Freehub Service

This article will discuss freehub service for the following brands: Shimano®, DT-Hugi® (some Bontrager), American Classic®, Campagnolo®, Bontrager®, Cane Creek®, and Zipp®.

Getting Started

- Cone wrenches: see DCW and SCW series wrenches

- Combination wrenches: sizes vary

- Hex wrenches: sizes vary

- Shimano®: 10mm

- Current XTR: 14mm

- Various other brands: 11mm or 12mm

- Pencil magnet and seal pick: UP-SET

- Axle vise: AV-1 or AV-5

- Grease: PPL-1 Polylube 1000

- Solvent: CB-4 Bio ChainBrite®

- Compressed air and blowgun

- Rags

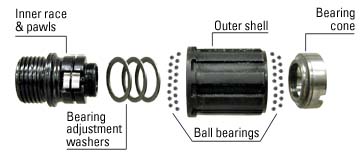

The freehub is the ratcheting mechanism attached to the rear hub of most modern derailleur bike hubs. The freehub uses a splined cylinder to hold the cassette cogs. Inside the freehub mechanism will be bearings and a clutch system, usually ratcheting teeth and pawls. The cassette cogs have no moving parts. All moving parts are in the freehub body.

Most rear hubs allow the freehub body to be removed. The body can then be flushed with solvent for cleaning, dried, lubricated with oil, and then reinstalled. Much of the process is similar to a hub overhaul. To service the freehub, begin by removing rear cogs.

The common Shimano® freehub uses internal loose ball bearing, pawls and springs. Be aware that it is not recommend to completely dismantling the freehub itself. There are no parts available, such as the pawls or springs. The small ball bearings are available as replacement parts. However, if the bearings are worn out and require replacing, it is very likely the entire freehub is needing replacement. The blow-up image seen below is a ball bearing type freehub.

The freehub pawls and bearings operate only while the bike is coasting. There is very little load or stress on the freehub during this time. When the bike is pedaled, the pawls lock onto the ratcheting teeth, and the freehub bearings take very little stress. Because of this, bicycle grease is typically not required inside a freehub. Most manufacturers recommend liquid lubricant for the inside of the freehub. With enough use, the freehub will simply wear out. The pawls may begin to slip and the bearings may become rough. If cleaning and lubricating the freehub does not resolve issue of slipping, sticking or noise, replace the freehub unit with a new one.

Shimano® & Loose Ball Bearing Types

The procedure below is based on the Shimano® freehub removal process. Several other brands follow the same steps.

- Remove axle as during hub overhaul. See hub overhaul if you are unfamiliar with this process.

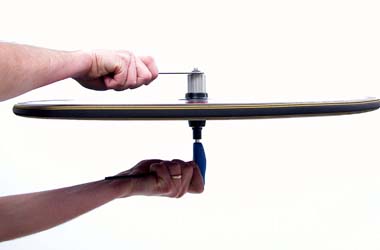

- Use a hex wrench to loosen and remove the freehub holding-bolt. Most brands are accessed through the right side, but a few are accessed through the left side. The bolt is typically very secure and may require much effort to loosen.

- Note any spacer behind freehub.

- Gently remove any seal behind freehub body.

- Flush freehub in solvent, spinning body to remove dirt.

NOTE: Do not attempt to pry out right side dust cap from Shimano® freehubs. Damage may result. Clean under dust cap using a brush and rags. Clean area above cap as well.

- Blow dry with compressed air. Use normal precautions when using compressed air. If no compressed air is available, allow freehub to sit until completely dry.

- Use a liquid lubricant in the back side and front. Spin freehub to work lube inside.

- Grease freehub mounting-bolt.

- Install freehub and any spacer onto hub body. Thread in freehub mounting-bolt and secure fully. Tighten to about 360 inch-pounds. If you are holding a wrench 6 inches from the bolt, apply 60 pounds of effort.

- Assemble and adjust hub as with hub overhaul.

American Classic®

The American Classic® freehub contains cartridge bearings. These may be removed and replaced.

- Hold drive side axle securely in an axle vise.

- Hold non-drive side sleeve nut with cone wrench and loosen locknut counter-clockwise. Pressed-on axle cap will prevent locknut from being completely removed. Make sure locknut is spinning freely and is not engage on thread.

- Loosen sleeve nut. Sleeve nut will press against locknut and act as a press to remove axle cap. Remove cap, locknut and sleeve nut.

- Remove axle by pulling on drive side.

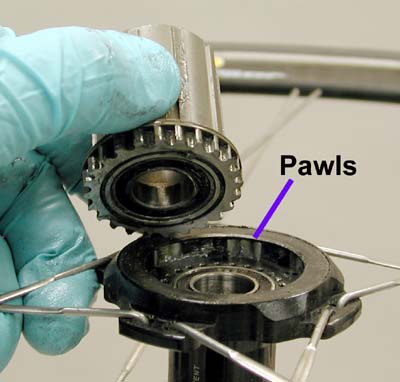

- Pull freehub to remove from hub shell. Pawls are inside hub shell. Clean and flush all ratcheting parts. Use care not to get solvent in cartridge bearings.

- Grease the pawls and teeth of the freehub. Install freehub into shell.

- Install axle and assemble non-drive side parts. Axle should turn smoothly with no side-to-side motion after adjustment.

- Install non-drive side axle cap.

DT-Hugi® (also certain generations of Bontrager®)

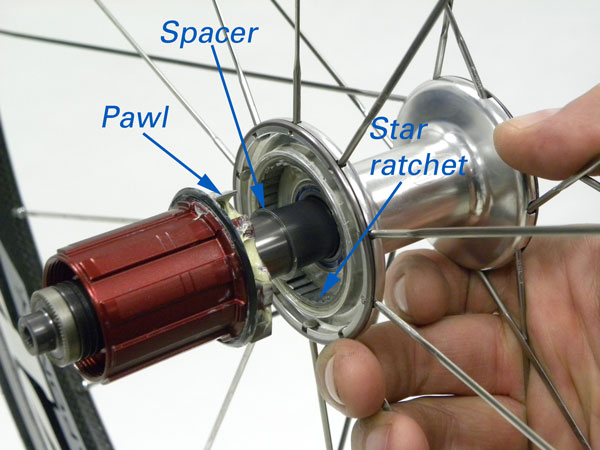

The DT-Hugi® freehub uses cartridge bearings. The freehub mechanism is behind the body.

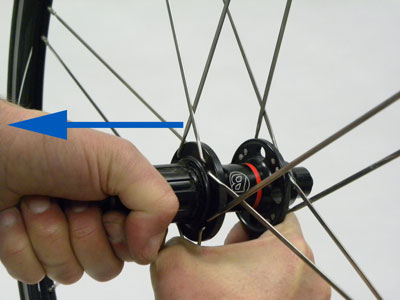

- Pull outward on the freehub body to remove it from hub shell. This will also remove the drive side axle cap.

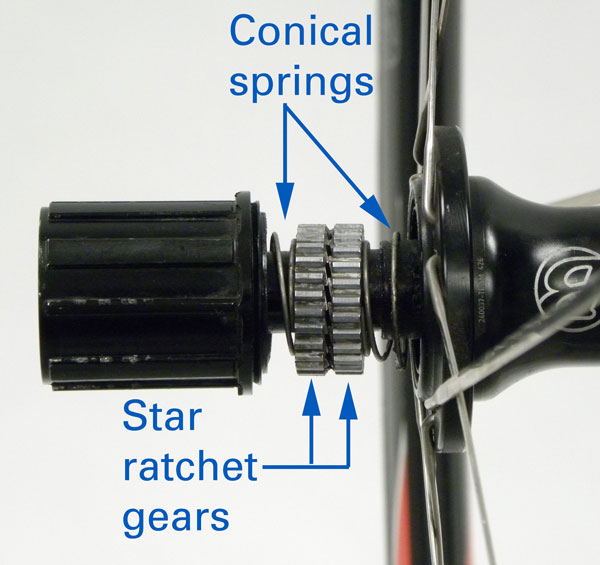

- The clutch is composed of two star ratchet gears. The angled teeth face one another. There is a a conincal spring in the freehub body and another inside the hub shell to push on each star ratchet.

- Clean parts. Use care not to get solvent in cartridge bearings.

- Grease gears and spring.

- Install one gear inside freehub with smooth side facing freehub, and toothed side facing hub shell.

- Install spring inside hub shell, with small end facing toward freehub.

- Install second gear into hub shell, with smooth side facing hub shell and teeth side facing freehub body.

- Slide freehub onto axle and press to seat freehub over seal.

- Install drive side axle cap.

Campagnolo®

Chorus and Record freehubs are held on by the axle. The freehub body holds cartridge bearings. The axle is independent of the freehub.

- Remove set screw from side of drive side locknut.

- Hold non-drive side cone with cone wrench. Loosen and remove drive side locknut.

- Pull freehub to remove. Use care not to loose small parts. Note orientation of pawls as you remove freehub.

- Clean parts as needed.

- Grease springs and pawls, and install into freehub.

- Engage freehub inside hub shell. It can be difficult to engage pawls into hub shell. If necessary use the Campangolo® UT-HU080 tool. You can also tie a string around the pawls to help engage it into the shell, then pull the string loose.

Cane Creek (Aros, Volos, Zonos, Duros)

Cane Creek uses a cartridge bearing system in the hub and freehub.

- Remove quick-release skewer and cassette cogs.

- Loosen left side pre-load adjusting ring setscrew.

- Use fingers to loosen adjusting counter-clockwise, away from hub.

- Insert two 5mm hex wrenches into each side of the axle. Turn right side axle end cap clockwise to loosen. NOTE: end cap is a left hand thread. Remove end cap.

- Pull axle to the left and remove axle from hub.

- Grab freehub and pull it away from hub body.

The installation of the freehub is basically the reverse of assembly.

- Engage freehub into hub body. It may be necessary to squeeze pawls to fit freehub fully into body.

- Install axle into hub body from left side.

- Grease threads of end cap. Thread end cap onto axle. NOTE: End cap is a left hand thread. Secure end cap to 300 inch-pounds.

- Push axle side to side and note any movement. Turn pre-load adjusting ring clockwise until no side to side movement detected. Snug setscrew. Adjustment may also be done with wheel in the frame and skewer loading the bearings.

Bontrager®

The Bontrager hub uses a cartridge bearing system.

- Remove quick-release skewer and cassette cogs.

- The left side of the axle is fitted with a hex hole. Use a 6mm hex wrench to hold the axle. Loosen the axle nut on the right side using a 17mm wrench.

Freehub slides off axle after axle nut is removed.

- Axle can be removed by loosening the left side sleeve nut. Hold axle with a 6mm hex wrench and loosen sleeve nut coutner clockwise. Axle will slide out once sleeve nut is removed.

Freehub ratchet may be cleaned and re-greased. The cartridge bearings may be tapped out and pressed by in with new bearings. If bearings are not to be replaced, do not removed bearings.

Zipp®

- Remove quick-release and cassette cogs.

- Loosen threaded pinch nut on left side of axle. Unthread and remove this nut after loosening screw that hold pinch nut.

- Pull freehub from right side. Freehub and axle assembly will slide out of hub body.

- Use care not to loose pawls, springs and axle spacer behind freehub.

- Clean pawls and star ratchet. Apply new grease such as PPL-1.

- Reassemble parts. Rotate freehub counter-clockwise and squeeze each pawls to engage into hub body ratchet.

- Thread on pinch nut and turn clockwise until contacting hub bearing. Turn counter-clockwise 1/4 turn and secure screw in pinch nut.

- Install wheel into frame and secure quick-release. Test for lateral movement in hub by check for play at rim.

- If play is detected at rim, loosen pinch nut screw and turn nut clockwise slightly and resecure screw.