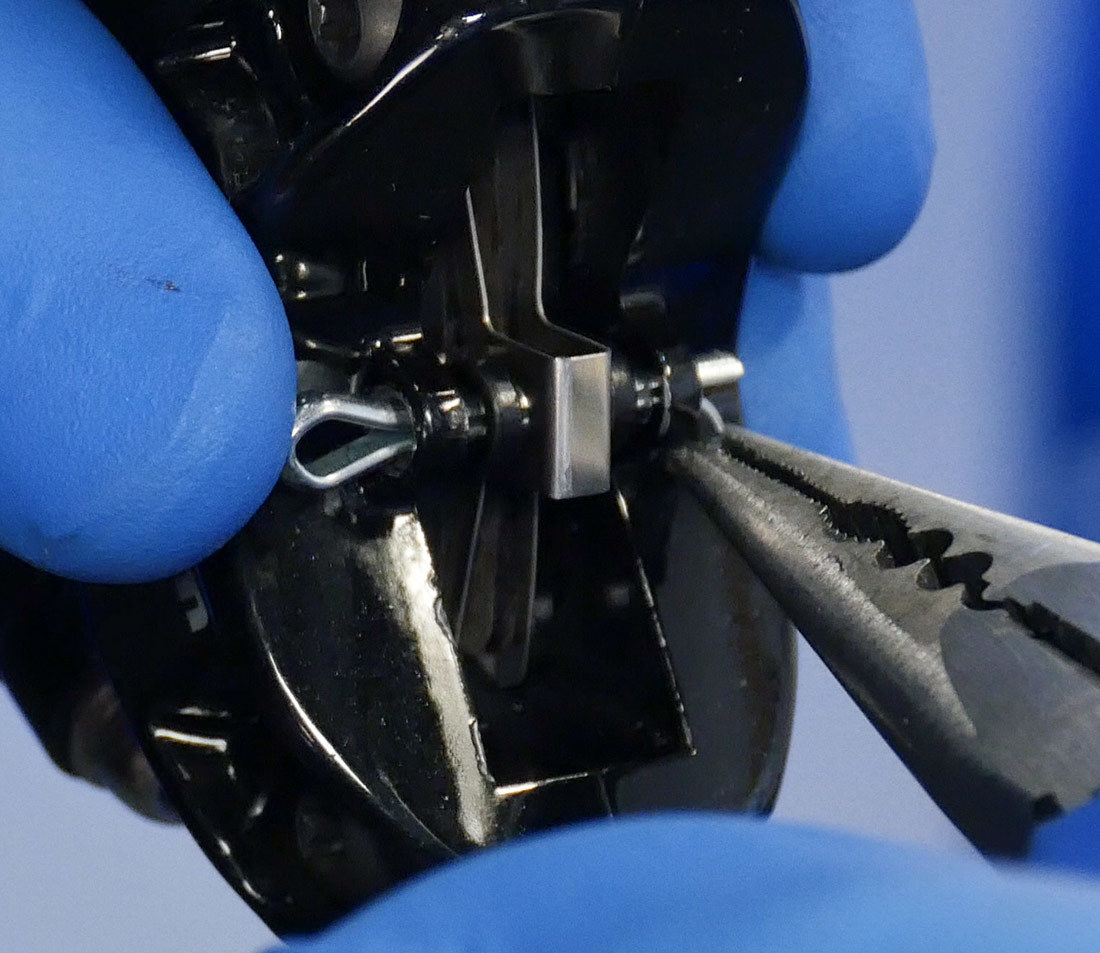

- For pads with a split cotter pin, use a needlenose pliers to straighten the pin, then pull it out.

threaded pad pin: remove clip and unthread pin

cotter pin: bend pin straight and remove

- Pull the pads out. It can help to push from the bottom initially.

- install the bleed block and secure with either the pad pin, a rubber band or a zip tie.

- If the caliper has two sets of pistons, use both bleed blocks.

Remove pads by hand

Caliper with two sets of pistons

- Attach the syringe holder above the caliper.

Bleed Kit Prep

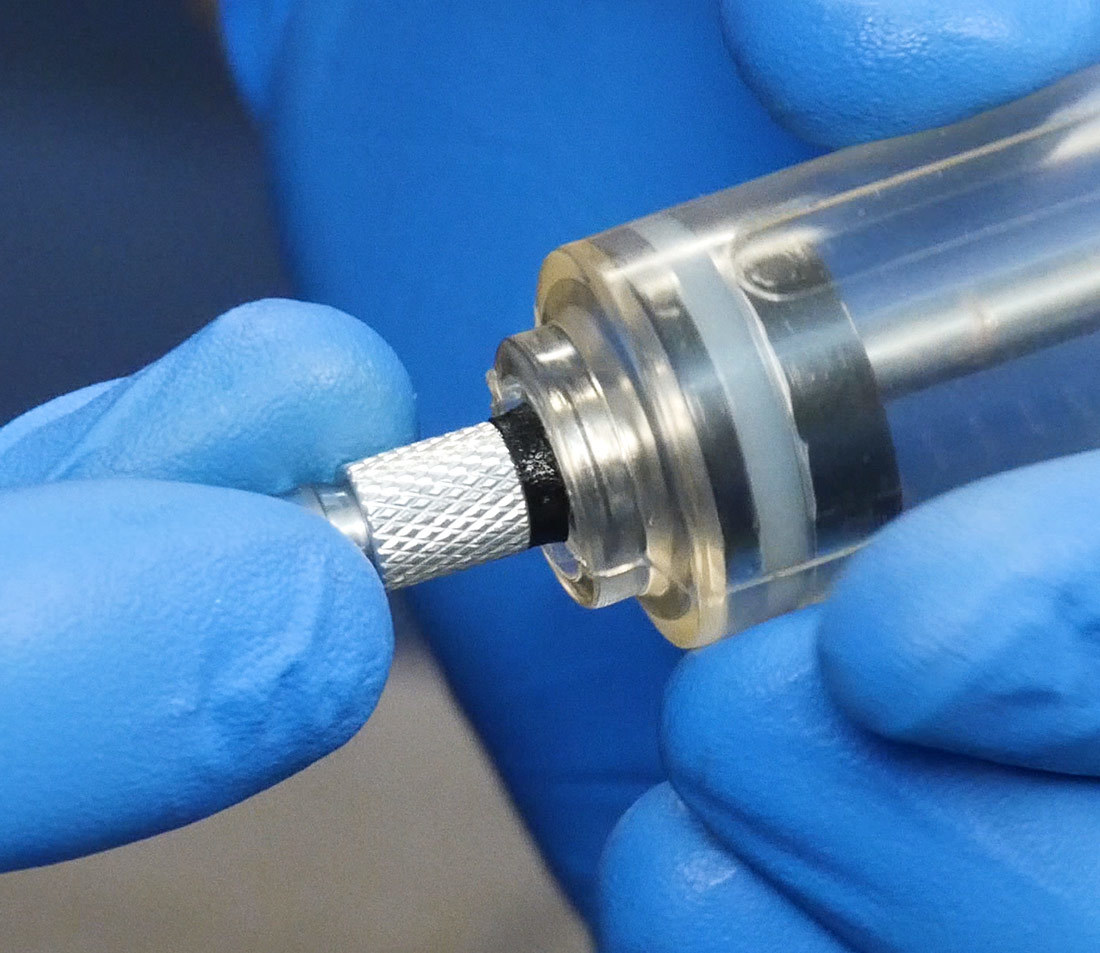

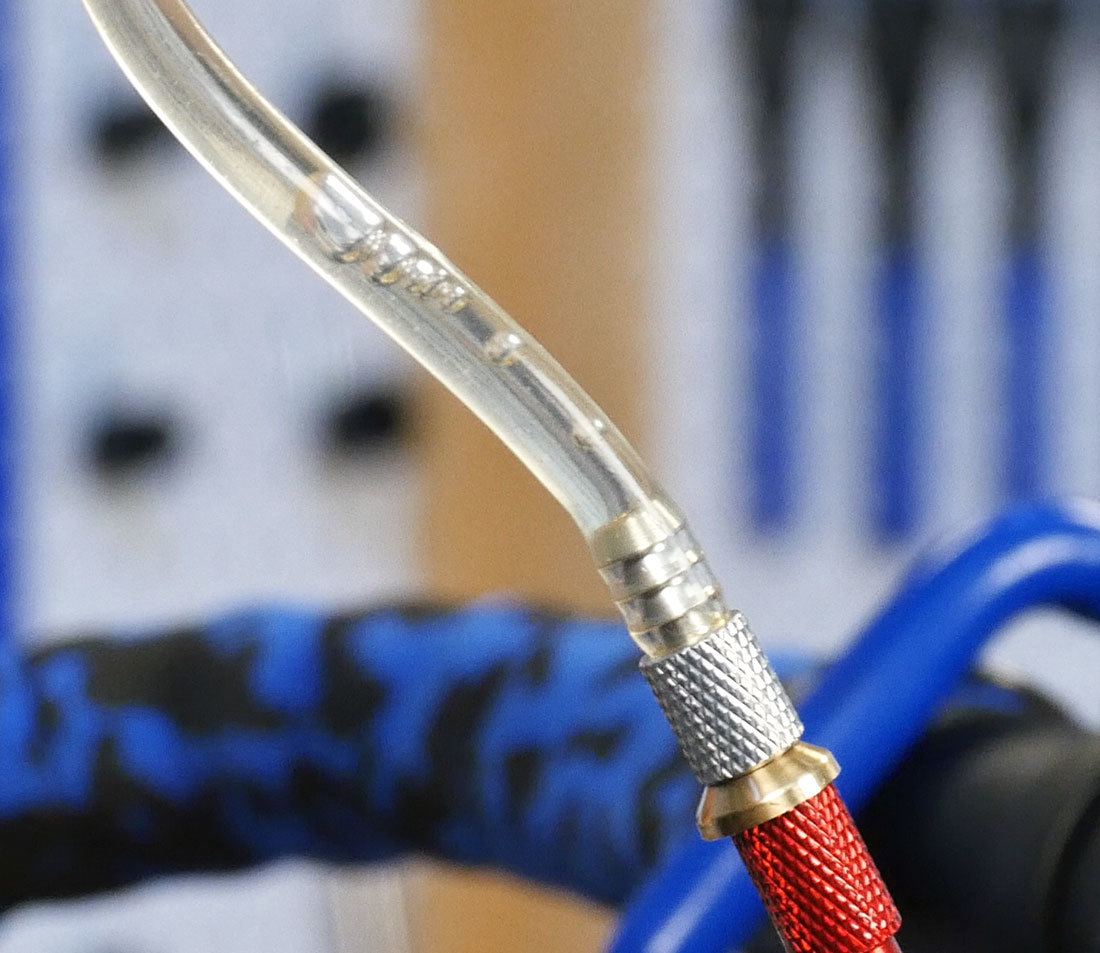

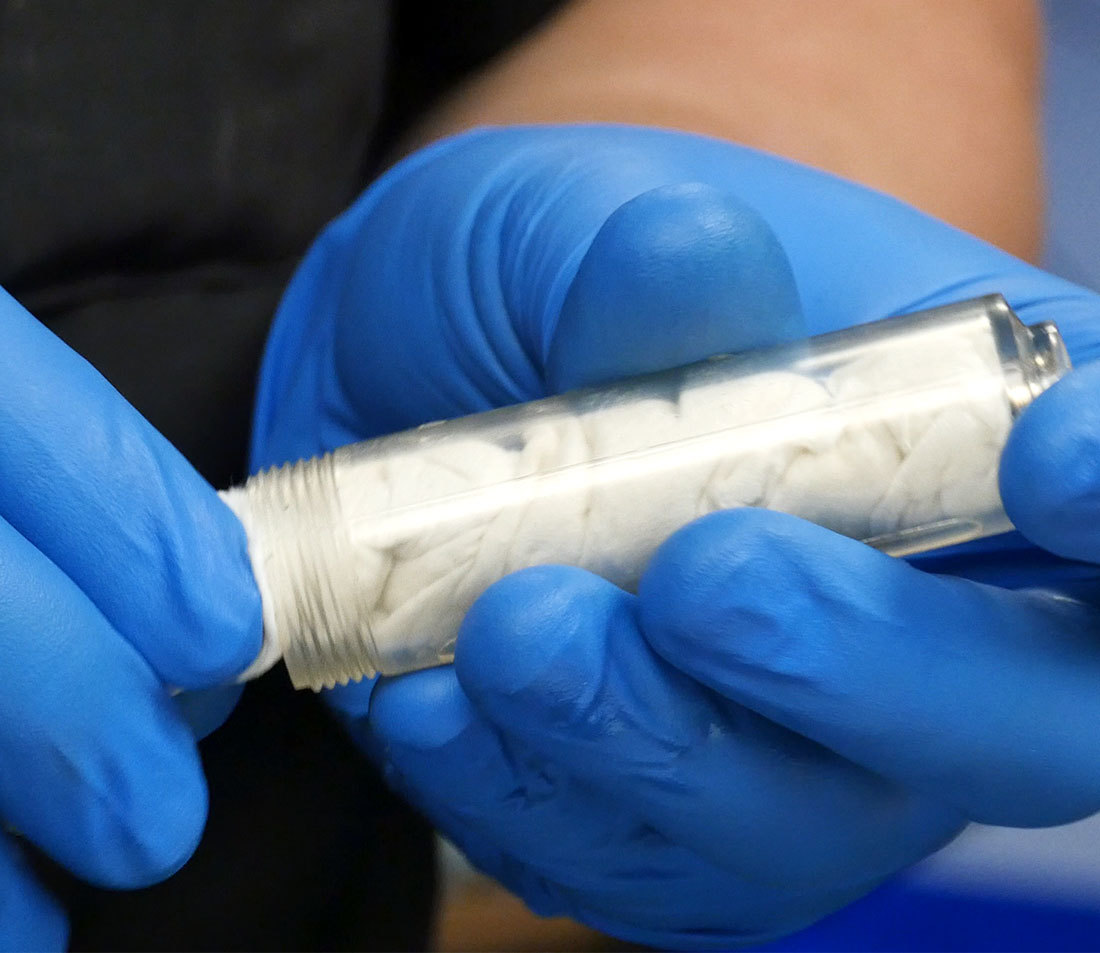

- Install the double ended hoses onto the syringes, with the o ring capture away from the syringe.

- Install the red adaptor end (part #2618) onto one syringe hose.

Thread double-ended hoses into syringes

Thread adaptor #2618 onto first hose

- This will be the lever syringe. Fill it to 1/2-3/4 full.

- Hold the hose end up and push the syringe. Eliminate as much air as possible. Clip the hose.

Hold syringe upright

push until no air remains in hose

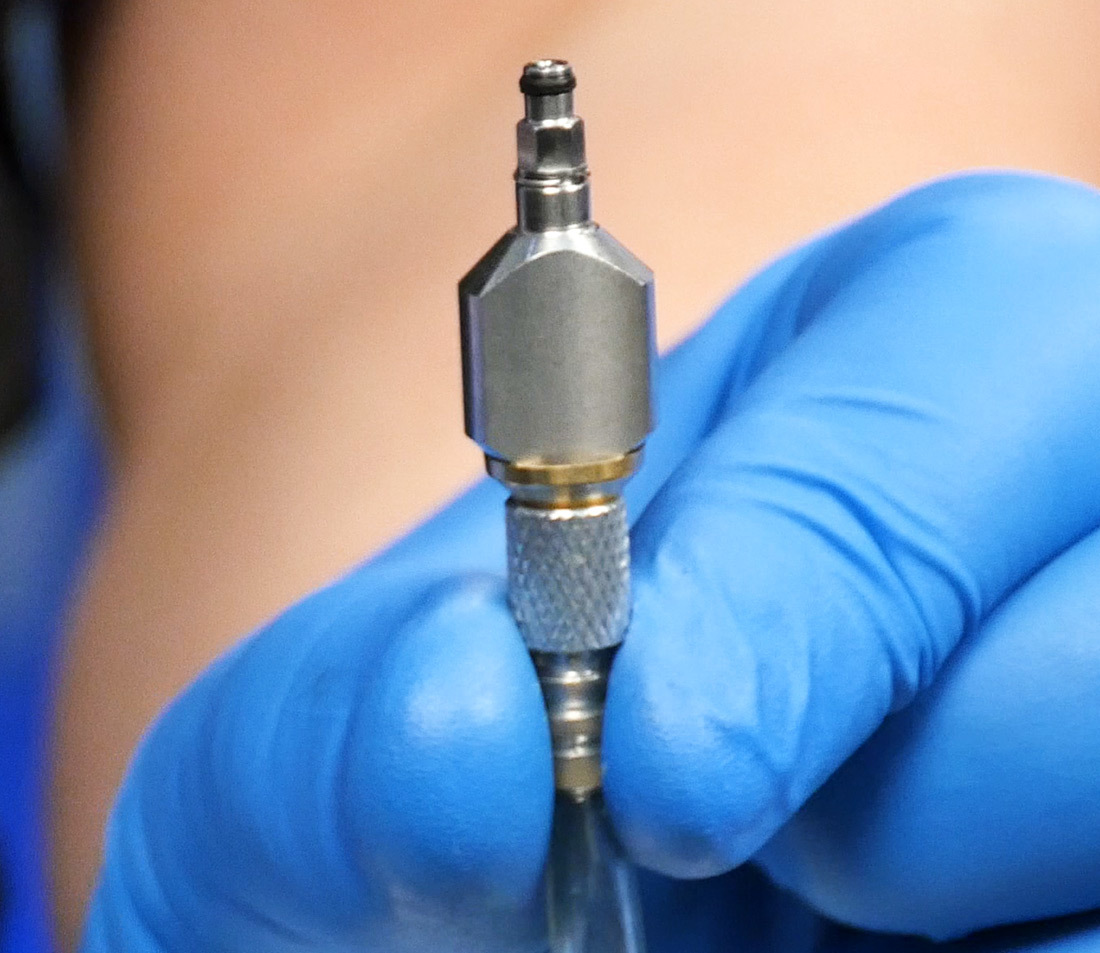

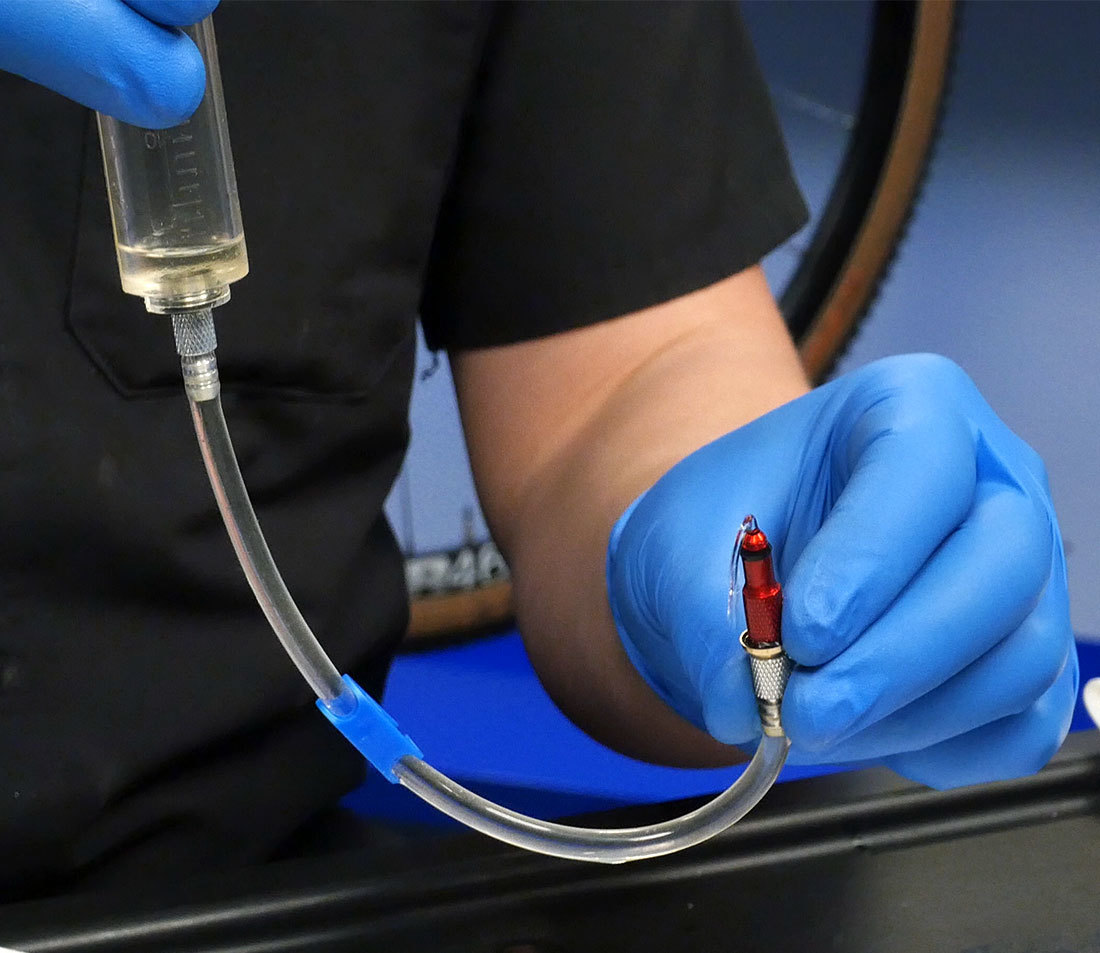

- Install the Bleeding Edge adaptor end (#2612) on the other syringe.

- This will be the caliper syringe. Fill it 1/4 full.

- Repeat the process of eliminating air from the hose and clipping the hose.

- Remove the bleed screw from the lever using a Torx®-compatible T10 wrench. There is an o-ring on this screw - make sure it also comes out.

- Install the 3/4 full syringe into the lever. Ensure the o-ring is seated fully and evenly in the capture of the bleed port as you thread in the adapter. Clean up any spilled fluid right away.

Ensure that o-ring is removed along with bleed screw

Fully thread syringe into bleed port

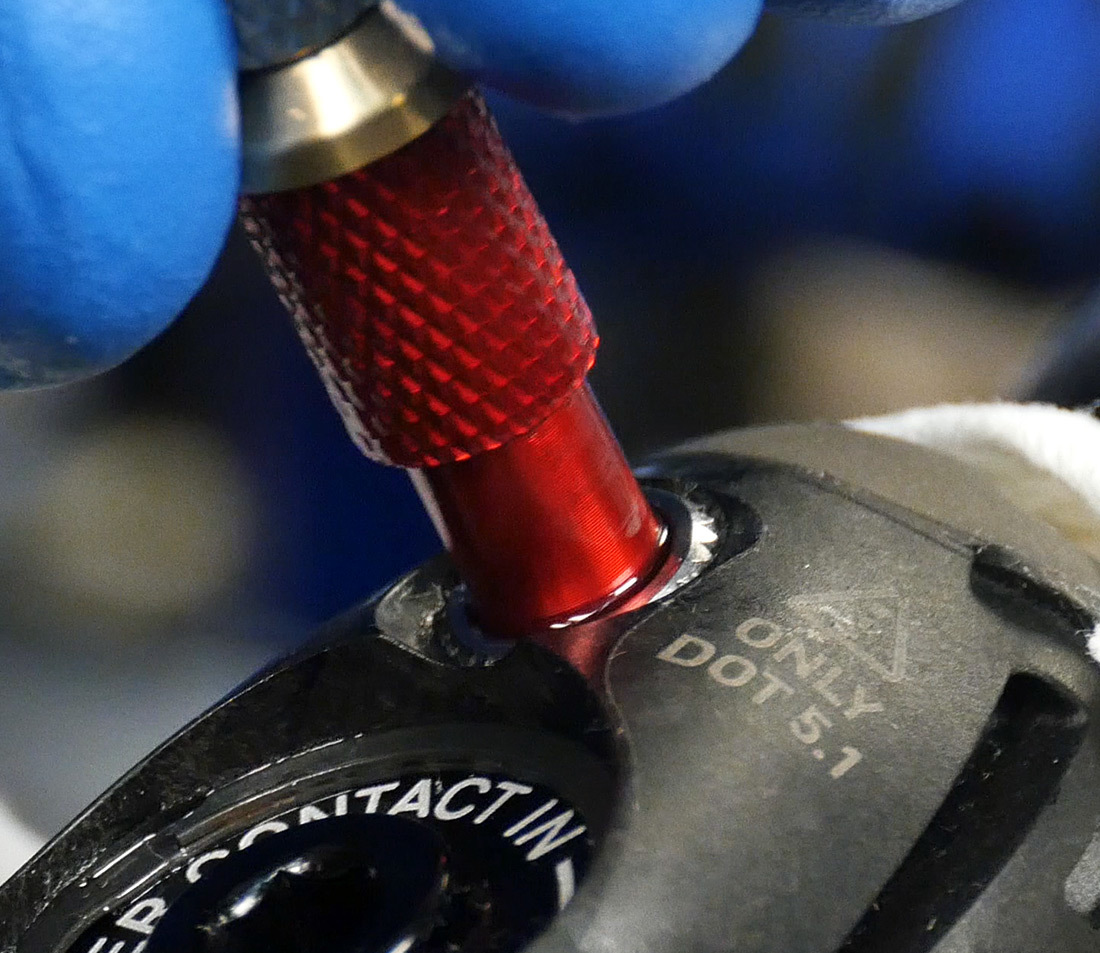

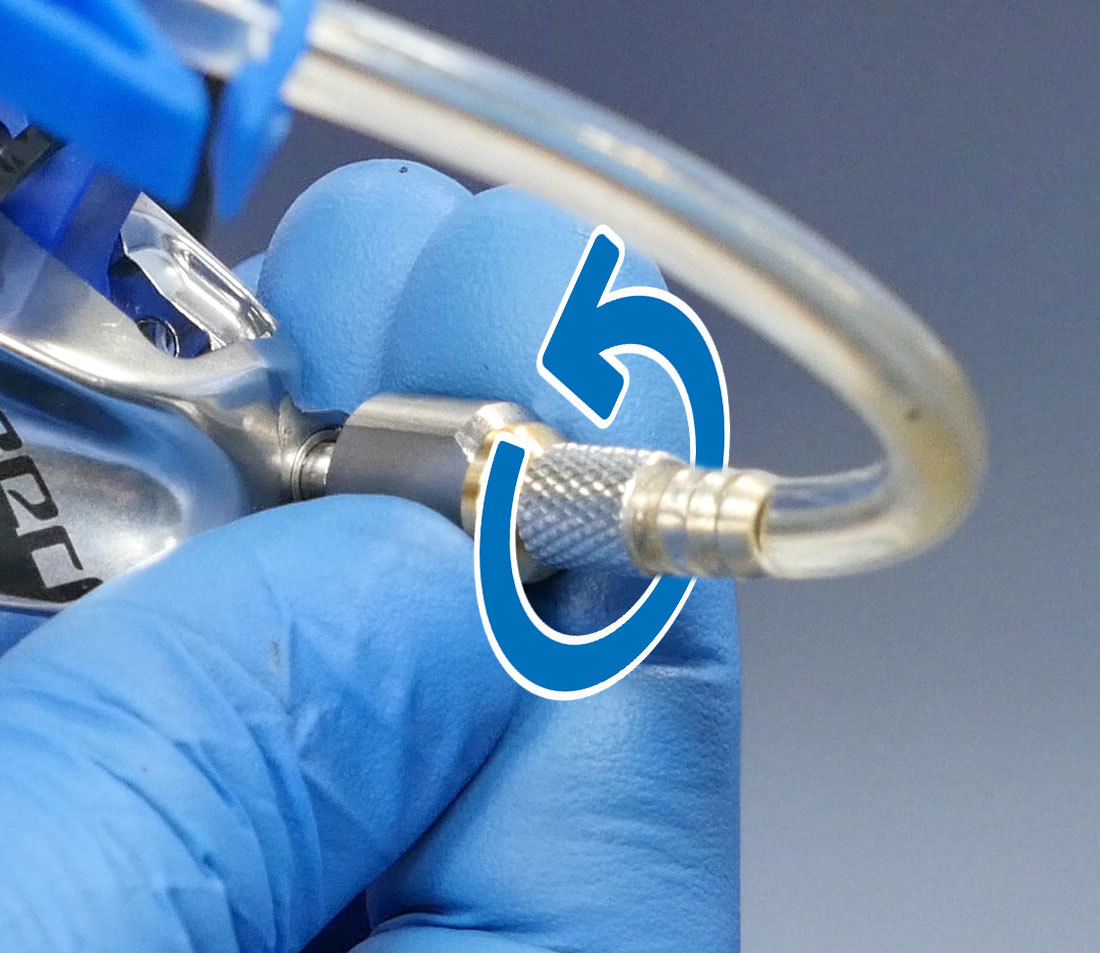

- At the caliper, remove the rubber cap from the bleed port. Use a 4mm hex wrench to loosen the Bleeding Edge port, then snug it back up just slightly.

- Insert the Bleeding Edge adaptor into the caliper. It will snap into place.

Loosen then re-snug Bleeding Edge port

Snap Bleeding Edge adapter into caliper

- Install the caliper syringe into the holder.

Bleeding

- Unclip both syringes.

- Open the Bleeding Edge port by loosening 1 full turn.

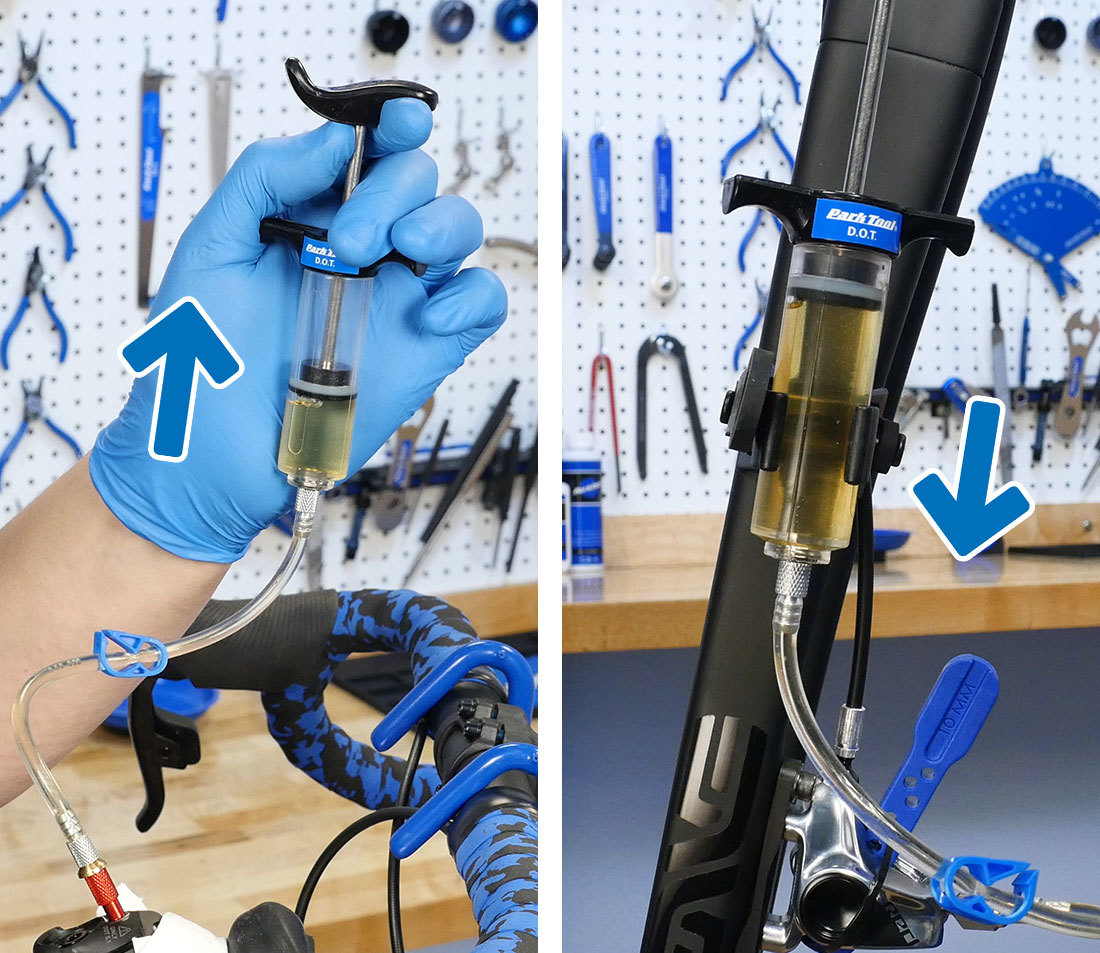

- Push on the lever syringe. Do this until there is about 1/4 a syringe of fluid in the lever syringe and about 3/4 in the lower.

NOTE: If the fluid coming out is dirty or discolored, push all fluid to the lever syringe, remove the syringes, refill and start the bleeding process over. This will ensure that you brake system has clean fresh fluid.

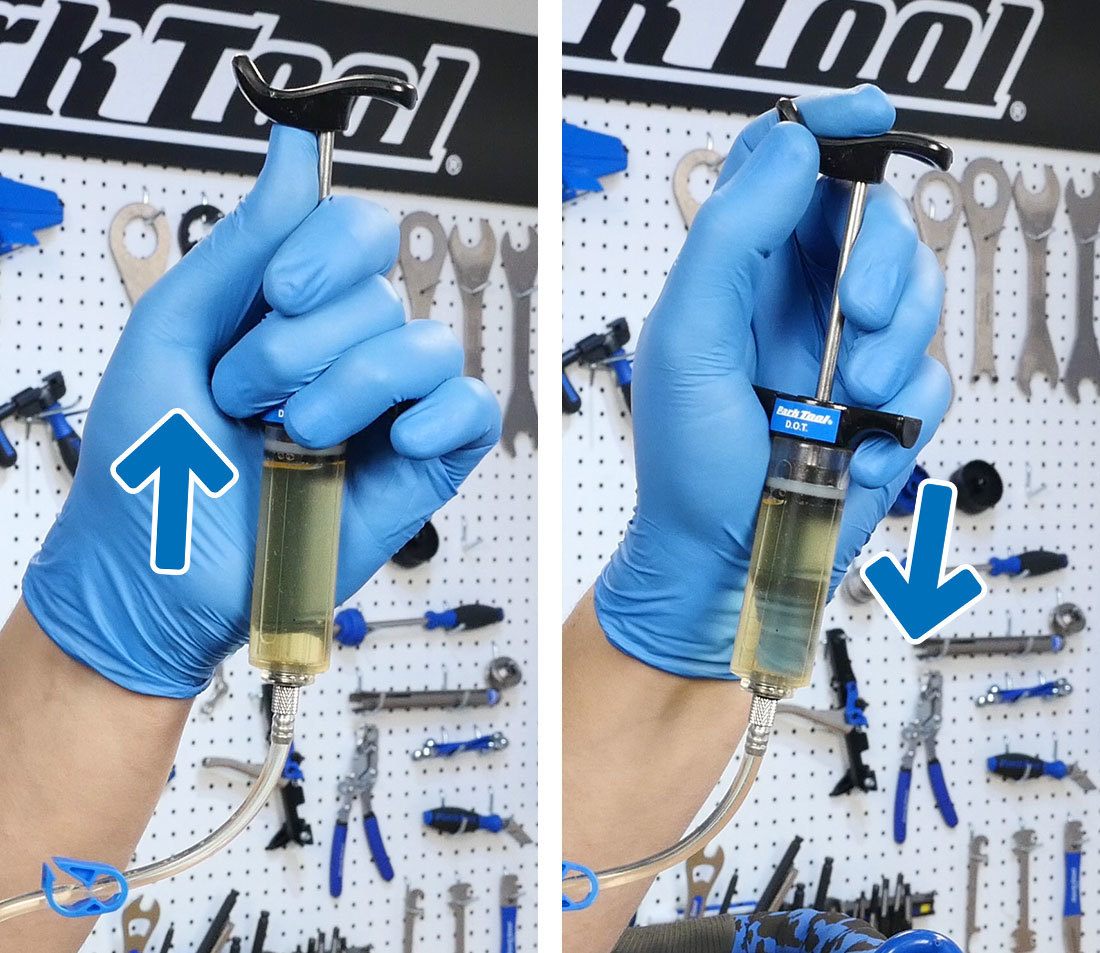

- Use the lever syringe to pull the fluid back up to the lever syringe. The vacuum created will dislodge air bubbles. Be careful not to pull too hard and pull air past the syringes.

Draw fluid back through the system

Bubbles escaping system via lever syringe

- Close the Bleeding Edge port.

- Squeeze the brake lever 3 times.

- Pull back on the lever syringe to create a vacuum, then push on the syringe to create pressure in the system.

- Repeat steps 6-7. Do this procedure till you see no bubbles or very few bubbles escaping via the lever syringe hose.

Fully squeeze lever 3 times

Pull to create suction/push to create pressure

- Push on the syringe one last time to equalize the pressures.

Reset Bicycle

- Clip and remove the lever syringe.

- Install the bleed port screw. Torque to 1.5-1.7 Nm.

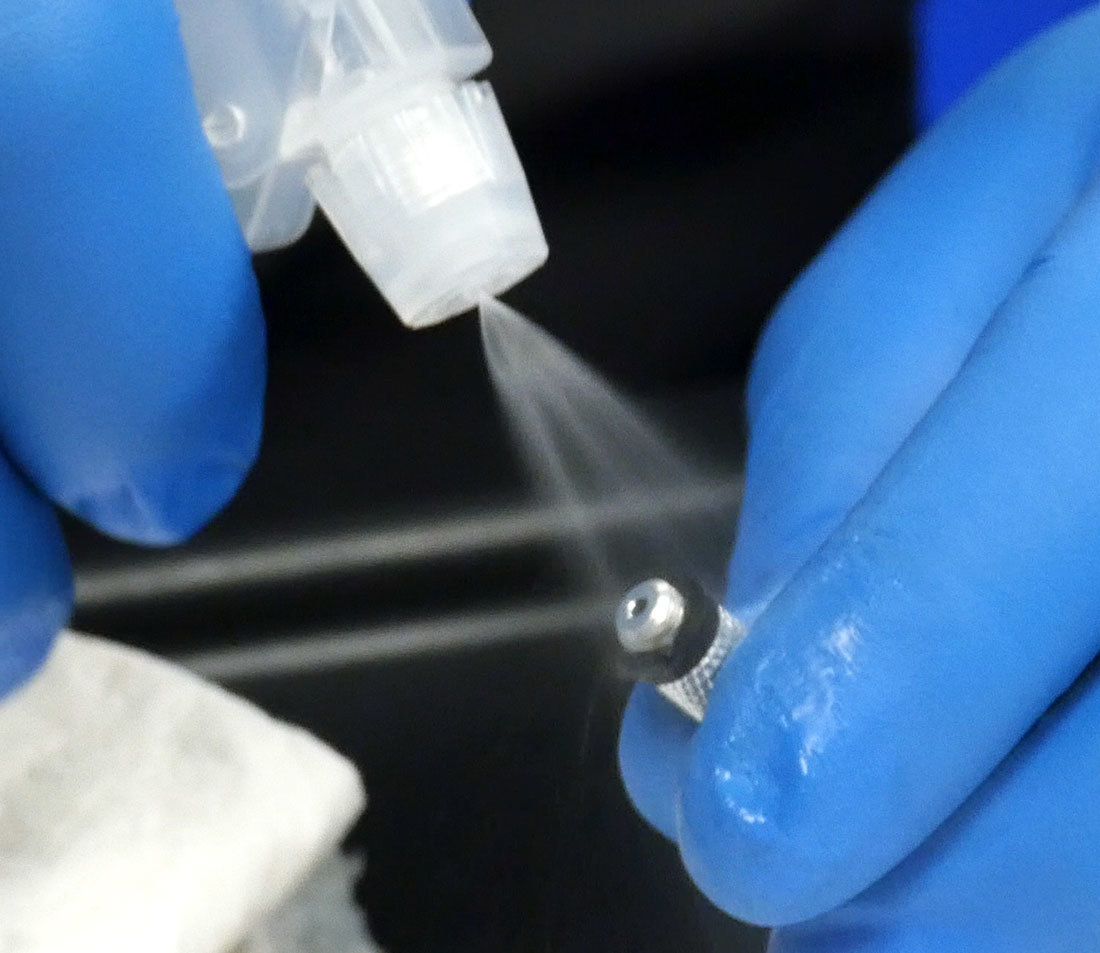

- Clean up any spilled fluid with isopropyl alcohol.

Snug bleed port screw

Clean and wipe all surrounding areas

- Reset the lever reach to users preference

- For drop bars, pull hood back into place.

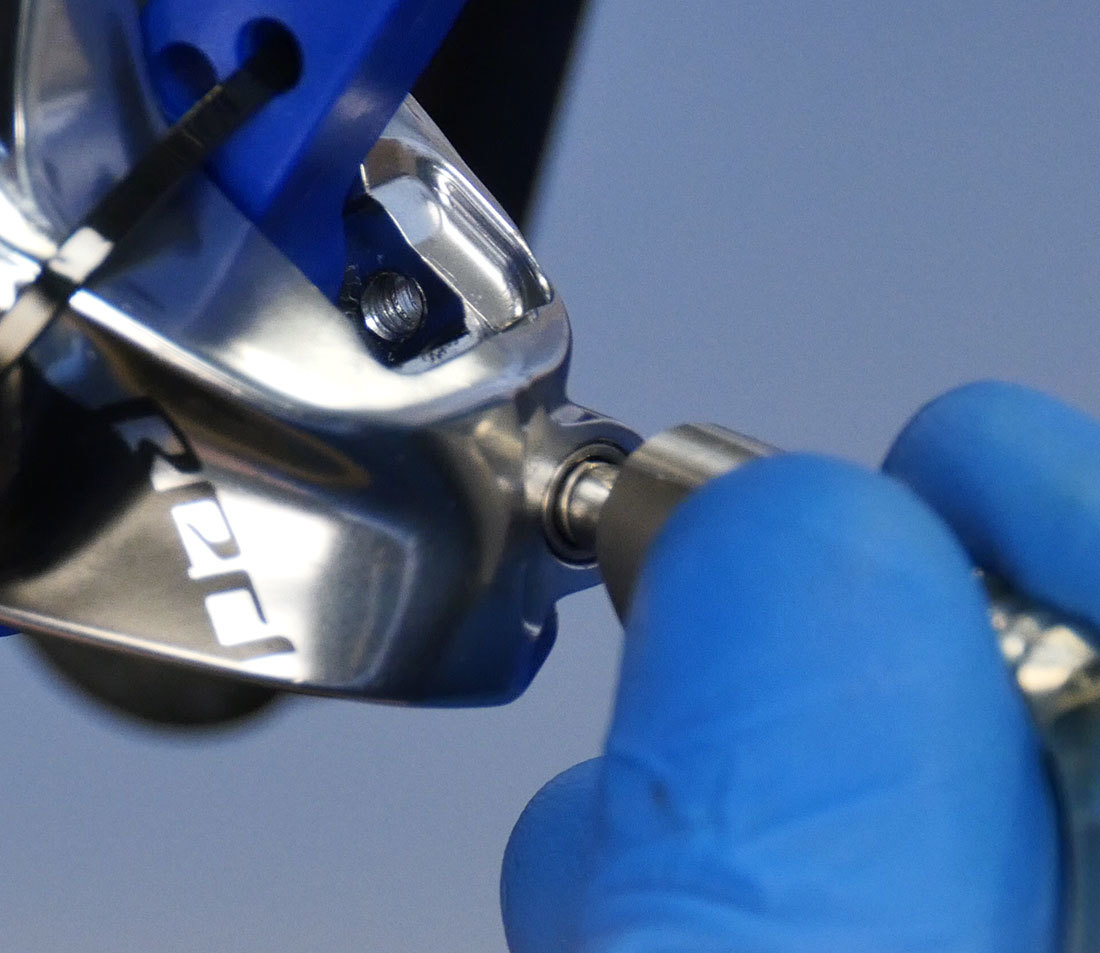

- At the caliper, tighten the Bleeding Edge adapter then pull the adapter off.

- Once the adapter is removed, torque the fitting to 1.5-1.7 Nm with a hex wrench.

- Remove the bleed blocks and clean out the caliper body with alcohol

Snug bleeding edge port

Clean and wipe all surrounding areas

- Reinstall the pads, pad pin and clip.

- Reinstall the wheel.

- Pull the brake lever 3 times to set the pads.

NOTE: If you encounter rubbing, you may need to realign your calipers at this time.

Clean Kit

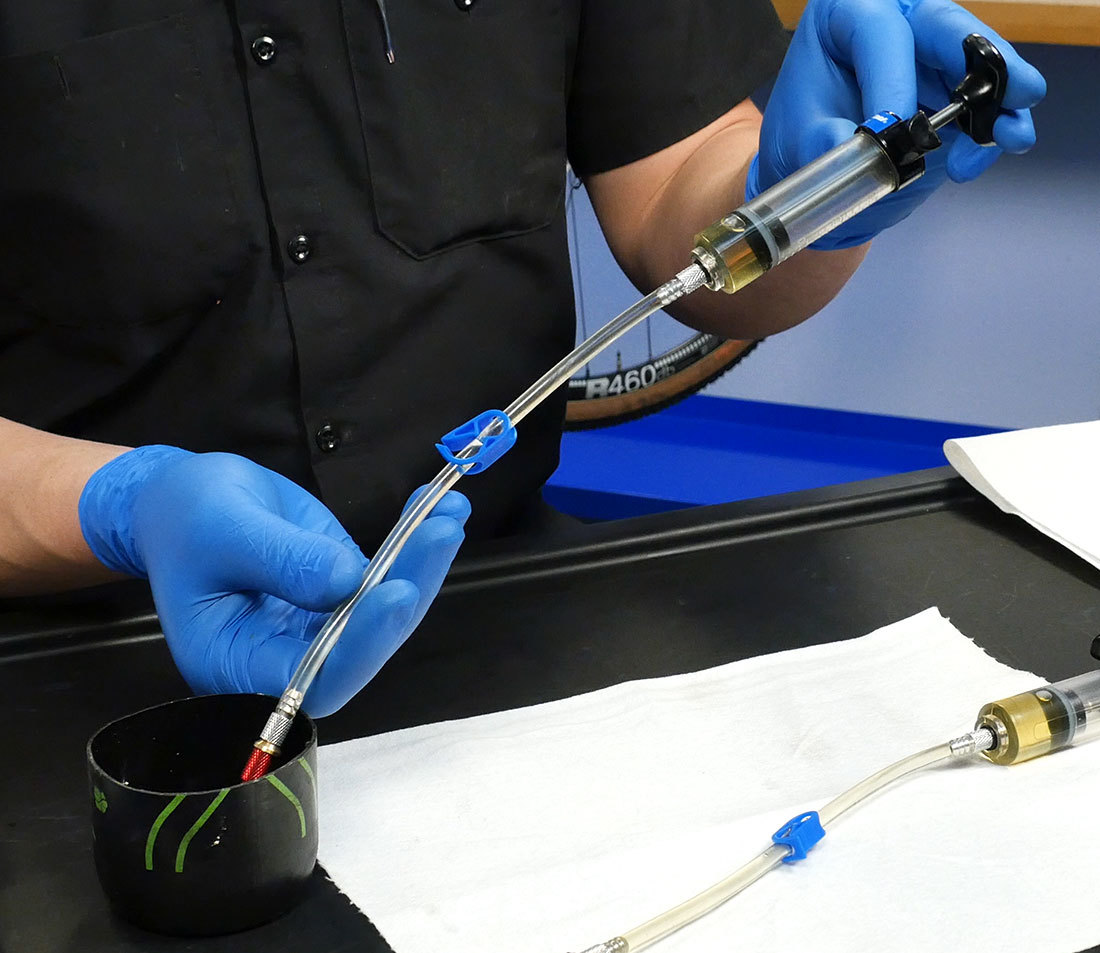

- After bleeding, clear the syringes and hoses of all fluid.

- To prolong the life of your bleed kit, it’s recommended to clean the whole system with alcohol. Start by running alcohol through the hoses.

Empty spent fluid into appropriate container

Pour alcohol into syringe assembly and run back and forth

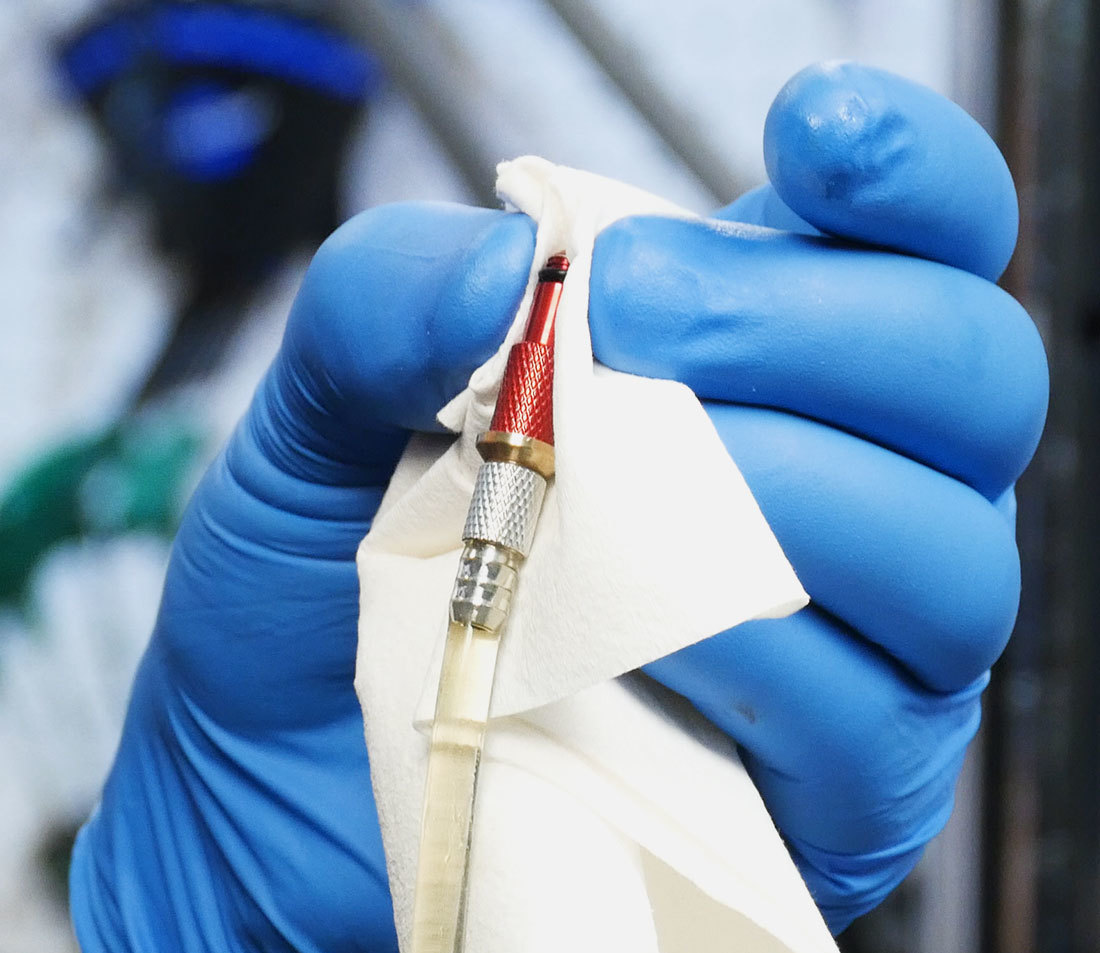

- Disassemble the kit and wipe down each piece, especially the parts that came into contact with DOT fluid.

Thoroughly clean all threaded ends

Thoroughly wipe all surfaces