The Park Tool Guide to Bicycle Lubricants and Compounds

A bicycle and its components require appropriate surface preparation in order to ensure optimal performance and durability. This article reviews the types of compounds available and which ones should be used in which applications.

Preliminary Info

A bicycle is made up of numerous parts which come into contact with one another. Ideally, some of these parts should move against each other easily, and some should not move at all. To ensure the correct parts do the correct things, we turn to the exciting world of surface preparation. There are many different compounds that can be used for surface preparation, and they each have their own set of characteristics. This article will give a basic overview of each type, and call out some typical applications as found on a bicycle.

These surface prep compounds all share one characteristic in common: they prevent corrosion and excess wear. When bare metal surfaces come into contact with each other, they will begin to chemically react with one another, resulting in corrosion and rust. Assembly compounds form a barrier between these surfaces, slowing and even preventing corrosion from occurring. With a few exceptions, some kind of surface preparation is always preferable to none at all, and will extend the useable life of your bike and its components.

Park Tool offers 12 different lubricants and compounds, and for our purposes here we will be referring to the relevant Park Tool products in each category; however, especially in the case of lubricants, there are many formulations made by many different companies, each with their own unique properties. Choosing the right one for you may come down to personal preference.

Light Lubricant

In the bike industry, light lubricating oils are usually marketed as chain lubricant. The chain is the component on your bike that requires the most frequent surface preparation — over time, chains will pick up dirt and grime from the trail, and chain lube can be washed off by rain and puddles. For this reason, it’s a good idea to regularly clean and re-lubricate your chain. An insufficiently-lubricated chain will wear out faster and require replacement.

Chain lubes are typically offered in a variety of formulations for specific riding conditions. “Wet” lubes (such as Park Tool CL-1.2 Chain Lube) have a high viscosity and perform well in humid or rainy climates, while “dry” lubes generally attract less dirt and debris, which is especially helpful in dry, dusty climates. Chains can also be lubricated with a wax-based lubricant. To learn more about the merits of these different options, visit a cycling message board or buy your local mechanic a beer.

Although it may be convenient, and it may work temporarily in a pinch, common household penetrating oil such as WD-40 is not an ideal chain lubricant. Do not regularly rely on penetrating oil for chain lubrication.

Light lubricant can also be used in brake and derailleur housing to displace water and prevent corrosion.

Grease

Grease is simply oil suspended in a mixture of surfactant, soap, or other compounds to keep the oil in place, resulting in more durable, long-lasting lubrication. Common all-purpose grease (such as Park Tool PPL-1 PolyLube™) can be used for a wide variety of applications on a bicycle, although other options may be preferable in certain situations as we will cover below. Grease should be changed when it becomes contaminated with grit and dirt or when the oil in the grease becomes old and dry, which reduces its lubricating properties.

Bearing Systems

One important application for grease is bearing systems, such as those found on hubs, headsets, pedals and bottom brackets. Bearing systems that use loose or caged ball bearings, such as cup-and-cone bottom brackets, cup-and-cone hubs, and threaded headsets, rely on grease for smooth operation and minimal excess wear. Optionally, you can use a high-performance grease such as Park Tool HPG-1 with bearing systems. HPG-1 is formulated specifically for bearing systems and features a lower shearing force and higher heat tolerance than all-purpose grease, providing smoother performance under more demanding conditions. The potential tradeoff is durability, as HPG-1 is less viscous than PPL-1 and slightly less water-resistant.

Sealed cartridge bearings have become more common on bicycles — these types of bearings are already greased and are typically not designed to have grease reapplied. In general, sealed cartridge bearings should be considered consumable items and are simply replaced when they wear out.

Threads

Grease is generally an acceptable surface prep option (with some caveats) for threads as found on mounting bolts, bottom brackets, pedals, axle nuts, etc. Grease lubricates threads and allows them to be tightened to the proper amount of torque. It also creates a barrier between components, which repels moisture and prevents galling from metal-on-metal contact.

However, grease is not ideal for threading dissimilar metals together, especially when titanium components or frames are involved. Grease is simply not thick or inert enough to fully prevent the corrosive chemical reactions that occur when two types of metal come into contact with each other. There are other options more suited to these types of situations — see Anti-Seize Compound below.

Grease should also not be used on brake components such as disc brake rotor bolts — the grease can creep outward and cause contamination, which can be a safety issue. Use anti-seize compound or threadlocker.

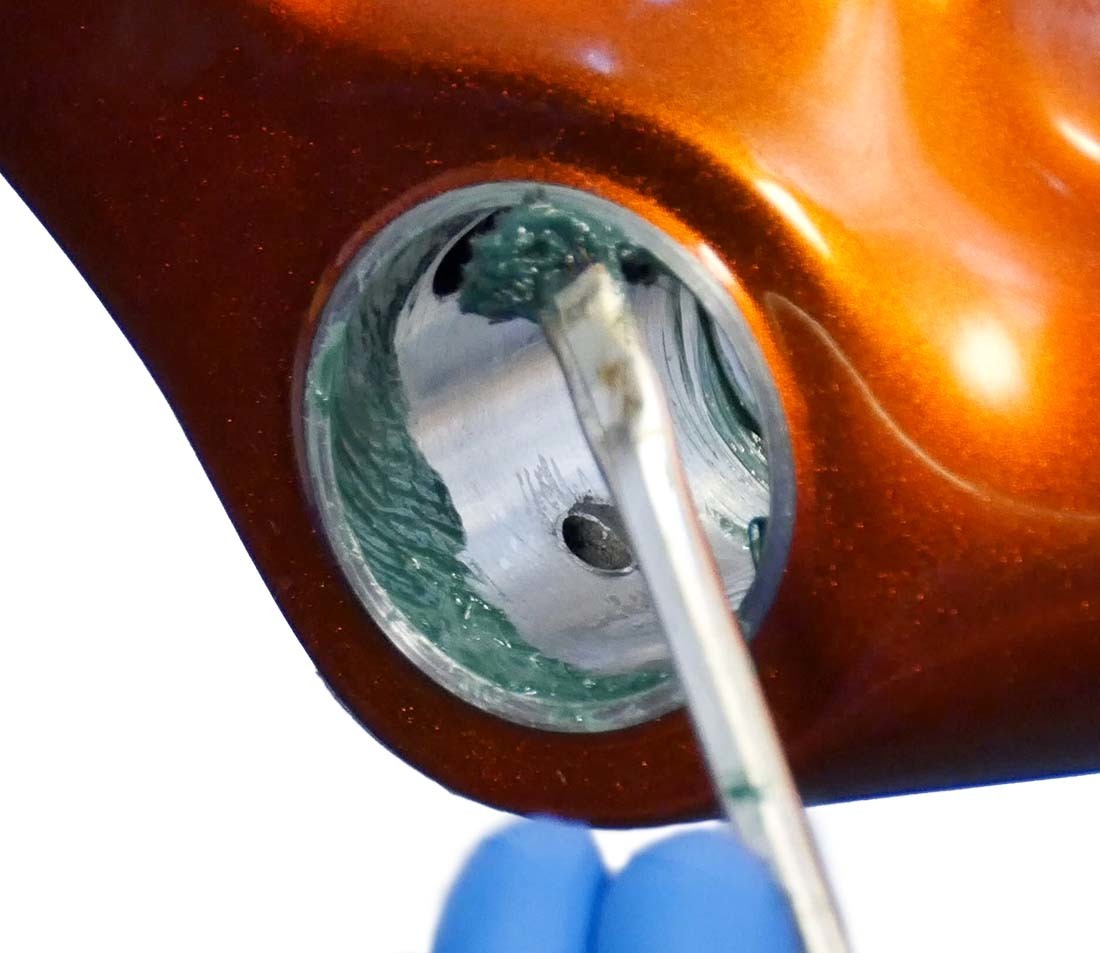

Press Fit

Grease is also a good option for some press fit applications, again with some exceptions. Components such as crown races, headset cups, and bottom bracket cups can benefit from a layer of grease before installation. As with threads, dissimilar materials call for something stronger.

Insertion

When inserting one tube into another, such as when installing a seat post or a quill stem, it is a good idea to apply grease. This will prevent seizing and corrosion, and ease future removal of these components. Apply the grease to the inside of the seat tube or steering column rather than the outside of the seat post or quill stem — this will keep the grease inside the tube, rather than spurting out when the tube is inserted. Carbon fiber seat posts are an exception — see Assembly Compound below.

Clamping

Grease should not be used between the stem and the handlebars, or between the steering column and the stem on threadless systems. These are the rare instances where grease is actually worse than nothing — some of these components are designed to be fastened “dry”. Assembly compound such as Park Tool SAC-2 is often a more appropriate surface prep option for these components — see below.

Anti-Seize Compound

Anti-seize compounds such as Park Tool ASC-1 are typically made of ground metals such as aluminum or copper suspended in a lubricant.

Anti-seize is ideal for surface preparation on threaded and press fit applications, especially between two dissimilar materials. It provides a durable, long-lasting layer of protection that guards against moisture and corrosion more effectively than grease. Any threaded or press fit application where you can use grease, you can use anti-seize compound.

Anti-seize compound is not appropriate for bearing applications.

Threadlocker & Retaining Compound

Threadlockers and retaining compounds are special liquid adhesives for threaded and press fit applications. Commonly-available threadlockers and retaining compounds (such as Park Tool’s offerings) are “anaerobic”, meaning they dry independently of air and will harden and expand when sealed in the threads of the part. This process is what gives these compounds their special qualities.

Primer

When applied before the use of threadlocker or retaining compound, primer will prepare both surfaces and accelerate curing of the compound. When retaining compound or threadlocker is used on carbon fiber frames or components, adhesive primer such as Park Tool AP-1 must first be applied to all component, fastener and frame surfaces. Failure to do so could result in permanently bonded parts.

Threadlockers

Medium-strength threadlockers such as Park Tool TLR-1 are considered “service-removable.” This means the part can be unthreaded and removed with normal service procedures. Medium-strength threadlocker can be used on threaded bottom bracket cups, disc brake rotor bolts, stem bolts, etc.

Stronger compounds such as Park Tool TLR-2 create a semi-permanent bond, and will require extra procedures to disassemble the part, such as mild heating with a heat gun or a hair dryer. High-strength threadlocker should be confined to securing troublesome threaded assemblies, such as fasteners with poor fitment or loose tolerances.

Retaining Compound

Retaining compounds, such as Park Tool RC-1, are intended for press fit applications. Retaining compound can be especially useful to account for poor or marginal fitment on press fit cups and bearings. Retaining compounds tend to have a higher viscosity than threadlockers. Again, be sure to use adhesive primer on both surfaces, especially when dealing with carbon fiber.

Assembly Compound

Assembly compound such as Park Tool SAC-2 is basically a silicon dioxide (sand-like) material in a liquid or paste carrier. Do not confuse an assembly compound with grease! It is not lubrication — in fact, it provides extra friction wherever it is applied.

Although not recommended for press-fit or threaded applications, assembly compound is very useful on clamping applications, especially involving carbon fiber. A common application is on carbon fiber seat tubes that have difficulty holding the seat post secure. It can also be useful on the interface between handlebars and stems.

The grit in this compound will not structurally harm carbon fiber or metal, but you should expect some surface marring.

Other Solvents

Cleaning Solvents

Servicing bicycle components such as the chain, will require cleaners and solvents. Never use highly flammable liquids such as gasoline, kerosene, or diesel as cleaning solvent. Always use purpose-made degreasing solvent such as Park Tool CB-4.

It is possible to reuse cleaning solvents. Save used solvent in a sealed container and allow it to settle for a few days. The dirt and grit will settle to the bottom. Carefully pour off the solvent and reuse. Scrape the grit from the bottom and dispose of it and spent solvent by contacting your local hazardous waste disposal site, which is typically with a state or county agency.

For cleaning the frame use mild cleaners such as a window cleaner, or simply soap and water. Isopropyl rubbing alcohol is usually adequate for cleaning rim braking surfaces. It is important that cleaners for braking surfaces not leave an oily film.

Cutting Fluid

Cutting fluid such as Park Tool CF-2 should be used during any kind of cutting, tapping, facing, or reaming process. It will extend the life of the cutting tool and ensure optimum performance.

When cutting carbon fiber, regularly spray the area with a foaming household cleaner or soapy water throughout the process. This will prevent particles of carbon fiber from going airborne and into your lungs.

Overview Table

The table below is not comprehensive and should not be used as a sole resource for surface prep selection — carefully read the article above, use your own judgement, and if you’re still unsure, ask your local bike mechanic.

✅ = Preferable

🆗 = Acceptable

⛔️ = Not Recommended

| CL-1.2 | PPL-1 | HPG-1 | ASC-1 | TLR-1 | TLR-2* | RC-1 | SAC-2 | |

|---|---|---|---|---|---|---|---|---|

| Chains | ✅ | ⛔️ | ⛔️ | ⛔️ | ⛔️ | ⛔️ | ⛔️ | ⛔️ |

| Cable & Housing | ✅ | 🆗 | 🆗 | ⛔️ | ⛔️ | ⛔️ | ⛔️ | ⛔️ |

| Bearings | ⛔️ | ✅ | ✅ | ⛔️ | ⛔️ | ⛔️ | ⛔️ | ⛔️ |

| Press Fit (Like Materials) |

⛔️ | 🆗 | 🆗 | ✅ | ⛔️ | ⛔️ | ✅ | ⛔️ |

| Press Fit (Dissimilar Materials) |

⛔️ | ⛔️ | ⛔️ | ✅ | 🆗 | 🆗 | ✅ | ⛔️ |

| Threads (Like Materials) |

⛔️ | ✅ | 🆗 | ✅ | ✅ | ✅ | ⛔️ | ⛔️ |

| Threads (Dissimilar Materials) |

⛔️ | ⛔️ | ⛔️ | ✅ | 🆗 | 🆗 | ⛔️ | ⛔️ |

| Bars, Threadless Stems | ⛔️ | ⛔️ | ⛔️ | 🆗 | ⛔️ | ⛔️ | ⛔️ | ✅ |

| Seatposts (Metal) | ⛔️ |

✅ | ⛔️ | 🆗 | ⛔️ | ⛔️ | ⛔️ | ✅ |

| Seatposts (Carbon Fiber) | ⛔️ |

⛔️ | ⛔️ | 🆗 | ⛔️ | ⛔️ | ⛔️ | ✅ |

*Use only for troublesome threaded assemblies, such as fasteners with poor fitment or loose tolerances.