Crank Removal and Installation: Campagnolo® Power Torque™

This article will review the service of the Park Tool CBP-8 Crank and Bearing Tool Set servicing the Power Torque™ crank system from Campagnolo®.

Getting Started

- CBP-8

- Needle Nose Pliers: NP-6

- 14mm Hex Wrench or bit

- Utility Pick: UP-SET

- Hammer: HMR-4

- Torque Wrench

The Power Torque™ crank uses a spindle integrated into the drive side

crank. The left side crank is removed to get to the bearings or to remove the right crank.

Alternative Removal Technique

IMPORTANT NOTE: The Power Torque™ lacks any factory-designed removal design or procedure. The Power Torque™ cranks are very difficult to grab and secure for a pulling operation. There will be inherent risk in servicing Power Torque™ cranks.

For arm removal, consider the alternative removal technique described here.

- Remove right side bearing clip from cup.

- Remove crank bolt and washer. Select the 1198 Extension Plug. Plug is sized to only engage the spindle.

- Insert the plug into the spindle.

- Brace bottom bracket. Have someone assist by holding right side as necessary.

- Use a large mallet to squarely strike the 1198 Extension Plug.

- Spindle is driven right and out of left arm.

- Continue until arm is free of spindle. Expect right crank to fall as it is freed of left arm.

This impact technique does not damage the cartridge bearings in the system. The force is on the spindle and does not pass through the bearings to free the left arm. If the spindle has not been properly lubricated, it can be difficult to remove.

The pulling procedure is described below.

Aluminum Power Torque™ Crank Removal

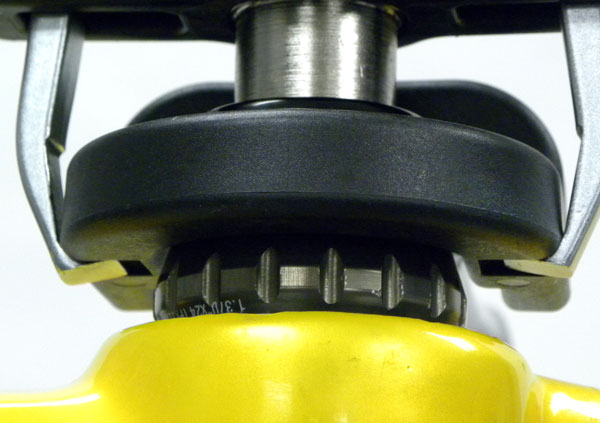

- Remove the clip from the drive side bearing cup. The spindle cannot be removed with this clip in place.

Remove clip from right side bearing cup

Remove crank bolt with a 14mm hex wrench such as the HR-14

- Remove crank bolt and washer using a 14mm hex wrench.

- Slide the plastic molded pad on to the crank. Install the extension plug into the spindle.

- Engage the puller from the CBP-3 set over the molded pad. Align puller and use knob to remove play from the puller fingers. Ends of puller fingers should engage the recess behind the mold. There should be no play between finger and puller body.

Install puller over extension stud and remove play from fingers

Correctly positioned finger ends in pad recesses

- Tighten handle of puller to pull arm from spindle.

- Remove puller, mold, and extension plug from from left arm.

- Pull crank to the drive side and remove it from the bike.

Carbon Arms

The Power Torque carbon and aluminum left side arms are different in shape. Only the aluminum arm uses the molded pad. The back of the carbon arm is flat and provides good engagement with the fingers of the puller. Use only the fiberboard pads to prevent any cosmetic marking of the arm. If you run out of pads, use the pad card as a template and cut new pads from any card stock or thin cardboard.

NOTE: Consider using the ALTERNATIVE REMOVAL TECHNIQUE described above.

The pulling procedure to remove the carbon left arm:

- Remove crank bolt from left arm.

- Install one fiberboard pad, extension plug, and puller.

- Adjust puller knobs until play is removed from finger. Finger ends should engage crank on flat section.

- Turn handle to pull arm from spindle.

Bearing Removal and Installation

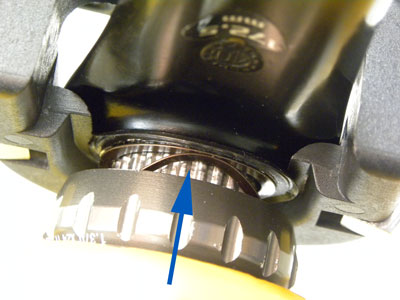

The drive side bearing is pressed to the spindle. There is a C-clip that must be removed before pulling this bearing. The aluminum and carbon arms share the same service feature for bearing removal and replacement.

The procedure for crank bearing removal and installation:

- Use a screwdriver or utility pick and work the clip up and off the spindle.

- Install the bearing remover adapter on the crank. Install adapter aligned with the arm of crank. Push adapter until fully engaged.

- Install puller and engage fingers into arms of adapters. Adjust knobs of puller to remove play in puller.

- Tighten handle of puller to lift adapter and bearing from crank. Inspect the puller and adapter are lifting evenly and not twisting. Readjust as necessary.

- Install new seal and bearing on crank spindle. Place crank on smooth workbench, and place bearing installer over spindle. Use a hammer to drive bearing fully into place.

- Crank is ready to install.

The left side bearing is pressed into the cup. It is Campagnolo’s intention that this entire cup with bearing should be replaced when bearing is worn out.

Crank Installation

Both the aluminum and carbon cranks share the same installation procedure.

- Install crank through right side bearing.

- Install C-clip into pin holes of right side cup.

- Install pre-load spring and seal cover over left side bearing.

- Grease splines of crank. Grease threads of crank bolt.

- Align crank to point 180-degree opposite of drive side arm and install on spline of crank.

- Install crank bolt and secure to manufacturer’s recommended torque.