How Wheel Truing Works

Inside the structure of a bicycle wheel, there's a lot going on. Bicycle wheels rely on tension from the spokes to suspend the rim around the hub. Wheel truing is the process of adjusting this tension to affect how straight the wheel spins.

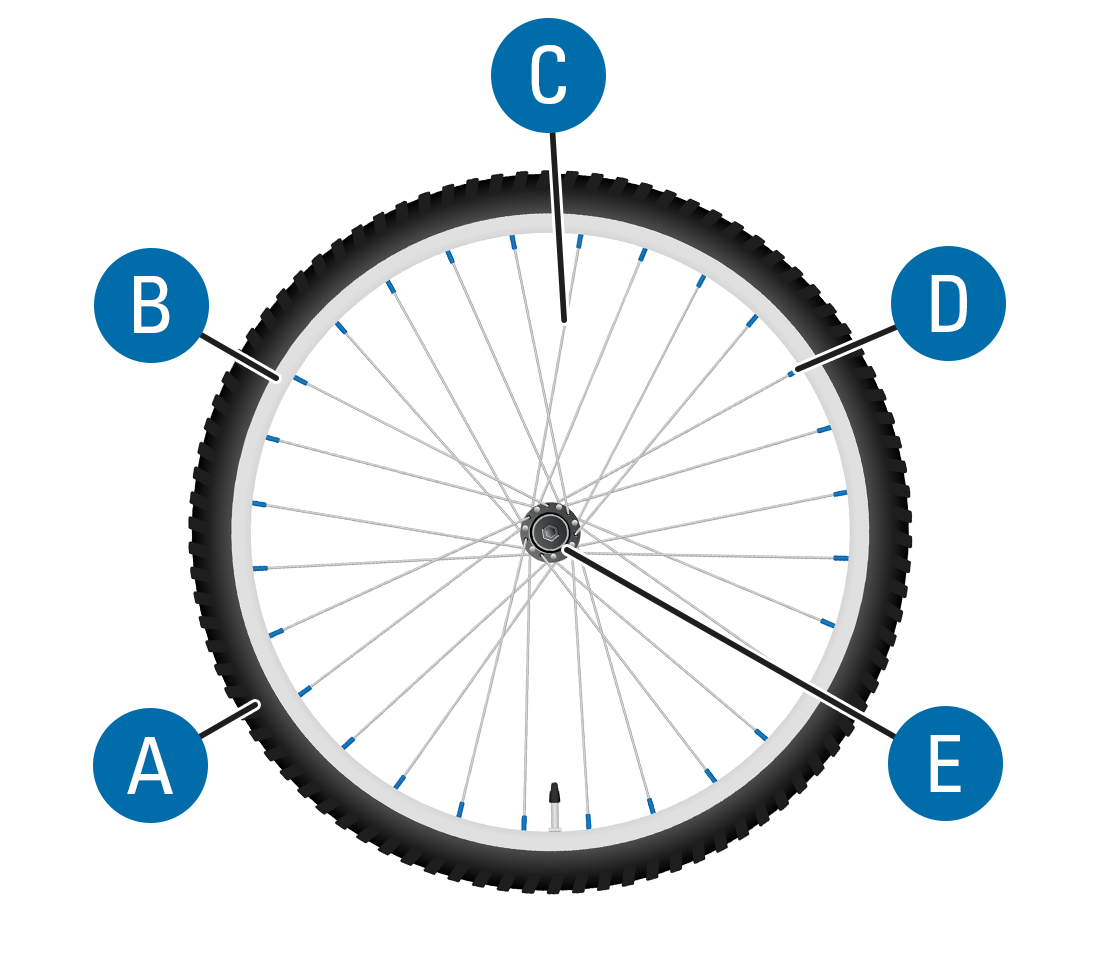

Components of the Wheel

Let’s have a look at the parts of a wheel, and how they all work together.

The wheel is the complete unit with all its components. Starting from the outside, we have the tire, the ring of rubber that provides traction and comfort. Inside the tire might be an inner tube, which acts as a bladder to hold air pressure, or you might have a tubeless system that maintains air pressure without an inner tube. The tire is attached to the rim, which is basically a hoop. Inside the rim is commonly a rim strip, which protects the inner tube from the holes and spokes in the rim. Tubeless tire systems commonly use special tapes to seal the inside so it is airtight. Next are the spokes, which are simply long skinny fasteners, much like a bolt. Spokes typically attach to the rim using nipples, which are the nuts of this fastener system. The other end of the spoke attaches to the hub at the center of the wheel. The hub contains a bearing system that allows the wheel to rotate on the axle. The axle is attached to the frame or fork, and off we go.

Let’s take a closer look at these component parts:

Tire

While we normally don’t consider the tire when truing a wheel, the tire is where the rubber meets the road, and so it is important to the wheel’s performance. If the tire is improperly seated, or has damage to the casing, it can look as if the wheel has a spoke tension problem. This is one reason why it is useful to have the tire removed when you are just learning to true wheels.

Rim

Rims that are made from steel or aluminum begin as a straight channel that is cut to length and rolled into a hoop. The hoop is joined by pins at the seam, or is welded together. Carbon fiber rims are made from a mold. The rim and hub each have a matching number of holes for spokes. Rims are somewhat flexible and actually flatten slightly on the bottom as you ride along. This means the spokes at the bottom will slightly slacken as they pass by this lowest point, but then gain tension again. However, the biggest concern for the rim is not this normal stress of flexing, but the damage a rim might take from impacting things and crashing.

An improperly-seated tire can appear to be an out-of-true wheel

A selection of bicycle rims

Spokes

Bicycle spokes can be made of steel, titanium, aluminum, carbon fiber or threads of synthetic fibers. The most common spoke is steel, which may be either stainless steel or carbon steel. Carbon steel and stainless spokes will be magnetic: carbon steel is strongly attracted to a magnet, while stainless steel is weakly attracted to a magnet.

Spokes are available in different lengths to fit various rim and hub dimensions.

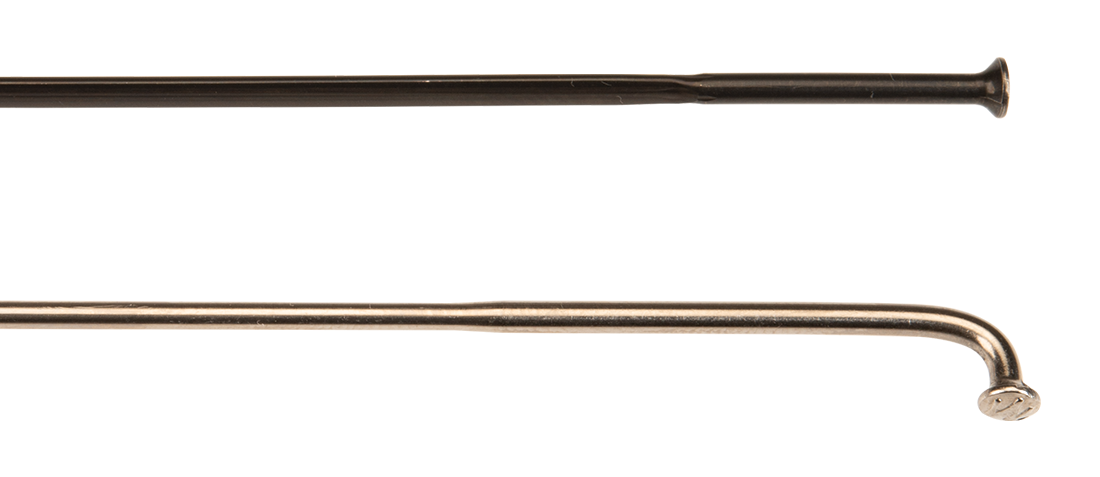

Spokes come in different diameters as well as shapes. Often spokes are the same diameter for their entire length. However, a butted spoke will vary in thickness – thicker at the ends and thinner in the middle.

You may sometimes hear the term “gauge” in reference to spoke diameter. This is an antiquated system that comes from wire sizing, and is inadequate for describing a spoke diameter. The preferred method is simply using measurements in millimeters.

A bladed or “aero” spoke is shaped to give an elliptical or blade-like appearance.

The unthreaded end of a spoke traditionally features a “J”-style bend. The J-bend has a head that is held at the hub flange.

An alternative to the J-bend is the straight pull spoke, which has no bend at the end. Rather, it simply ends in a head, like the head of a nail. Hub flanges must be specially designed for straight pull spokes.

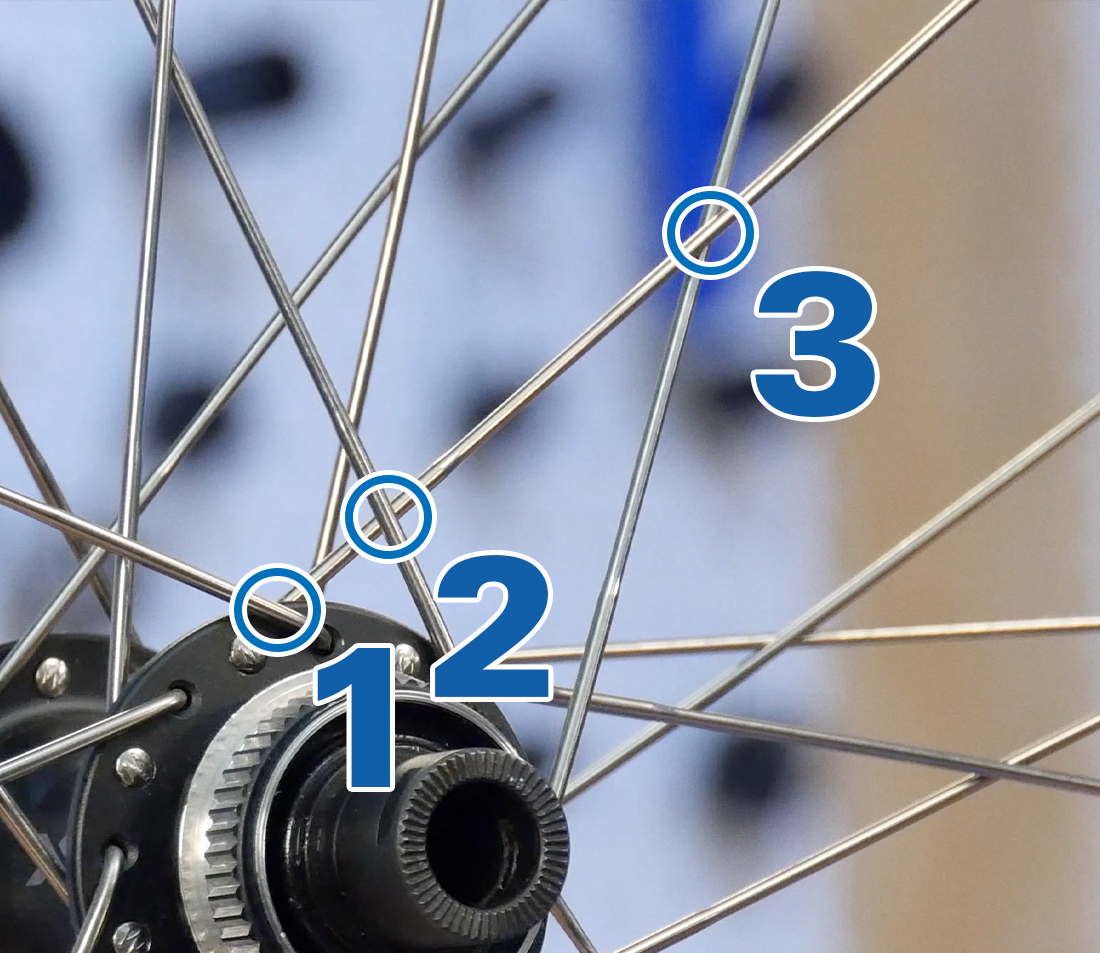

Spokes form a pattern with one another as they connect the hub to the rim. These are called cross patterns or lacing patterns. We count the crosses of one spoke as it travels from the flange to the rim. A lacing pattern that does not cross at all, and is called a “radial” lacing pattern. For purposes of truing the wheel, the lacing pattern does not affect the process.

Spoke Nipple

The nipple is the nut of the spoke system and is used to change the pulling force, or tension, in the spoke.These are commonly attached at the rim. However, there are exceptions.

Most common bicycle wheel nipples uses chrome plated brass nipples. Although less common, nipples can also be made of steel or aluminum.

The most common nipple design has four flats and is turned by using a spoke wrench. There are several wrench size possibilities but the two most common are nominally 3.2mm (same size as the Park Tool SW-0) and 3.5mm (same size as the Park Tool SW-2) when measured across the flats. When determining what wrench to use, it is best to use a caliper to determine the width of the flats. Using a spoke wrench that is too large will round the corners of the nipples so it is important to use the smallest size that fits over the nipple.

Top: an incorrectly fitting wrench that is too large. Bottom: the correct fitting wrench with better engagement.

Measure nipple size across the wrench flats

There are also specially-shaped nipples which require special wrenches. Rims can also be manufactured with the nipples hidden located under the rim strip, inside the rim. These are called internal nipples and require a special wrench to adjust them.

Spoke wrench selection is an important part of wheel truing. See our article on spoke wrench selection for more information.

Hubs

The hub acts as the center of rotation for the wheel. Hubs are commonly made of aluminum and are available in many different widths. The outer body has flanges on the left and right side to hold the spokes. A bearing system in the hub allows the outer shell to rotate around an axle.

Rear hubs feature a mechanism for attaching sprockets. Hubs may also be designed for a rotor disc if the bike uses disc brakes.

The hub is installed in the frame or fork. The three common designs are:

- Solid axle: a threaded axle with nuts on either side

- Quick-release: a hollow axle designed for a skewer with a cam mechanism that applies pressure to hold the wheel in place

- Thru axle: a large connection pin that threads into the frame and is removed from the wheel entirely for wheel removal

Aspects of Wheel Truing

Wheel truing is the process of using a spoke wrench to change the spoke tension to improve the runout or spinning straightness of the wheel. As a nipple is tightened, it pulls on the spoke. Because the spoke material is somewhat elastic, it will flex slightly and pull against the rim and hub, creating tension. When all the spokes are properly tight, they create a pattern of opposing forces that suspend the rim around the hub. The wheel becomes strong and will spin straight if the spokes are correctly tightened.

There are four basic aspects of wheel truing. A professional mechanic is able to adjust spoke tension so that each aspect is optimal. With the right tools, and experience, a thorough wheel truing will produce a durable and strong wheel.

1. Lateral Trueness

Lateral truing is the correction of side-to-side wobbles, or lateral deviations, as the wheel spins. This aspect is the most critical for bicycles with rim brakes. When truing wheels, generally begin first by correcting the lateral trueness.

Adjusting the tension of specific spokes can move sections of the rim to help correct lateral errors. However, there are limits to what changes to spoke tension can accomplish. If the rim metal was bent in a crash or by impact, it may not be possible to get it adequately straight

2. Radial Trueness

The wheel’s roundness, or amount of up and down movement as it spins, is its radial trueness. Radial truing is adjusting spoke tension to correct issues of roundness.

Again, if the metal of the rim was bent from an impact, the results may be limited.

3. Dish/Centering

The two wheels of the bike should be centered in the frame as well as aligned to one another.

4. Spoke Tension

Much like any other fastener system, spokes have a range of acceptable tightness, or tension. Wheels with extremely varied spoke tension will not stay true, or straight, for very long. Additionally, wheels with spokes that are either too tight or too loose overall can cause problems. Spoke tension is best measured using a spoke tension meter (tensiometer) such as the Park Tool TM-1.

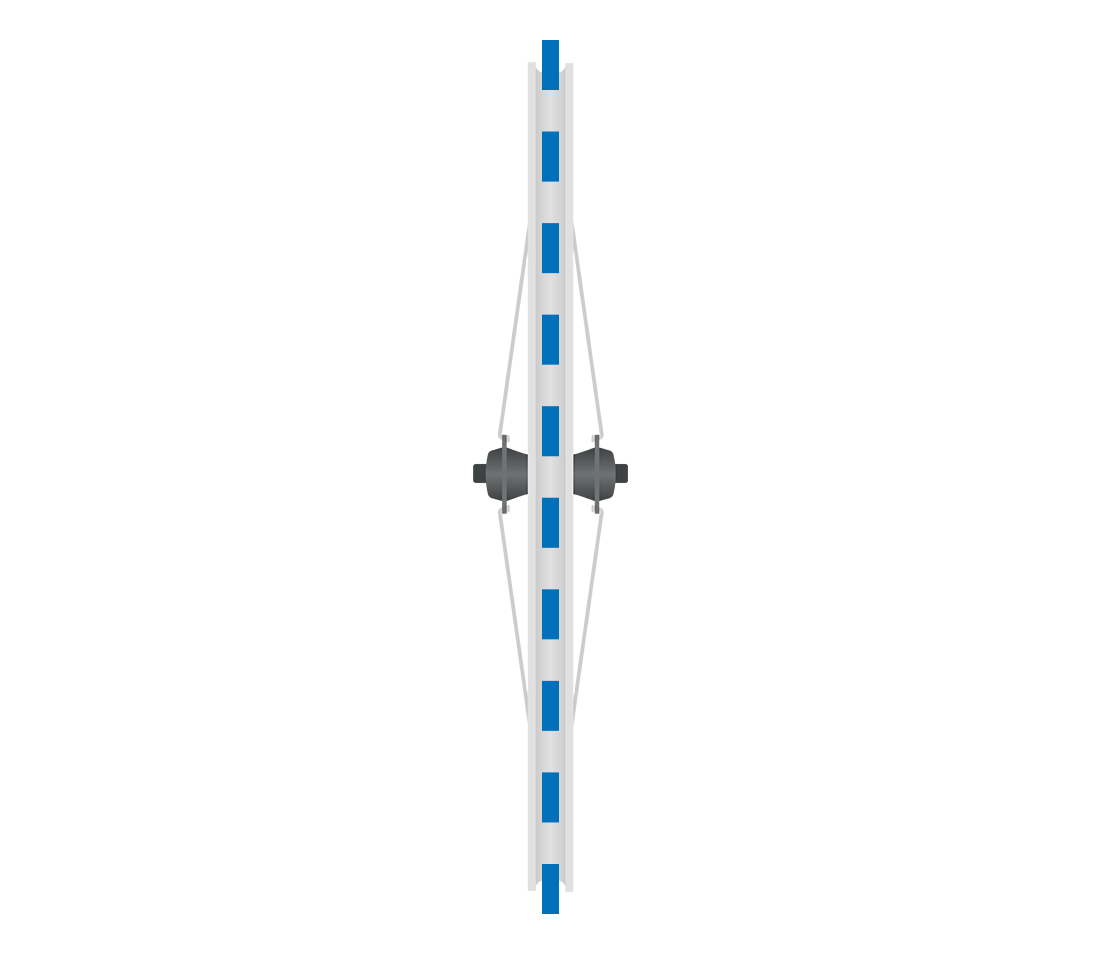

Lateral Trueness (side-to-side straightness)

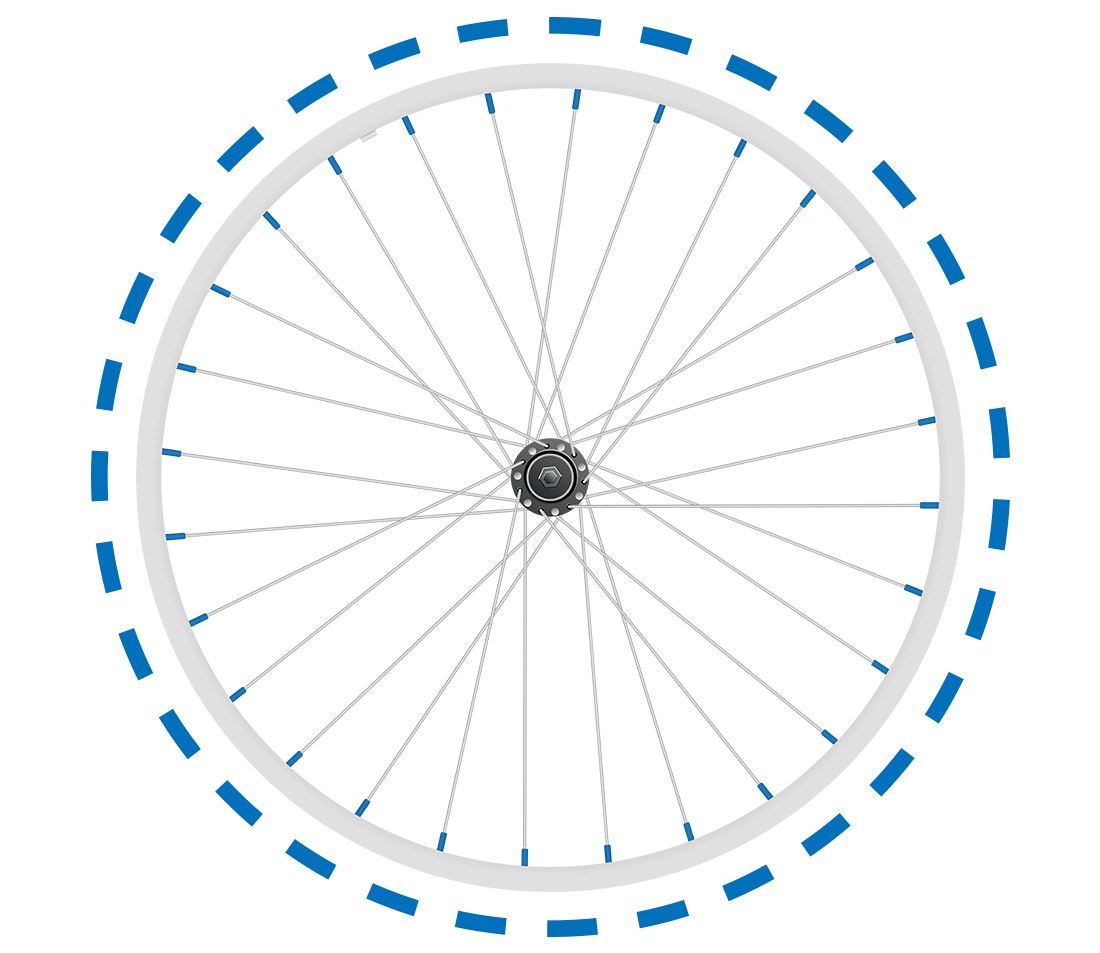

Radial Trueness (up-and-down straightness/roundness)

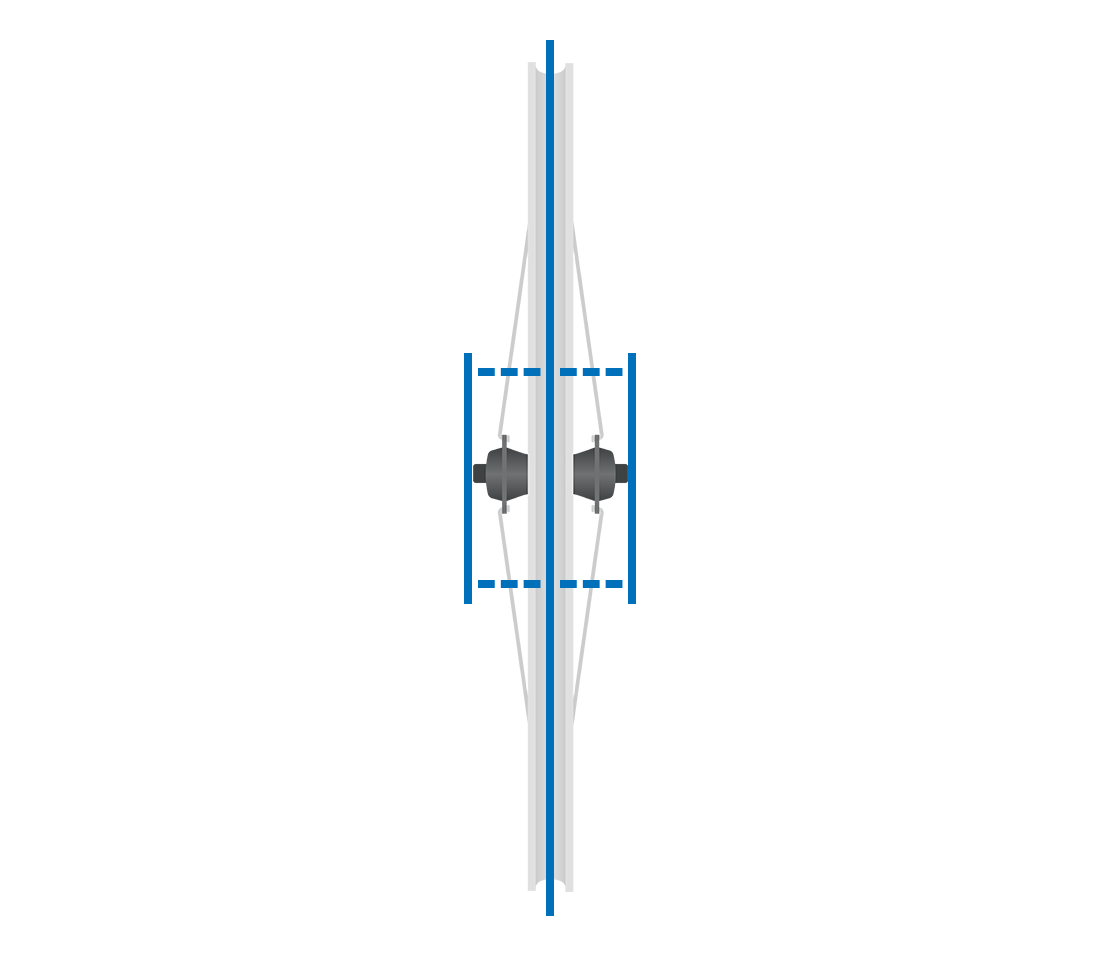

Dish (centering)

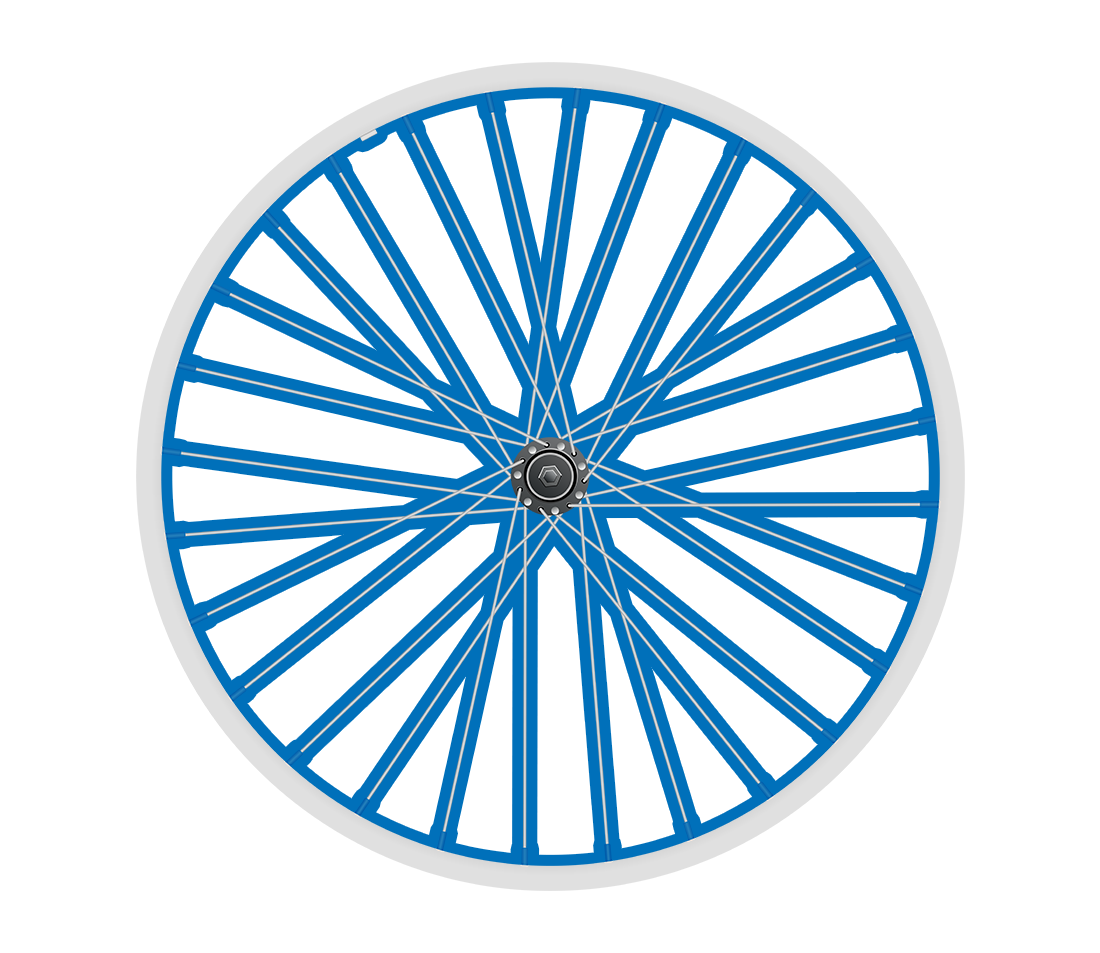

Tension (overal tightness)