Bottom Bracket Identification

This article will assist with bottom bracket standard identification. This will be needed when you begin servicing or repairing the bottom bracket.

Preliminary Information

The bottom bracket is the bearing system between the cranks. It sits inside the part of the frame called the bottom bracket shell. The bearings are held in the shell by an adapter or a cup. The spindle connects the two cranks to one another and to the bearings.

In order to service the bottom bracket system, it is necessary to know what type it is. Bottom brackets standards can be difficult to identify. There are many different models that look similar and several different standards.

Additionally, we recommend reading the repair help article at parktool.com on Bottom Bracket Standards and Terminology to get a basic understanding of the different bottom bracket shell types and the bottom brackets that can be installed into them.

Although in some cases, the bottom bracket type can be identified while the bike is together, it is sometimes necessary to first remove the cranks to perform a better inspection. NOTE: There will always be new standards and new tool fittings coming out. You may need to contact your manufacturer or visit your local bike shop for more information.

The basic bottom brackets reviewed here are:

- Press Fit

- Threaded

- Thread-Together (Thread-Thru)

- Campagnolo® Ultra-Torque®

- One-Piece Crank

Press Fit

Press fit bottom bracket systems use a frame shell with a smooth bore, without any threads. Adapters or cups containing bearings are pressed into the shell. There will be no tool fittings visible from the outside in a press fit system.

The thread-together system will also install into a press fit shell, but these are treated as a different system.

For service see Bottom Bracket Removal & Installation: Press Fit.

Threaded

Threaded parts such as those used with threaded bottom bracket shells require tool fittings to turn and tighten. Tool fittings can be external notches, internal notches, internal splines, pin holes, or wrench flats. Bottom brackets for threaded shells can be broken down into three separate systems:

- Adjustable Cup-and-Cone

- Cartridge-Style (Integrated Spindle Systems)

- External Bearing (Thru-Spindle Systems)

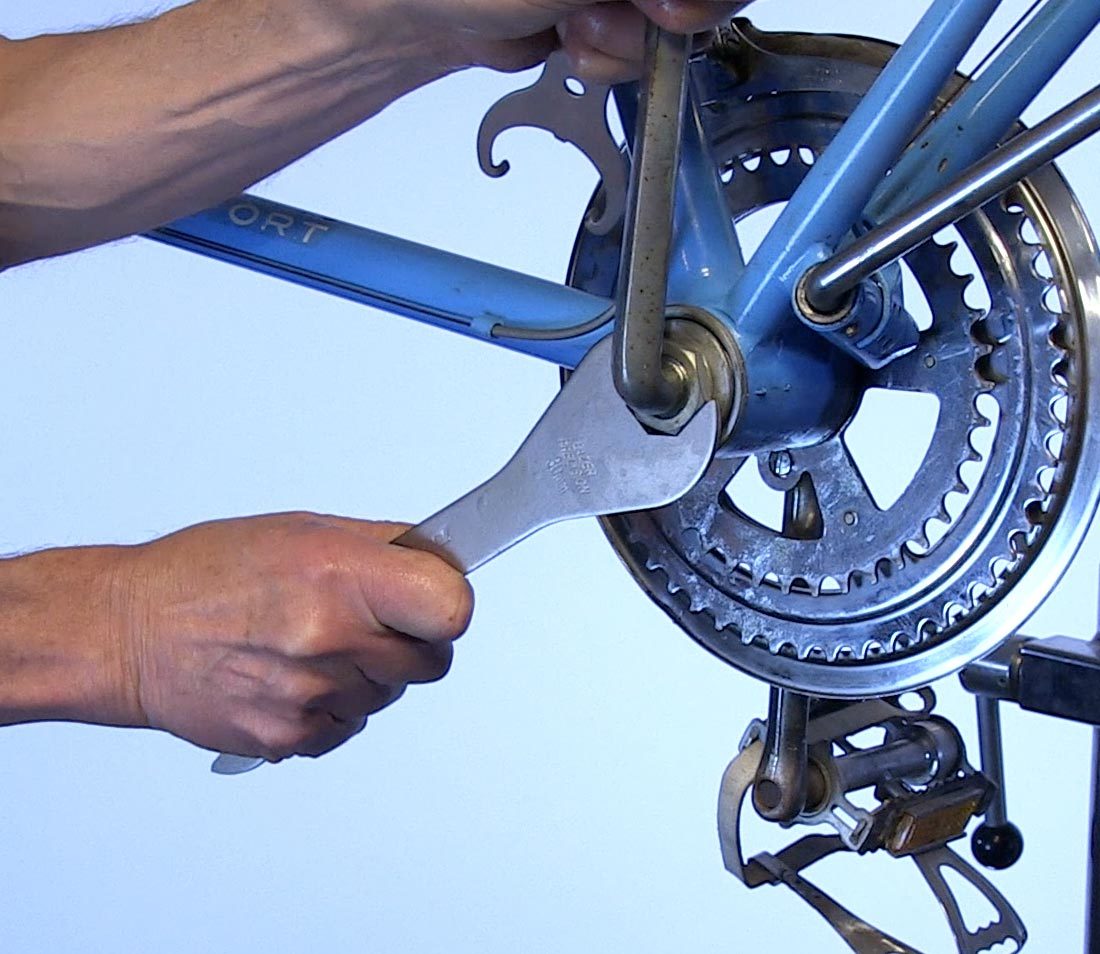

Adjustable Cup-and-Cone

Cup-and-cone style bottom brackets feature two tool fittings on the non-drive side, one of which is a notched lockring that is separate from the cup. These fittings allow for bearing adjustment, which is unique to this system. These bottom brackets can be disassembled down to separate spindles, bearings, and cups. There are both square spindles and round spindles in the ISIS Drive and Shimano® Octalink® styles.

For service see Bottom Bracket Service: Adjustable Cup-and-Cone.

Cartridge-Style (Integrated Spindle Systems)

Some bottom brackets feature a spindle integrated into the bearings as a self-contained unit. These are commonly referred to as cartridge-style bottom brackets. Threaded ends or cups hold the unit secure in the frame shell.

For service see Bottom Bracket Removal & Installation: Threaded.

External Bearing (Thru-Spindle Systems)

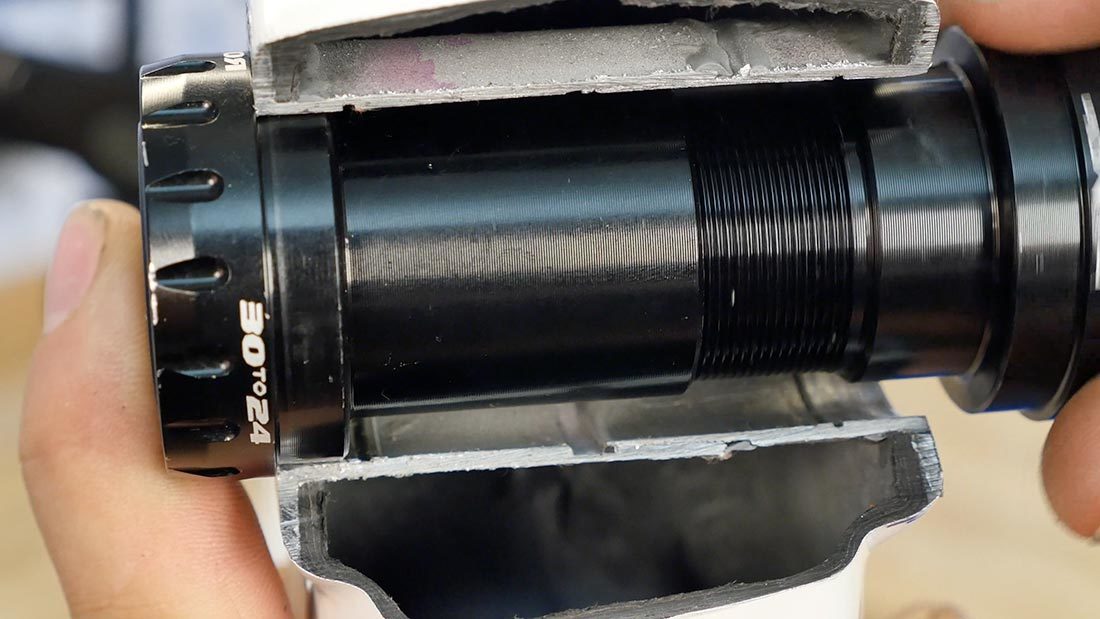

Threaded thru-spindle bottom brackets are comprised of a cup with a cartridge bearing. The bearings can be inboard or outboard of the bottom bracket shell. These bottom brackets are threaded into the frame and then the crank spindle is passed through the bearings.

For service see Bottom Bracket Removal & Installation: Threaded.

Thread-Together / Thread-Thru

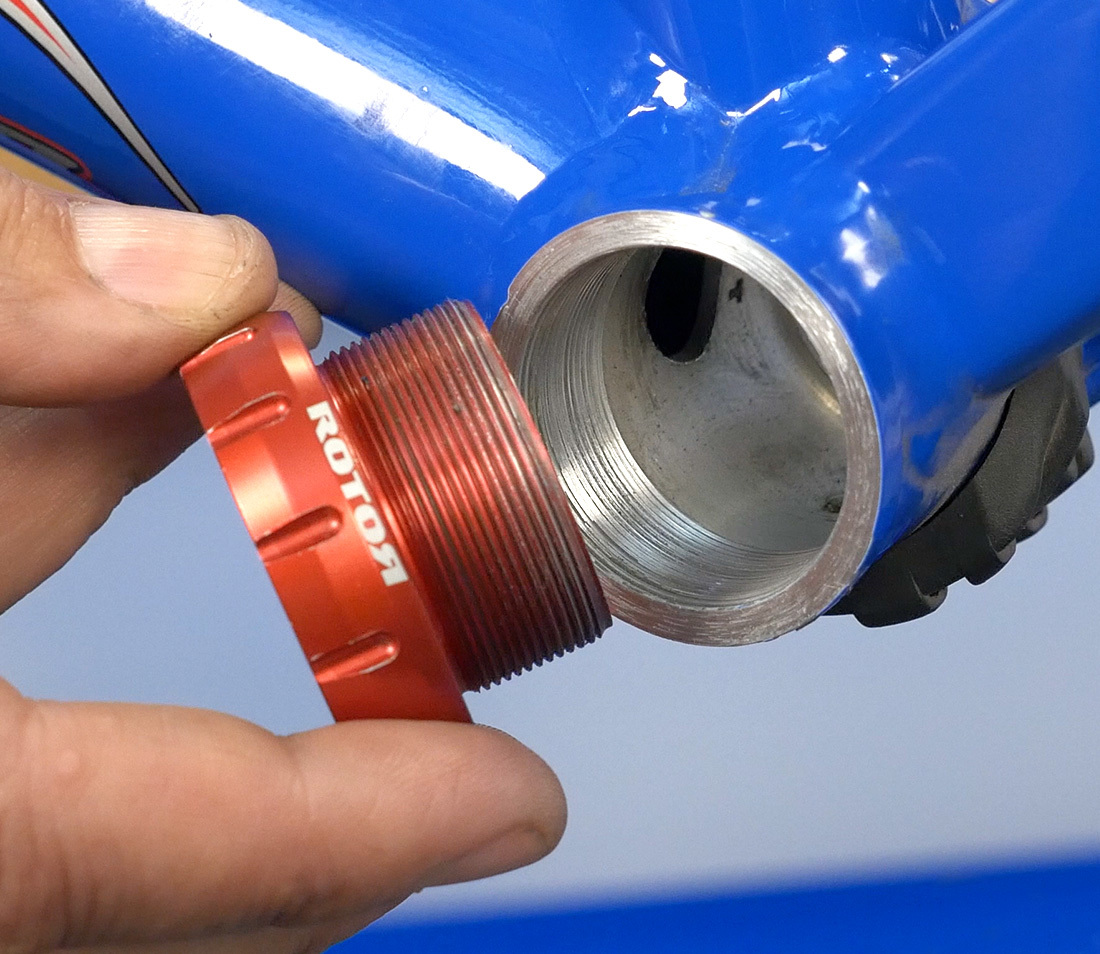

A thread-together bottom bracket, also called thread-thru, is similar to a press fit in that it installs into a non-threaded shell. However, the right and left cup have tool fittings because the two pieces thread together inside the shell. It can be confusing to differentiate these from some bottom brackets that install into threaded shells, which are visually similar.

For service see Bottom Bracket Removal & Installation: Thread-Together.

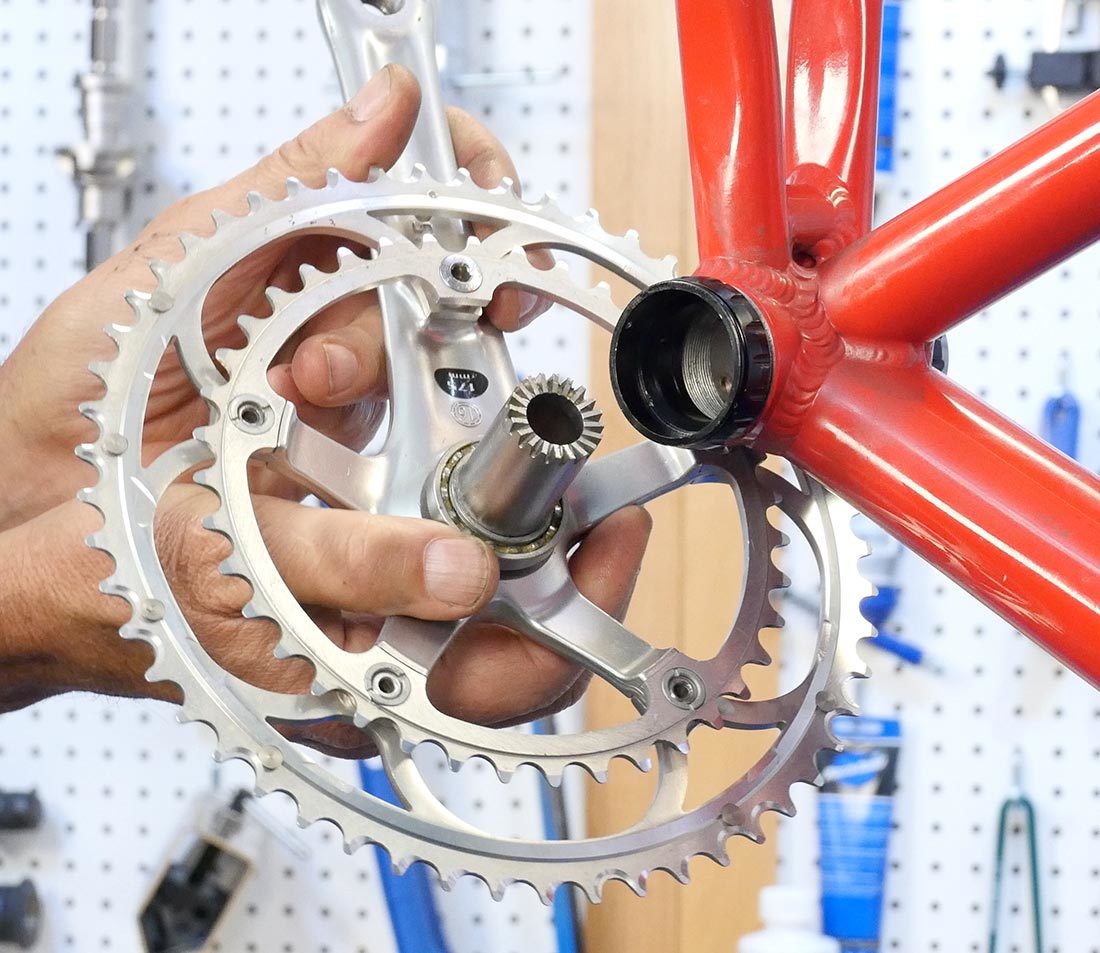

Campagnolo® Ultra-Torque®

The Campagnolo® Ultra-Torque® system is another unique bottom bracket that is easily identified after the cranks are removed. The bearings are installed on the crank spindle after it is removed from the bottom bracket. The bottom bracket cups are pressed or threaded into the shell and are generally not removed unless they are damaged or if one is changing to a different bottom bracket standard.

For service see Crank & Bottom Bracket Removal & Installation: Campagnolo® Ultra-Torque®.

One-Piece Crank

The one-piece crank system, also called the “Ashtabula” or “American Type” bottom bracket, is easy to identify and obvious from a simple inspection. Removing the crank also removes the bottom bracket bearings.

For service see Bottom Bracket Service: One-Piece Crank.