Frame Alignment

This article will discuss frame alignment and the use of the FAI-2 Frame Alignment Indicator. Frame alignment issues and repairs are best addressed by professional mechanics and frame builders. If your frame does not ride quite "right," it is worth having the alignment checked by these professionals.

Getting Started

- Repair Stand — holds bike for measuring, use bench vise for actual bending

- FAI-2 Frame Alignment Indicator

- DC-1 Digital Caliper

- FFS-2 Frame and Fork Straightener (as necessary for leverage)

- Bench vise and steel bottom bracket cups for shell protection

- Angle finder, optional

Frame alignment is also related to wheel dropout alignment. The use of dropout alignment tools such as the FFG-2 is discussed in Dropout Alignment. Generally, dropout alignment should be inspected after checking the frame. Common frame alignment issues arise from the rear triangle being misaligned relative to the front triangle. Procedures to check front triangle alignment are discussed at the end of this article.

Frame alignment is important to the performance of the bicycle. Frame misalignment may result in the following problems:

- Handling and tracking problems, as a result of the wheels not being aligned to the bike’s mid-line.

- Chainline and shifting problems from the rear cogsets being poorly aligned with the front chainrings.

- Difficulty in removing and installing wheels. This can result in slow wheel changes.

However, it is important to keep in mind that a bike or frame need not be “perfectly” aligned to perform well. All manufacturered components and frames are made to certain tolerances. Frame alignment should be checked in order to address specific issues and symptoms. It is not typically measured and addressed as an issue in its own right. If a bike is not showing alignment symptoms, it probably does not need “fixing.”

The Park Tool FAI-2 Frame Alignment Indicator acts much in the same way as a wheel dishing tool. One side of the bike is check for symmetry against the other side. If the rear part of the bike, the rear triangle, is off either left or right, it will show by using the Frame Alignment Indicator. In the image below, the left side is being referenced and then compared to the right. The rear triangle on this bike is off toward the left side of the bike’s mid-line.

IMPORTANT NOTE: It is possible to cold-set or re-bend only certain frames when correcting alignment problems. Some frame material may be either too rigid or too fragile to bend. When a frame is to be repaired by bending, you must exceed the “yield” point of the material. The yield point of the metal is the point were the material will bend and then stay permanently deformed. This is also called “taking a set.” In some materials, the point at which it will yield and stay bent is very close to the point where it will simply fail and break. Thin aluminum tubing, as an example, should generally not be repaired by bending. Carbon fiber frames, such as the one seen below, will not take a set. Carbon fiber material tends to simply flex, and then with more and more stress, it will break. If in doubt, check with the frame manufacturer.

There are often other methods to correct problems and issues arising from a misaligned frame. For example, hub spacers can be added or removed for wheel fit into frame. The wheels may be purposely “mis-dished” for better centering to the bike’s mid-plane. Different bottom bracket spindles will reposition chain rings for better alignment to rear cogs.

Procedure for Frame Alignment

Begin frame alignment by measuring the width of the hub over the locknuts. Measure from locknut face to locknut face, where the nuts would contact the frame dropouts. Write this number down for reference.

Measure over locknut distance

Measure inside dropout width of frame

Measure inside the width of frame dropouts and compare this to hub. If the frame is too wide or too narrow as compared to the hub, it may be awkward removing and installing the wheel. Generally, the frame and hub should width within 1-2mm.

Also note the left and right dropout thickness. If either side is different, record the difference and account for this difference when measuring the frame. For example, the replaceable hanger seen here makes the right dropout effectively 2mm thicker than the left side. When this example frame is centered, the FAI-2 will show a 2mm gap between the pointer and left side dropout.

Place the long straight portion of the FAI-2 along side the left side of the head tube and the seat tube. Make certain the indicator rests on the tubes themselves, not head lugs, welds, bottle cages, etc. Slide the adjustable pointer as necessary to adjust for variations in chain stay length. Turn the pointer knob until the pointer contacts the dropout face.

NOTE: Large down tubes on small frames may make it difficult to contact head tube. In these cases it is possible to extend the width of the head tube by holding a shim, such as a hex key wrench, held flat against head tube. This allows an accurate measurement from the head tube. Additionally, some bikes have no seat tube. In these cases, it may be possible to lower the seat post and use the seat post as a representation of seat tube.

After referencing the left side of the bike, compare this setting to the right side. Set the FAI-2 to contact the same three points on right side, mirroring the tool placement at the head tube, seat tube, and rear dropout. There are two possible results of this comparison:

Result #1: With the FAI-2 contacting head tube and seat tube, the pointer sits directly on right dropout. This frame would be considered nicely aligned left-to-right. Even if there is a small gap between pointer and dropout (under 2mm), it means a wheel will sit within 1mm of center, and the frame is still is good alignment.

Result #2: With the FAI-2 pointer sitting on right dropout, and the FAI-2 contacting the head tube, there is a gap between seat tube and FAI-2 indicator. The dropouts are off to right of mid-plane. In this case, if the pointer is made to contact the seat tube, the pointer will sit inside the dropout, and not on its outer surface.

The rear stays in Result #2 are off toward the right side of the mid-line. In this situation, reset the FAI-2 to referece three-point contact at head tube, seat tube, and dropout on the bike’s right side. Move FAI-2 to check the left side of frame. A gap will now be seen between the pointer and left dropout. Seeing the error at the dropout the dropout rather than the frame.

To cold set the frame, it is best to hold bike securely by the bottom bracket. A simple method to do this is to remove the bottom bracket, and install steel adjustable-type bottom bracket cups. Both cups should extend past shell. Mount bottom bracket in the hard jaws of a large vise. The cups will protect the frame.

When bending the dropout and stays, it is best to begin with mild hand pressure. Check progress by rechecking frame width with a caliper and centering with the FAI-2. Increase pressure as necessary.

If necessary, use FFS-2 Frame and Fork Straightener. This tool provides a lot of leverage, so use with caution.

When bending a frame, bend one stay at a time as necessary. Always consider hub width and frame width when aligning rear triangle. Use the FAI-2 and a caliper together to help minimize the amount of bending necessary. It is common for the one stay to move slightly when the other stay is pulled. This is because the stays are joined with a bridge near the bottom bracket and on the seat stay. Centering tolerance for FAI-2 pointer-to-dropout gap is generally considered 1-2mm. Adequate tolerance for frame width-to-hub difference is also generally considered 1-2mm. However, bikes can certainly perform adequately with even greater error than these numbers. Check with the frame manufacturer for specific tolerances.

Changing Frame Width

The procedure described above is the same to change the rear dropout width. It is possible to change steel frames from 126mm (a common 6 or 7 speed width) to the wider 130mm. Measure the hub width and measure the inside witdth of the frame. Pull out one side one-half of the difference, checking with the caliper. Pull out the other stay the other half of the difference. Use the FAI-2 to maintain the centering.

Main Frame

The head tube, top tube, down tube and seat tube comprise the “main frame,” or front triangle. Significnat alignment issues are uncommon from this part of the bike. If this part of the frame has become bent, repair is especially difficult, and is not generally recommended.

The axis of the head tube should be parallel to the axis of the seat tube. One method to determine this is a frame table, typically used by frame builders. This is a “surface plate,” on which the bike frame is mounted. A series of measurements are taken to determine alignment. It is the most accurate method for checking alignment.

An alternative and practical method uses an angle finder. Simply mount the bike in a repair stand, or even lean bike against a wall. Measure and note the head tube angle. Compare this to the seat tube angle. If the two are within a degree, the bike should be adequately aligned. For example, if the head tube reads 89-degrees, the seat tube should read between 88 and 90-degrees.

Using angle finder to compare head tube and seat tube

Repair of a misaligned front end is difficult, and is likely to involve extensive force and possibly more damage. It is generally not recommended. Typically, a large mandrel is placed in the head tube. The bottom bracket is held secure in a vise. The head tube is twisted in a direction to counter the alignment problem. This repair is rarely sucessful, and the bending places a torsional or twisting load on the top tube and down tube, especially at the joints. Inspect this bike often for failure of joints.

Frame Failure

The bicycle frame tubing and joints may in some cases fail or break. In some cases, a joint may be poorly made, or the design may simply too weak for the use. Failure may also be the result of a crash, causing the tubing joints to yield and begin failing. The repeated stress of riding results in a “stress cycle,” which may cause cracks and eventually failure. It is also possible that an attempt to repair a bike by re-bending tubing causes failure.

Repair of severely bent tubing from a crash is often impossible or very impractical by re-bending. In welded frames, tubing can sometimes be replaced. If the frame is aluminum, it will often require heat treatment after repair to restore strength lost from the welding of the tubing. Bonded frame repair is best left to the manufacturer.

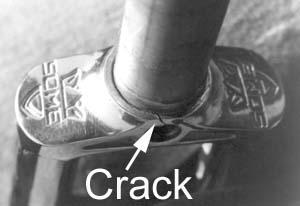

Bicycle frames are best inspected during cleaning. Most types of paint tend to be somewhat brittle and will crack if the material has moved under it. The left image below shows a crack at the bottom bracket shell. The first indication was paint showing the failure. An inspection inside confirmed the crack. The second image is a crack in the left chain stay.

Frame crack along bottom bracket shell

Crack along left chain stay

Composite frames are also susceptible to failure. In the frame below, a metal bottom bracket sleeve was bonded into the frame. This sleeve has loosened from the frame and is creaking.

The downtube of the frame seen below shows signs of a front impact. The tube has a wrinkle under the lower side. The properties of the metal in this damaged area have changed. This tube will likely crack at this point and eventaully fail. The damage in this bike is not repairable other than by tube replacement.

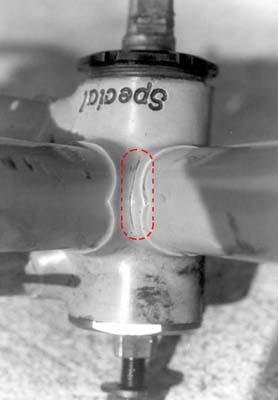

The stress of flexing fork legs is transmitted to the fork crown. This crown has cracked at the narrow material above the brake caliper mounting hole. Fork failure is especially dangerous.