Bottom Bracket Adjustment Using Preload Ring

This article will discuss how to adjust bottom bracket bearing preload on systems using preload rings.

Preliminary Info

“Thru-spindle” bottom bracket bearing systems pass a spindle through both left and right bearings. The thru-spindles will move back and forth in the bearings and need to be secured to avoid side-to-side play. One design to eliminate movement is a preload ring built into the left crank arm that allows a precise setting of bearing preload.

Adjustment

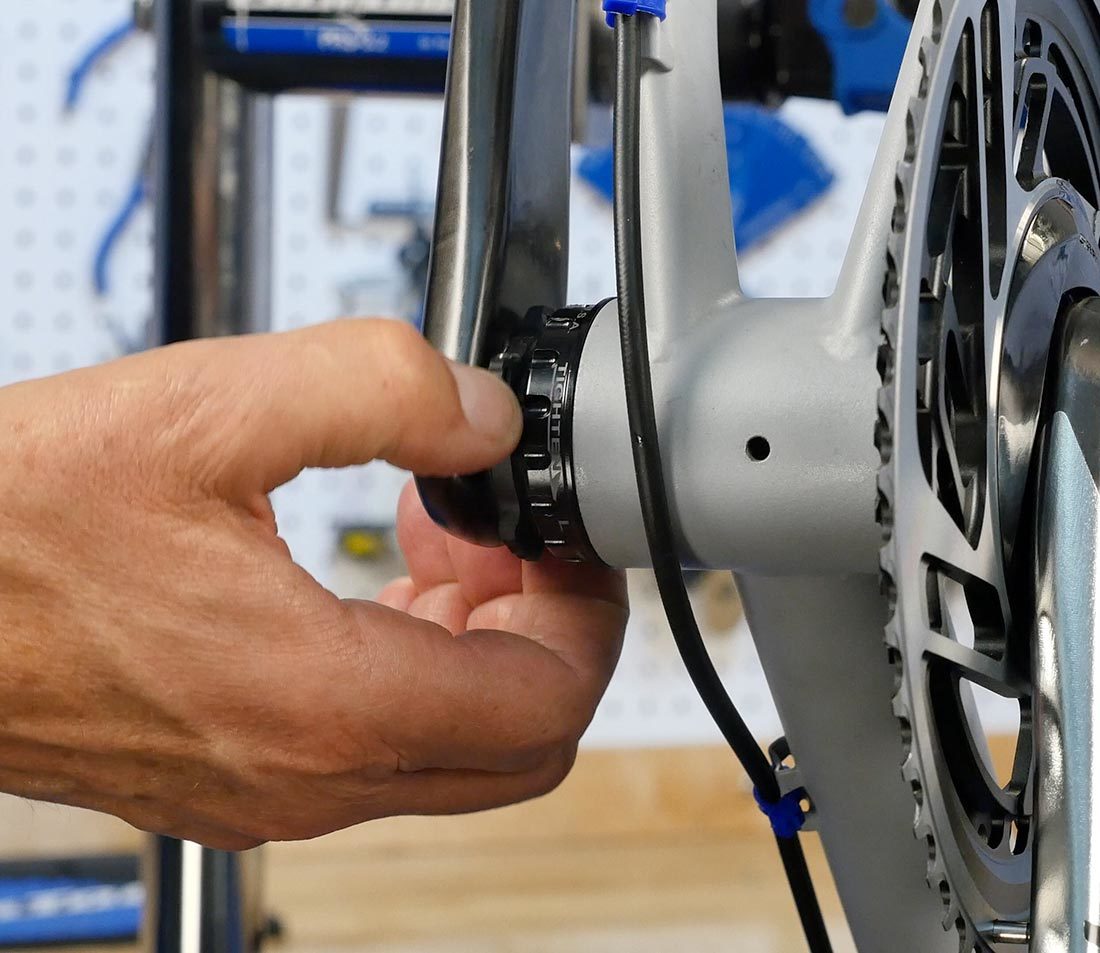

Inspect the left arm for a threaded ring. Loosen any pinch screw or setscrew and turn the ring against the crank. This can be done with the arm on or off the bike.

If the arm was off the bike, install the arm and tighten fully.

Loosen any ring pinch bolt

Tighten ring against arm

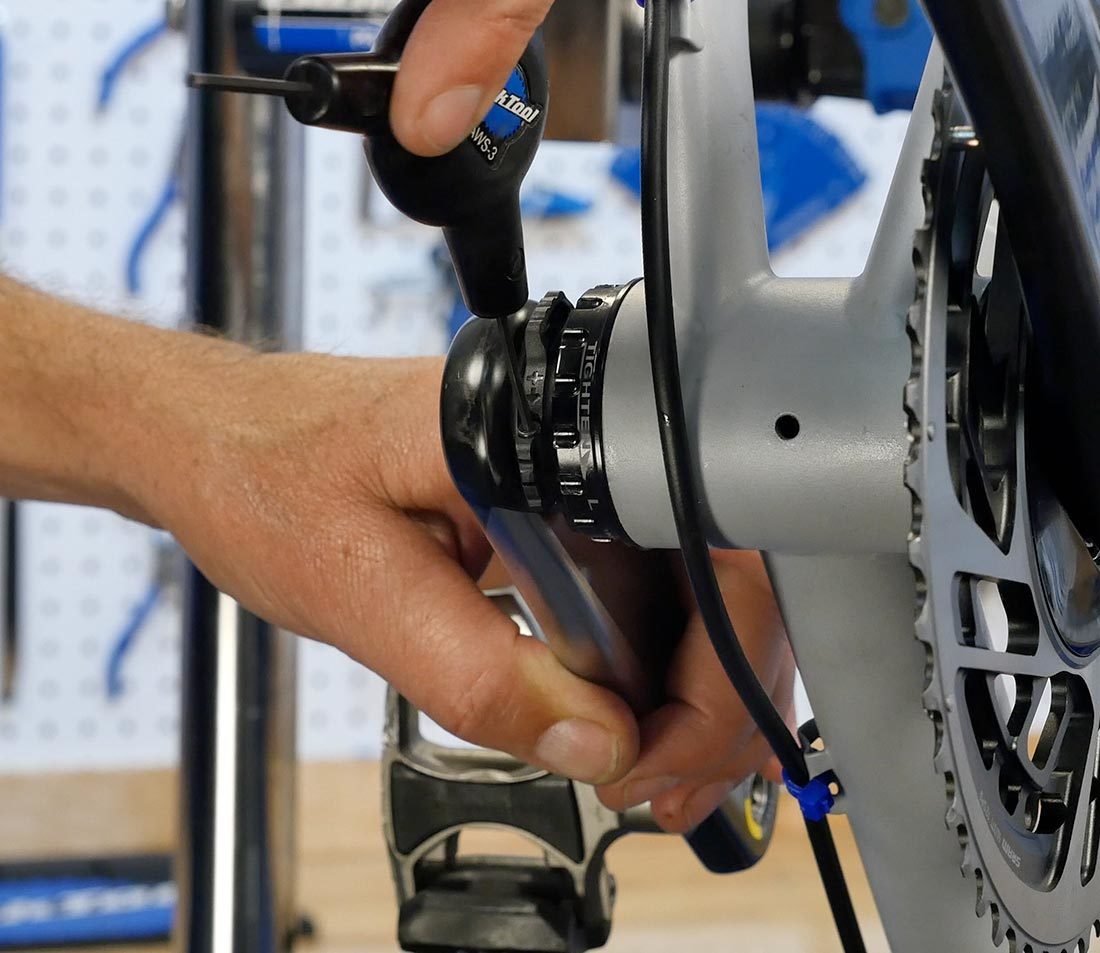

Turn the ring away from the arm toward the bottom bracket until it gently snugs against the bearing.

Secure any pinch bolt in the ring. Only use enough torque to keep the ring from turning.

Some manufactures use a friction system in the ring, and do not use a pinch bolt. Simply leave the ring alone after correctly adjusting it against the bearing.

The preload is adjusted. As a test, push arms left to right along the axis of the spindle testing for side-to-side movement. If movement is present, turn preload ring slightly toward the bottom bracket bearing and test again.