Written by Calvin on January 10, 2013/Calvin's Corner

2013 Cyclocross National Champions

A view of the pit wash area before the power washers arrive

A view of the pit wash area before the power washers arrive

“This year’s USA National Cyclocross Championship promises to be epic!!”—Anonymous Elite Racer.

That might be one way of putting it, because what we are going to be talking about here is a bike race with people wearing spandex, in Madison, Wisconsin, in the middle of January!

This article will be a review of the 2013 USA Cyclocross Championships, January 9-13. This year is a repeat of the same race course as 2012. A year ago we experienced “the winter that wasn’t,” but conditions are much different this year. I will try to update here as the racing develops. If you cannot make it here to see the fun, then be sure to watch the Elite racing on January 13th, Sunday. Watch the rebroadcast here.

Cyclocross racing offers many ways for mechanics to be part of the fun. The team support work offers no end of work. There are many riders here and races going off nearly every hour. Each rider has two bikes and each rider will be needing help during the race. You get to do bike exchanges at full speed, yell lap splits at your rider, elbow out other team mechanics for the best spot, wash the spare bike, and fix it before your rider comes back through the pit again. Having your team rider finish, having him/her give their best effort, and knowing the machine did not get in the way of their results gives a team mechanic a real sense of pride and accomplishment. When your rider podiums, your heart just gets all warm and fuzzy.

However, for me, I find the neutral support roles appealing. I enjoy the positions where your work helps everyone, or at least helps their bikes. During the races I will be stationed at the pit wash area, cleaning bikes, attempting to keep order among the madness, and, from the looks of things, trying to keep myself from freezing. After the day’s racing, I will go help patch bikes back together at the Shimano Multi-Service tent.

The sun is just coming up over the neutral work tent at the course

The sun is just coming up over the neutral work tent at the course

Okay, let’s make something clear up front. We might call what we do here “bike washing” but that is not necessarily a good description. What we do in the pits may get the racers going again and it probably helps them win. But, can the use of gas powered sprayers, with nearly 3,000 pounds water pressure, really be called “washing?” “De-mudding” might be a better term, or perhaps “blasting.” On the other hand, if a person truly cared about the bike, and what was best for the machine... would you even be racing cyclocross? Let us leave this question unanswered for the moment.

Cyclocross is a great sport, but the lure is difficult to articulate. There is speed and grace on two wheels (and comedy as well). Add in a good bit of pain, oh, and don’t forget to add some mud. Sometimes a lot of mud, as evidenced by this year’s race. You just need to be here to get to know CX, or perhaps better, go support your hometown cyclocross racing.

Some early washing below the pit. Wicked Wash staff was there working the washers, making a total of four counting yours truly.

If you are going to help, it better be right here in the pits

The course in Verona, west of Madison, winds circuitously over a hilly prairie. The pits are placed near the middle of a convoluted figure 8. Riders pass their mechanic headed south, and then pedal out across the hills, looping back again, heading north. This allows riders to pass their team mechanics twice each lap. Any help and service by staff must happen here in the pits. You cannot run to your rider outside of this well designated area, even to just put a chain back on a chainring.

There were plenty of bent derailleur hangers, but nothing that the DAG-2 and Max Thomas of Shimano Multi-Service couldn't handle

There were plenty of bent derailleur hangers, but nothing that the DAG-2 and Max Thomas of Shimano Multi-Service couldn't handle

This race used almost a 50/50 course. What is that? The pits were stationed nearly half way. For a good rider, it was four minutes to get from the south-bound pit to the northbound. Then it was four and one half minutes back to the southbound pit again. Say a rider exchanges at one pit, you have 7 minutes 50 seconds to get a workable bike back to the cage. Run down to the wash, but there is a line. I try to kick a bike out in under a minute. With three or four mechanics in front of your, that still works.

Now let’s assume things get nasty, and you need to do bike exchanges every half lap. Now you have 3 minutes 50 seconds to do the same. The smart teams will bring a brush and do a pre-scrub and clear what they can. When we had four washers up and running, and it still might be two or three bikes in front of yours. The big teams with money would bring their own water and power washer. Note to smaller teams: Get a big sponsor.

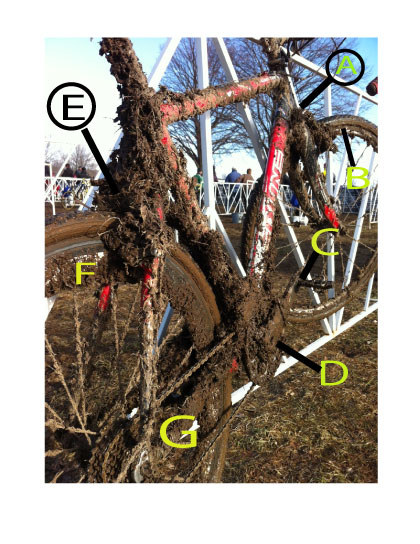

The big bluestem grass was finding its way everywhere on the bikes. This bike did not need a wash during the race.

The big bluestem grass was finding its way everywhere on the bikes. This bike did not need a wash during the race.

The race conditions can change for every race. Friday it began with the ground frozen, even though it rained. The course was slick, but later it warmed up a bit, and we started to see a lot of bikes with grass. Still, all the washers agreed, teams were pitting too much. Bike exchanges take time, even a good one, and if your bike is shifting, braking, and not carrying an extra two kilograms of Wisconsin mud, KEEP GOING AND DON’T STOP AT THE PITS.

Friday was a long day. There were races all day long, and when there wasn’t a race there was a long line of racers wanting a spray. We probably went through 200 bikes, using 3,000 gallons of water. The riders were very appreciative, but then they turned around and rode off in the mud!

After the day is done, time to clean up. What do we use? The power washer, of course.

At first you might think it is a one speed, but a closer look shows it is a broken derailleur hanger

Saturday’s racing, now that was a cyclocross race. Colder today, but the course still muddy. The high was 40, just right for ice to form. We could blast it off, but once they got back on the course, it began to ice up again. When the chain would lock up in a frozen cassette, things could get bad.

Let’s take this bike below as an example of a pit bike between changes. It just came in from a lap, and the rider will expect it again in just a few minutes. We are “washing”, but keep in mind that there is a line of screaming managers/mechanics/fathers/mothers/friends behind us wanting their bikes readied for the next lap as well. The clock is ticking.

So this is what I like to do here. I hang the bike by the saddle, and begin up front, and then work back.

- A—Clear the front brakes, left and right. Don’t forget under the crown.

- B—Clear the front tire by spinning with the blasting water. Do both sides. This saves some weight, but spend only seconds here. If there are cables under the downtube, drag the tip of the gun along the lower part of the downtube.

- C—Pedals, blast and clear right and left side.

- D—Clear the crankset, between rings, and the front derailleur. While here get behind the bottom bracket. Oh, and DO NOT get water in the bottom bracket (JUST KIDDING, man that never gets old, we love that one!).

- E—Clear the rear brake at the pads and up at least to the cable exit.

- F—Blast the rear tires and rim, again just quickly.

- G—Rear cassette and derailleurs, but here blast the rear tire backwards (part of F above). This spins the cassette and chain, so just point the nozzle down and clear the cogs and derailleur. Get the jockey wheels.

Now wait a minute here! What about the seat post, those frame tubes, the spokes? We never said it was going to be pretty, but it is raceable! The idea here not to do a nice wash, but to do literally the minimal necessary to get them going. If you want it pretty, then bring your own power washer!

Sometimes you see some interesting technical problems, but sometimes it is a sadly simple issue. The bike below looks like it might have a horrible dish problem, but the wheel was just installed wrong. The axle was not installed in fully in the left dropout. Yes, it was raced this way until it came to the wash.

No WAG-4 required, just put the wheel in right next time

Hope this weekend's work looks good on my resume

Sunday started out cold. The course was frozen rock hard. With luck, it is so cold the wash pit will be closed, or that is our secret desire. The two early races Sunday had no mud, but then it warmed slightly. The previous race loosened the ground, and now bikes were sticky with mud on practice laps. It was clear we were going to be washing. At least there were two heated power unit. My dreams of sitting in the Polka Tent were dashed.

Randy Niesen of Shimano Multi Service pumping out the alcohol

Randy Niesen of Shimano Multi Service pumping out the alcohol

I am not shy about my lack of tolerance of alcohol in my work areas. The athletes need to know we are giving them the best we can. Save your beer for when the work is done. But there are exceptions to every rule, and in this area, it is isopropyl alcohol that is permitted. We had to blast some bikes due to build up on an ice mud. Our hot water from the washers will quickly freeze, unless displaced. No, beer will not work here, but other chemicals will, including iso-in-a-bottle.

Sunday’s racing did not go as I would have liked, at least not down in the wash. I have been working races for over 30 years, and I still have the same anxiety. My fear is that something on my watch will affect the race results in a negative way. Sunday, just after the start of the women’s elite event, the water tank ran dry. I had check with the crew running the water truck in the morning and asked if we were all set for today’s water, but I did not go and look inside the tank. Another water truck came soon, but for a few laps, the washers were not working. This resulted in a huge pit in my stomach. The mechanics and team were relying on us. We had been there all week for them, and now it was my nightmare scenario. So here is an apology to the riders and staff. Sorry. I should have checked in the tanks myself; another one of life’s lessons