Front Derailleur — Advanced Troubleshooting

This article will review the common sources of poor front derailleur performance and how to fix them.

Preliminary Info

Front shifting problems can have many sources. Most problems are resolved by double-checking the basic adjustments. Begin by double-checking the cage height and rotation, the limit screw setting, and cable index setting.

Cable System

The cable system is a common place to find issues that will cause poor shifting. Friction along the shift cable prevents consistent movement of the derailleur as the cable is pulled and released at the shifter.

Dirt and grit can work their way inside the housing. This creates friction along the system, which will slow the shifting both directions. If there is rust, replace the cable.

Inspect the bike for housing and housing stops. If there is bare exposed cable, look at the housing stop for a split or opening. On these bikes you can get a closer look at the cable by putting the bike in the lowest gear, then without pedaling, shift the derailleur to slacken the cable. Remove the housing from the stops.

With the cable free from the housing, slide the housing back and forth to feel how free it slides. You can also wipe the cable and throw on some lube. Put the housing back and see if it helps shifting.

However bikes may also use full housing from shifter to derailleur, without exposed wire or stops. You cannot free the cable in the same way. You will need to loosen the pinch bolt to get a feel for how the cable is operating. If it is difficult to pull the cable back as it is released from the shifter, there is a problem in the system. Typically, the solution is to install new cable and housing.

Also inspect outside of the housing, especially at the ends. Bent housing or bent caps will cause excessive friction. Here again replacement of the housing and the cable is the best option.

An often overlook place for friction is the bottom bracket cable guides. Bare cables may pass under the shell and this contact is not easily seen. If the guides get dirty it will act to slow the cable passage.

Derailleur Alignment & Positioning

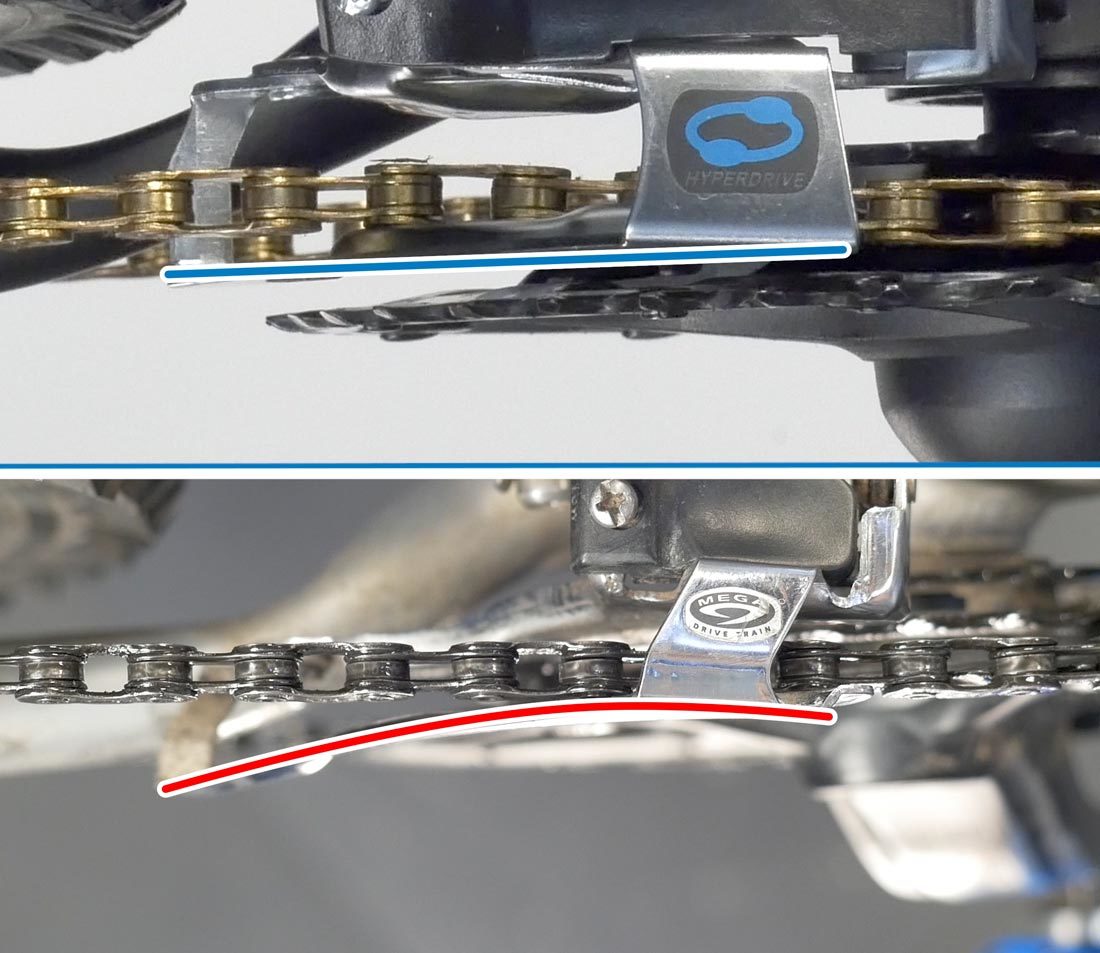

Most front derailleurs can be adjusted for height and rotation. If the cage is set too high over the largest ring, it may not perform well. Too high a cage can cause a slow shift, and can allow the chain to shift over the largest ring. Too low jams the chain into the ring during the shift.

A bent cage can result from a crash or getting the chain jammed at the ring and being forced open by pedaling. Re-bending a cage is difficult. You often end up with multiple bends because it is difficult to isolate the first bend when attempting a fix. Replacement is really the best option.

Normally, the cage is adjusted to be parallel to the chainring. However, there are also times that purposely changing the rotation can help the shift. For example, if the limits are correctly set, and the cage has good parallel rotation, and yet the bike is slow shifting to the smaller rings, it can help to rotate the cage so it is slightly inward. This helps push the chain to disengage it so it can make the shift.

Chainrings

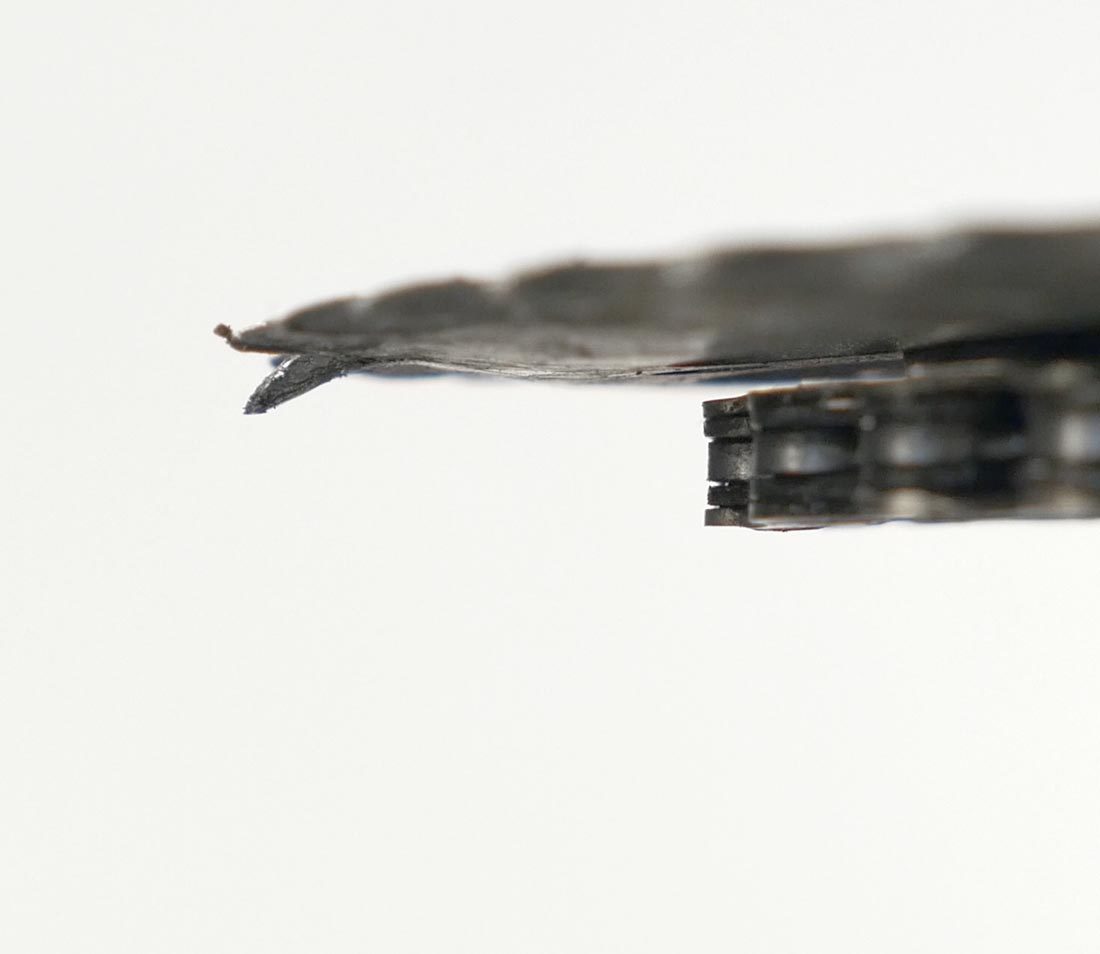

The chainrings will eventually wear and the chain will not engage well on a worn ring. Additionally, the shifting ramp and pin built into ring will become dull and worn out, reducing shifting performance.

A chainring tooth can also become bent as a result of impact. A bent tooth will make a noise and sometimes catch the chain. While replacement is an option, it’s often possible to re-bend the tooth. If a bent tooth breaks on re-bending, you might try it anyway. Even without that single tooth, the ring is likely to work fine.

This movement can be from a loose bottom bracket bearing, so check this.

Another issue is that a chainring can exhibit extreme wobble as it spins. This can make for inconsistent shifts and make setting limit screws and index adjustments difficult. First double-check all mounting bolts are appropriately tight, noting that chainring bolts require significantly less torque than a crank bolt. If the chainring is bent, replacement is the best option.

Incompatible Equipment

Bikes are normally spec’d with compatible equipment. But changes to chainring size or additions of a different front derailleur can lead to incompatibility issues.

For example, if there are changes to chainring sizes the front derailleur may or may not be compatible. Check for proper alignment after the change.

Table of Common Issues

| Shifting Symptom | Potential Problem | Potential Solution |

|---|---|---|

| Chain shifts off of largest front chainring to outside | Front H-limit screw too loose, or rotation of cage is off | Inspect and correct cage rotation as necessary Check H-limit screw setting |

| Chain shifts off of smallest front chainring to inside | Front L-limit screw too loose, or rotation of cage is off | Inspect and correct cage rotation as necessary Check L-limit screw setting |

| Chain shifts slowly or not at all

to largest front chainring | Front derailleur cable tension too slack, H-limit screw too tight, and/or rotation of cage is off | Check front index setting Check derailleur rotation and H-limit screw setting |

| Chain shifts slowly or not at all to smallest front chainring | Front derailleur index setting off and/or L-limit screw too tight, and/or rotation of cage is off | Check front index setting. Check derailleur rotation and L-limit screw setting |

| Chain shifts well to largest front chainring

but outer cage rubs after shift is completed | Front derailleur cable setting too slack | Turn barrel adjuster counter clockwise |

| Chain skips under load at front chainrings | Front chainrings worn | Replace chainrings |